Two Pin Power Cord

Get Price Quote

We are engaged in the manufacturing, supplying, and exporting of 2 pin power cord, which is assembled in accordance with industry norms. Our 2 pin power cord is available in flexible p.v.c. Molding and with excellent insulation. Further, as per the clients specification, we provide them customized 2 pin power cord at the most affordable prices. highlights robust constructiondimensional accuracyhigh performanceindustry standardseconomical prices

Plastic Disposable Spoon Mould

3 Per Piece

1 Piece (MOQ)

Bhagyalaxmi Electroplast Pvt Ltd is also in possession of well equipped with latest machines for production of various types of Plastic Molded components which are exported to UK, USA, and W.Germany etc… All these equipments are designed with utmost core & precision and hence deliver optimum performance. Our clients are well contended with our range of products and hence have referred us to other organizations as well. We make sure to hold high reputation of the organization admits our counterparts

Best Deals from Industrial Molds

Plastic Moulds

Get Price Quote

We provide sturdy & durable Plastic Moulds having high accuracy. We are tagged as a prominent name for supplying Plastic Moulds in the national market. We assure you to deliver goods to the desired place, as we have strong distribution network and shipping facilities.

Cube Mould

800 Per Piece

10 Piece (MOQ)

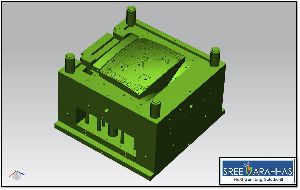

Plastic Designs Moulds

Get Price Quote

sree varahhas team has experience of providing valuable services to several plastic product manufacturers in mould design area. The range of components includes: automotive exterior body parts instrument panels lighting system components appliances television music system tape recorder refrigerator lighting housings holders fmcg perfume bottles & caps shampoo bottles tooth brushes sree varahhas team has worked with the clients in manufacturing single-cavity and multi-cavity plastic moulds for the following processes: injection moulding blow moulding thermo forming our team understands the manufacturing requirements of various dies such as: parting line design undercut verification side core design electrode planning our team of experts can work with the customer in a seamless manner to produce the moulds of high quality in a short time-frame.

Plastic Injection Mould

Get Price Quote

Plastic Syringes manufacturing is going to start pending October 2016. Buyers interested to get orders executed immediately please excuse. We are looking for the following requirements in customers (i) who make bulk orders (ii) who make orders periodically (weekly, monthly, quarterly,....) Price depending on quantity and that given in quote will be final and binding to the order.

Plastic Injection Moulds

Get Price Quote

The company is a major Manufacturer and Supplier of Plastic Injection Moulds in Hyderabad. The company is involved in the production and supply of a wide range of Plastic Injection Moulds and the quality is widely appreciated. The Plastic Injection Moulds are known for their durability as well as high degree of precision.

Plastic Injection Moulds

Get Price Quote

Our company is counted among well-reckoned Manufacturers and Suppliers of precision-engineered Plastic Injection Moulds. Renowned for its compact designs, our Plastic Injection Moulds are of unparalleled standards. Buyers can get the plant from us at market leading prices. As it is made from reliable materials, we guarantee our Plastic Injection Moulds are corrosion resistant structurally stable and durable.

Injection Mould

Get Price Quote

We are manufacturers for injection moulds, and supply of moulded plastic components,extrusion die and aluminum extrusion components.

Sublimation Moulds and Dummies

Get Price Quote

When we are dealing with the inputs of the sublimation business, often a debated input is of Sublimation Moulds and Dummies for phone cases. Many suppliers say that dummies is not necessary in the production of appropriate and correct phone cases. We, being in this field for several years now, we believe that moulds and dummies are equally important for the production of right phone cases. Moulds When you are into the sublimation business, one thing that you would encounter on a daily basis is the heat of the heat press machine. When we are making anything using the heat press machine, in the 3D Sublimation business, then we tend to put the item to be printed, with the printed sublimation paper into the sublimation machine. The sublimation machine usually works at 180 degrees to 200 degrees. The items tend to go through this heat everyday, every time. Since our blanks are either made of ceramic or of plastic, hence the blanks become hot and fragile due to high temperature. Now, due to the high temperature, the plastic or even metallic phone cases tend to lose their shapes. A distorted mobile case or cover wont fit any phone and hence will be of no use either to the producer or to the buyer. Hence, for the rescue, we have moulds and dummies of all the phone cases and covers. Moulds are pre shaped phone cases and covers that dont melt or lose their shape even at the high temperature. Hence when you are printing the phone case, then you can wear the phone case over the mould. This would lead to not disturbing the shape of the phone case or cover. Dummies On the other hand, dummies are models of phone. These dummies dont have the battery or the machine of the phone, rather its just the hardware of the phone. When you are done with the printing then you can use the dummies to check whether the phone case or the covers are in the correct shape or not. When you will use the dummy of any phone, to check the printed phone cover or case, then you will be sure that whether the case/cover will actually fit perfectly the customer’s phone or not.

