Steam Heating Slaughter Waste Rendering Plant

Get Price Quote

1 Piece (MOQ)

This model comes in two capacities only. 250 Kg & 500 Kg per batch of rendering. The Digestor of the Rendering plant is directly fired by firewood / coal / briquettes to heat the waste inside to bring it to a temperature where it is sterilized and cooked. In this process it is also homogenized and ultimately vacuum dried before the 'Meat & Bone Meal' is ready for discharge.Features : Environment friendly operation in slaughterhouses Easy to install Carries low pressure consumption

Multi Effect Evaporator

1,600,000 Per Piece

1 Piece (MOQ)

Best Deals from Evaporator

wastewater evaporator

500,000 Per Unit

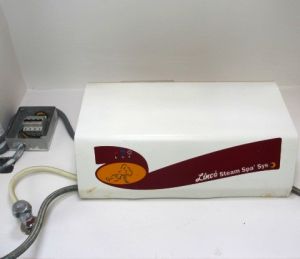

Steam Bath Equipment

Get Price Quote

Stress, body pains, dull and lifeless skin, ageing process can be best prevented by taking steamsauna bath at your home.. Steam and sauna bath benefits •Steam bath Encourages weight loss •Increases Blood Circulation, •Relieves cough & cold, body Pains, Skin Cleansing & Joint stiffness •Steam bath reduces the risk of alcoholism. •Steam and sauna bath Deep cleans & Eliminates toxins, Dust and Cosmetics particles

Industrial Evaporator

1,000,000 Per Piece

Batch Evaporator

Get Price Quote

Batch Evaporator comprises of a falling film short tube (batch) evaporator used for final concentration of glucose syrup. Final carbon treated & pre-concentrated glucose syrup is passed through single effect evaporator to obtain 85~86% solids glucose syrup. This happens under vacuum and vapor is extracted and condensed in a barometric condenser. This range of evaporator is tailor-made to fit the plant capacity. Features Finest qualityReliableCustomizedEconomical Application Starch industries

rotary evaporators

Get Price Quote

Rotary evaporators The RE20 lab rotary machine comes with a compact modular design that keeps operating cost to a low minimum without compensating on performance.Floating Evaporating Flask design to avoid vertical movement of Heating Bath.

Rotary Evaporator

Get Price Quote

1 Set(s) (MOQ)

Rotary Evaporator 2 Liter SENCO Rotary Evaporators are developed by sticking to the basics, keeping in mind safety of the user and focusing on giving desired results. They enable to achieve desired results affordably and are backed by trustworthy service. The Industrial Rotary Evaporator is simple yet accurate, basic yet precise, up to the mark on performance and friendly on budget. These Rotary Evaporators are used for a variety of applications including: Concentration Drying Refining Separation Crystallization

Waste Water Treatment Evaporators

Get Price Quote

We are chiefly engaged in the supplying of Waste Water Treatment Evaporators in all over the country. We offer MEEs (Multi Effect Evaporators), ATFDs, These Waste Water Treatment Evaporators are procured from the reliable sources to ensure their reliability. Our Waste Water Treatment Evaporators are very reasonably priced.Wastewater evaporation is a time-tested method for reducing the water portion of water-based wastes. In its simplest form, the evaporator converts the water portion of water-based wastes to water vapor, while leaving the higher boiling contaminants behind. This greatly minimizes the amount of waste that needs to be hauled off-site.The evaporation process itself involves both a Thermodynamic as well as Mass Transfer.The Thermodynamic Phenomenon of evaporation involves providing enough heat energy to convert water to water vapor.The Mass Transfer Phenomenon of evaporation can best be described as the “carry off” of small droplets of water. These droplets are created at the surface of vigorously boiling water and are “carried off” by oversized blowers or unfiltered water vapor.This “carry off” is problematic with wastewater applications since the droplets of water may have contaminants such as soaps, metals, or oils entrained in them, thus causing an environmental impact outside the building.Evaporation technology offers the simplest and most effective approach to industrial waste water minimization. Wastewater Evaporators are able to handle a wide range of waste streams simultaneously and are a great option for manufacturing processes that may expand or change in the future.Many companies that generate industrial wastewater are hauling their water for disposal at a high cost per gallon. Other companies are treating the wastewater, often with labor and chemical intensive processes, and have to adhere to increasingly strict discharge limits to their local sewer authority. Our evaporators provide significant value and deliver the most efficient wastewater evaporation possible for all levels of output. An investment in one of our wastewater evaporators can save you tens of thousands of rupees over the life of the system.

Evaporator

Get Price Quote

Evaporators are used for concentrating various kinds of Liquid Food, Organic / Inorganic Solutions, Industrial effluents and other liquid products using Thermal Energy. Evaporators can be of Single Effect or Multiple Effect for additional components for heating and cooling. Evaporators are used in industries like Chemical Process, Pharmaceuticals, Bio-tech, Herbal Extraction Plant etc. Vision will design and supply Evaporators as per process / clients' requirement. We can also meet all PED requirements. Salient Features: Designed and Fabricated as Per ASME Sec VIII Div 1 & 2 and TEMA Codes & Standards Material of Construction: SS304, SS304L, SS316, SS316L & MILD STEEL Operating range, Pressure-6 Kg/sq cm2 Comprises of: Vessel, Tube Bundle, required Nozzles, Manholes and instrumentation etc Types: Circulation, Forced Circulation, Falling Film, Single Effect, Multi Effect etc

vacuum rotary evaporator

Get Price Quote

Rotary Evaporator

Get Price Quote

forced circulation evaporator

Get Price Quote

Forced Circulation Evaporator for concentration of high viscosity material and products with higher solids. This is also used as evaporative crystallizer. To achieve desired concentration Falling Film Evaporator followed by Forced Circulation Evaporator is used to minimize the operating cost. In this type of evaporator, the liquid is pumped through tube side of Calandria at high velocity avoiding precipitation and fouling;the liquid is then passed through vapor separator for separation of vapor. Concentrated liquid is continuously discharged from bottom of the vapor separator with pump.

Rotary Evaporator

Get Price Quote

Rising Film Evaporator

200,000 Per Unit

1 Unit (MOQ)

Rotary Evaporator

Get Price Quote

Rotary Vacuum Evaporator

Get Price Quote

vacuum rotary evaporator

78,000 Per Unit

evaporation plants

500,000 Per Box

Multi effect evaporator, atfd, stripper column, vacuum ejector, random tower packing,heat exchanger,reactor.

Evaporators

Get Price Quote

WIRE-ON-TUBE EVAPORATORS are designed for specific use on upright freezers and one combi refrigerators using static cooling refrigeration application. A highly efficient method of cooling the freezer sections of these products which becomes increasingly important as the U.S.A of R134a, hydrocarbon and other refrigerants Becomes more common. Freezer systems are individually designed in Co-operation with customer's design team to suit each model and obtain maximum thermal performance with optimum energy usage. The systems can be delivered with traditional zinc and lacquer protection or Kenmore's exclusive white finish setting new trends in the industry.