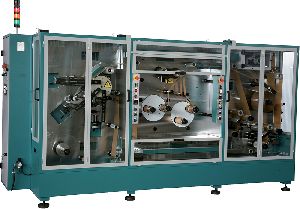

Flexographic Printer

Get Price Quote

1 Pieces (MOQ)

The L36-150 TC-CE model is a semi-automatic flexographic printing press for the 3-colour printing of adhesive tape, the tape cutting and rewinding in preset widths and lengths. Working cycle: the machine unwinds, Corona treats, prints, cuts and rewinds the tape; it slows down and turns automatically the rewind turrets when the preset length is reached. Capable to print: PVC, OPP, ADHESIVE PAPER (Pre-Treated, Solvent, Hot-Melt, Acrylic Water & Solvent Basis) and gummed paper. With an optional device, the machine can also print not adhesive material (not adhesive paper, not adhesive OPP, aluminium and reinforced paper). Advantages printing stations with quick adjustment Exhausting suction system Felt roller to clean the back side of tape Pneumatic pumps for primer and release Primer and release stations Key features 3 colors 3″ mechanical unwind mandrel with dry clutch Tefloned central impression drum (standard) or ceramic central impression drum (on demand) Width and length roll 150 mm – max. diameter 420 mm Slitting device by razor blades Set of spacers for slitting blade holders setting: 12 mm – 15 mm – 19 mm – 25 mm – 30 mm – 38 mm Corona treatment 3 hot air drying tunnels with electric resistors Speed control and adjustment from 0 to 160 m/min by inverter Anti-accident protection preset for the exhaustion of solvents Ventilation system (3 motor fans) Exhaust system (5 suction fans) Printed tape rewinding on change-over turrets Primer station Release station Options ACL50 to print on the adhesive side of transparent tape Coating station to apply primer and release coats Peristaltic pumps for ink trays for the automatic feeding of the ink Pneumatic unwind roller Machine available without Corona Treatment Slitting device with pneumatic score knives for cutting reinforced tape, filament tape or masking tape