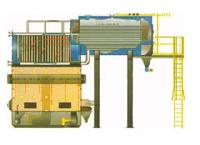

Fluidised Bed Steam Boilers

Get Price Quote

Features The specially designed fire cum water wall in the Fluidised Bed Steam Boilers reduces radiation losses through conventional external furnace Steam Boilers. This improves overall efficiency of the Fluidised Bed Steam Boilers. Reduces work at the boiler site. Reduces civil works and initial capital cost incurred at the Boiler House. Easily convertible to any type of fuel.

Shanti Fluidised Bed Cumbustion Boiler

Get Price Quote

A Fluidized Bed Boiler popularly known as FBC Boilers are designed so as fuel particles are suspended in a hot, bubbling fluidity bed of Refractory Bed materials , through which jets of air are blown to provide the oxygen required for combustion . The resultant fast and intimate mixing of gas and solids promotes rapid heat transfer and chemical reactions within the bed. FBC Boilers plants are capable of burning a variety of low-grade solid fuels, including most types of coal and woody biomass, at high efficiency . In addition, for any given thermal duty, FBCs are smaller than the equivalent conventional furnace Boilers , so may offer significant advantages over the latter in terms of cost and flexibility. Construction FBC Boilers has a water-wall type construction has a steam-water natural circulation system for heat exchange. Vertical in-bed heat exchange tubes are provided and the steam drum of the boiler extends across the full length of the boiler combustion chamber and the convection heat exchange chamber. An air distributor grate is provided for introduction of fluidizing air into the combustion chamber and the air flow therefrom can be controlled to afford a flexible turn-down capability. Model Name : “ Shanti EF-MW-FBC Boiler “ Model No : “ SB-EF-MW-FBC Series Fuels : Husk , Coconut & ground nut shells , Imported Coal , Pulverised Coal Capacities Evaporation capacity : 2000 kg/hr. To 15000 kg/hr. Working Pressure : 10.54 kg/sqcm to 44 kg/sqcm Firing Mode : Automatic Features Wih through combustion due to fluidisation the efficiency is high when compalred to conventional Boiler Fully Automatice right from fuel firing to Ash removal Easy access of maintenace and tube cleaning Balanced draft design for efficient combustion of fuel in furnace Cost Effective in larger capacity Boilers Use of superier quality valves and fittings ensure durability and negligible maintenace Applications Suits all medium and large process industries like Par-boiled Rice Mill , Chemical and pharmaceuticals , co-gen plants , DC Mills , Paper Mills , Textiles , and other process industries where steam requirement is above 2000 Kgs / Hour.

Best Deals from Fluidized Bed Boiler