Timber Cooling Tower

450,000 Per Piece

1 Set (MOQ)

heat transfer system

950,000 Per Piece

1 Piece (MOQ)

Best Deals from Heat Exchangers

Frp Cooling Tower

300,000 Per Piece

Counterflow Cooling Tower

Get Price Quote

1 Piece (MOQ)

Round FRP Cooling Tower

50,000 Per Square Feet

Cooling Tower

Get Price Quote

This 2000 tr cooling tower replaced a mechanical draft cooling tower in the same basin with minor adjustments. Supplied in year 2004. Pay-back period in terms of energy saving was 9 months. The bonus of avoided plant shut-down was additional saving. size: 16.8 x 4.8 x 6.0 water circulation: 1200 cu.m/hr, cooling capacity: 2000 tr

Tube Heat Exchangers

Get Price Quote

Ammonia Cooling Condenser

50,000 - 1,100,000 Per Piece

1 no (MOQ)

AMMONIA CHILLER CONDENSER - chilling engineering Ammonia Chillers, Chilling Plant are compact and skid mounted and are usable for a wide +10℃ to -40℃ temperature range from medium to low temperature process cooling applications, like in pharmaceutical, chemical, dairy, food processing, beverages, cold storage, ice making, industrial gases as well as medium temperature application like HVAC, Plastics, Concrete cooling etc.

Heat Exchanger

Get Price Quote

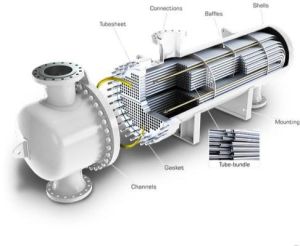

There are many different Types of Heat exchanger available. We provide the following types of Condensers. Shell & Tube Type: GMP Model Heat Exchangers A heat exchanger is a system used to transfer heat between two or more fluids. … Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant.

Stainless Steel Heat Exchangers

20,000 Per Piece

Plate Heat Exchanger

Get Price Quote

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. The major advantage over convetional heat exchanger is that the fluids are exposed to a much larger surface area because the fluids spread out over the plates and facilitates the transfer of heat. A plate heat exchanger consists of a series of thin, corrugated plates and these plates are gasketed, welded or brazed together depending on the application. The plates are compressed together in rigid frame to form an arrangement of parallel flow channel with alternating hot and cold fluids. The advantage of plate heat exchanger compared to shell and tube heat exchanger is it requires less floor area, large heating area, the temperature approach in plate heat exchangers may be as low as 1 °C, increase and reduction of heating area is simple.

Aluminium Straight Fin Anodizing Heatsink

50 Per Piece

Plate Heat Exchanger

Get Price Quote

We are offering the best quality Plate Heat Exchanger that is a type of heat exchanger which uses metal plates to transfer heat between two fluids. Plate Heat Exchanger that we offer has a major advantage over a conventional heat exchanger as in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. Our Plate Heat Exchanger is now common and its very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. Small Plate Heat Exchanger, provided by us, has made a great impact in domestic heating and hot-water. Larger commercial versions of our Plate Heat Exchanger use gaskets between the plates, smaller version tend to be brazed.

Heat Exchanger

15,000 Per Piece

1 Piece(s) (MOQ)

Air Water Heat Exchanger

775 Per Set

Shell and Tube Heat Exchanger

Get Price Quote

Heatsink

Get Price Quote

Fans provide an additional failure point, thereby reducing the system’s reliability. Fans also increase the noise of the system, can introduce dust and contaminants, and require additional power. For any one of these reasons, a system designer may wish to exclude fans from the system and use natural convection heatsinks.Since the air passing over the fins rises upwards as it absorbs heat from fins, the heat sink has to be positioned in a way so as to align the individual fins along the vertical. Also the gap between two fins has to be larger to allow for required air flow. Such constraints have to be taken into account when considering a natural convection (or passive cooled) heat sink for use.

Heat Exchangers

Get Price Quote

HEAT EXCHANGERS are used in refrigeration appliance and can be supplied separately, or as part of the evaporator assembly. Copper heat exchangers features an external capillary soldered along its length - which offers excellent heat transfer characteristics. Various customer's requirements can be accommodated. A choice of diameter 6mm and diameter 8mm copper tube, with numerous end sizes are available to achieve the optimum flow rate. Heat exchangers are manufactured in accordance with ISO 9001/9002 certification, are fully compatible with R134a and hydrocarbon refrigerants.

Heat Exchangers Shell

450,000 Per Piece

1 Piece (MOQ)

Heat Recovery Unit

Get Price Quote

In present scenario of rising fuel prices Shanti Boilers offers wide range of efficient energy conservation products like Air Pre Heaters , Water Pre Heaters , Condensate Recovery Pumps , Pressure Regulating Stations , Thermo Static Steam Trap Air / Water Pre Heaters : Shanti Boiler’s Air Pre Heater / Waer pre Heater are design to utilize the high temperature flue gases and recover it, by either pre- heating combustion air going to the furnace or to heat the water at the ambient temperature to 75-80 deg c . The objective is to harness fully the available heat from flue gases and increase the over all efficiency of Boiler by optimally designing the Heat Recovery Units there by it results in fuel saving for the industry. Model : SB-APH & SB-WPH Series Type: Vertical / Horizontal design

energy recovery ventilators

Get Price Quote

Heat Exchangers

Get Price Quote

Heat Exchangers are used for change of status of materials, such as liquid to gas and gas to liquid. They are used in majority of Process Industries including Chemical, Pharmaceutical, Paint & Coating, Resin Plants, Biotech industries, Power Plants, Petroleum Industries etc. Vision’s designs and supplies Heat Exchangers as per Processes/Clients' requirements. We can also meet all PED requirements. Salient Features: Designed and Fabricated as per ASME Sec VIII Div 1 & 2, TEMA Codes & Standards Material of Construction: SS304, SS304L, SS316, SS316L& MILD STEEL Capacity: Heat Transfer 1m2-100m2 or as per clients requirement Operating range, Pressure-full vacuum to 10 Kg/cm2 Types: Fixed Tube, U-Tube, Single Pass, Multiple Pass, Floating Head, Vertical or Horizontal Shell & Tube Heat Exchanger

Heat Exchangers

Get Price Quote

We offer heat exchangers. We are manufacturer of steam boiler incinerator hot airwater generator thermic fluid heater autoclave bio medical waste shredder burnerboiler & its sparessupplying of synthetic thermic fluid oil

Anodizing Heatsink

Get Price Quote

Air Cooled Heat Exchanger

Get Price Quote

Heat Exchangers are supplied as pre-assembled units for easy and fast installation. The reliable and proven gas cooling technology allows use of recovered heat for drying, combustion etc.. The dust laden air enters the Heat exchanger through the shell which causes ambient air to circulate externally with the help of ID fans causing cooling of temperature. Heavier dust particle drop in to the hopper while cooled gas at 16-180 deg C passes through the Bag filter / ESP. The unique scraping system removes accumulated dust from the tubes for Horizontal tubes Heat Exchanger which causes dust to fall into the hopper and is removed through the discharge device.

Heat Exchanger

Get Price Quote

We offer Heat Exchanger.

stainless steel condensers

80,000 Per Piece

water cooling towers

14,000 Per Piece

Cooling Towers

Get Price Quote

Our company is specialized in manufacturing qualitative range of Cooling Towers that are used in various industrial requirements and are known for easy installation, low power consumption, and cost effective.

blanking panels

114 Per Piece