Insert Moulded Parts

Get Price Quote

PVC CUBE MOULD

850 Per Piece

1 Piece (MOQ)

Plastic Bottle Blow Mould

Get Price Quote

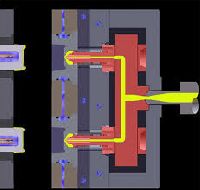

Injection Moulding Dies

Get Price Quote

The company is a prominent Manufacturer, Exporter & Supplier of Injection Moulding Dies. The Injection Moulding Dies, offered by the company, are known for their flawless operations and long life. The company is offering a quality range of the Injection Moulding Dies at the market leading prices across the global markets. Working Plastic Granules are poured into the hopper and are heated up in the plasticing cylinder. The hydraulic or pneumatic ram forces the molten plastic out through the injection nozzle. (The exit to the hopper is closed off so that the molten plastic cannot escape back up into the hopper). The Molten plastic enters the injection molding die under great pressure so that it fills every part of the die cavity. (It is important that the die is preheated so that the plastic does not solidify on contact with the cold steel and block the sprue hole)The die is clamped together under considerable pressure so that the molten plastic cannot seep out through the joins. Guide pins ensure that the die parts line up accurately to give a good quality product. If the die pins wear and become loose the two halves of the product will be misaligned. The internal surface of the mould is finished to a high standard � either polished or textured. Advantages of Injection Molding Injection molded products are usually of high qualityFinish of the mould can be polished or texturedInjection molding can produce product very quickly especially if the machines are automatedA wide range of thermoplastics can be injected successfullyGenerates lots of cheap/disposable plastic products

Cast Iron Ingot Moulds

Get Price Quote

We specialize in manufacturing high quality Ingot Moulds using induction furnace route as well as cupola furnace route. They are not only superior in quality but also offer higher life to your products.

AAC Mould Boxes

16,500 Per Piece

Injection Moulds - 02

Get Price Quote

We are looked upon as one of the most preeminent Injection Moulds suppliers in india. Customers from every nook and corner of india are placing huge and repeated orders for the thermoplastic injection moulds due to the unmatched quality and inexplicable performance exhibited in manufacturing of various bottle tops, sink plugs, children's toys, containers, model kits, disposable razors and parts of cameras. Moreover, the injection moulds are also used in the manufacturing of the larger items like dustbins and milk crates. Customers are also eased with the availability of the custom injection moulds as per the special requisites provided.

Automobile Mould

300,000 Per Piece

We are the leading manufacturers, exporters and supplier of this products.

hot runner injection mold

Get Price Quote

hot runner injection mold With its focus on the molds for rigid packaging applications used by FMCG sector,Amritha works closely with packaging development teams of several multinationals and plays a key role in value adding to the projects With a very supportive and motivated team,Amritha has several times delighted the customers by breaking barriers in mold completion time lines and by holding hands from the initiation of projects till the product is proven on the assembly lines.

Thermocol Moulded Packaging box

20 Per Piece

Industrial Molds

Get Price Quote

Industrial molds with unique requirements can be 3D printed to improve their performance and to reduce production time and costs. Get high quality industrial molds at Build Protos. Features: • Customized and user friendly • Excellent in performance • Highly appreciated quality of products • Best option if you have a unique requirement • Cost effective and saves a lot of production time • Quality products can be delivered within dead lines • Risk free, flawless products

industrial rubber moulds

25 - 10,000 Per Square Inch

Good Quality with low price competitive price. Suitable for Industrial use and available all sizes of rubber moulds.

Die Casting Mould

Get Price Quote

Die Casting Mould, CNC Machined Component, Forged Components, Die Casting

Injection Molding Die

10,000 Per Piece

10 Piece(s) (MOQ)

Injection Molded Plastics

Get Price Quote

Injection Molded Plastics, Bottle Caps, Plastic Bottle Caps

Die Casting Molds

Get Price Quote

Die Casting Molds, Plastic Molds, Plastics Components, Precision Tools

Unconfined Compression test mould

Get Price Quote

Unconfined Compression test mould, compacting factor apparatus

Rubber Molds

Get Price Quote

Rubber Molds, die machine, Milling Machine, Surface Grinding Machine

grid casting molds

Get Price Quote

grid casting molds, Hydraulic Cylinders, Hydraulic Power Packs, Jigs

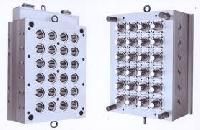

multi cavity molds

Get Price Quote

multi cavity molds, Isostatic Punches, Machine Tools, Magnet, mould