Plastic Injection Mould

Get Price Quote

Plastic Syringes manufacturing is going to start pending October 2016. Buyers interested to get orders executed immediately please excuse. We are looking for the following requirements in customers (i) who make bulk orders (ii) who make orders periodically (weekly, monthly, quarterly,....) Price depending on quantity and that given in quote will be final and binding to the order.

Plastic Injection Moulds

Get Price Quote

The company is a major Manufacturer and Supplier of Plastic Injection Moulds in Hyderabad. The company is involved in the production and supply of a wide range of Plastic Injection Moulds and the quality is widely appreciated. The Plastic Injection Moulds are known for their durability as well as high degree of precision.

Best Deals from Injection Moulds

Injection Mould

Get Price Quote

We are manufacturers for injection moulds, and supply of moulded plastic components,extrusion die and aluminum extrusion components.

Plastic Injection Molding

Get Price Quote

Our plastic injection molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock more than 100 different thermoplastic resins.Common Applications Low-volume production Bridge tooling Pilot runs Functional prototyping How Does Plastic Injection Molding Work?The thermoplastic injection molding process at BEPL is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. It allows our molders to monitor fill pressure, cosmetic concerns, and the basic quality of the parts.Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold’s runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

Two Pin Power Cord

Get Price Quote

We are engaged in the manufacturing, supplying, and exporting of 2 pin power cord, which is assembled in accordance with industry norms. Our 2 pin power cord is available in flexible p.v.c. Molding and with excellent insulation. Further, as per the clients specification, we provide them customized 2 pin power cord at the most affordable prices. highlights robust constructiondimensional accuracyhigh performanceindustry standardseconomical prices

Plastic Injection Moulds

Get Price Quote

Our company is counted among well-reckoned Manufacturers and Suppliers of precision-engineered Plastic Injection Moulds. Renowned for its compact designs, our Plastic Injection Moulds are of unparalleled standards. Buyers can get the plant from us at market leading prices. As it is made from reliable materials, we guarantee our Plastic Injection Moulds are corrosion resistant structurally stable and durable.

Injection Moulds - 04

Get Price Quote

We are looked upon as one of the most preeminent Injection Moulds suppliers in india. Customers from every nook and corner of india are placing huge and repeated orders for the thermoplastic injection moulds due to the unmatched quality and inexplicable performance exhibited in manufacturing of various bottle tops, sink plugs, children's toys, containers, model kits, disposable razors and parts of cameras. Moreover, the injection moulds are also used in the manufacturing of the larger items like dustbins and milk crates. Customers are also eased with the availability of the custom injection moulds as per the special requisites provided.

PLASTIC BOTTLE CAP INJECTION MOULD

1,500,000 Per unit

Plastic Injection Moulding

10 Per Piece

Injection Moulding Dies

Get Price Quote

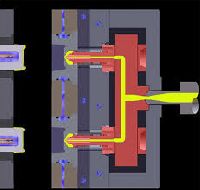

The company is a prominent Manufacturer, Exporter & Supplier of Injection Moulding Dies. The Injection Moulding Dies, offered by the company, are known for their flawless operations and long life. The company is offering a quality range of the Injection Moulding Dies at the market leading prices across the global markets. Working Plastic Granules are poured into the hopper and are heated up in the plasticing cylinder. The hydraulic or pneumatic ram forces the molten plastic out through the injection nozzle. (The exit to the hopper is closed off so that the molten plastic cannot escape back up into the hopper). The Molten plastic enters the injection molding die under great pressure so that it fills every part of the die cavity. (It is important that the die is preheated so that the plastic does not solidify on contact with the cold steel and block the sprue hole)The die is clamped together under considerable pressure so that the molten plastic cannot seep out through the joins. Guide pins ensure that the die parts line up accurately to give a good quality product. If the die pins wear and become loose the two halves of the product will be misaligned. The internal surface of the mould is finished to a high standard ΓΆ€“ either polished or textured. Advantages of Injection Molding Injection molded products are usually of high qualityFinish of the mould can be polished or texturedInjection molding can produce product very quickly especially if the machines are automatedA wide range of thermoplastics can be injected successfullyGenerates lots of cheap/disposable plastic products

hot runner injection mold

Get Price Quote

hot runner injection mold With its focus on the molds for rigid packaging applications used by FMCG sector,Amritha works closely with packaging development teams of several multinationals and plays a key role in value adding to the projects With a very supportive and motivated team,Amritha has several times delighted the customers by breaking barriers in mold completion time lines and by holding hands from the initiation of projects till the product is proven on the assembly lines.

Injection Moulding

Get Price Quote

Injection Moulding, Forged Components, Die Casting, Plastic Moulds

Injection Molding Die

10,000 Per Piece

10 Piece(s) (MOQ)

Injection Molded Plastics

Get Price Quote

Injection Molded Plastics, Bottle Caps, Plastic Bottle Caps

Precision Injection Mold

Get Price Quote

Precision Injection Mold, plastic injections, rubber moulding

Injection Molding

Get Price Quote

We offer injection molding is the technique of injecting molten plastic into a cold mold and forming a part. A schematic of the main elements of a molding machine are shown in figure. It consists of a hopper that holds the raw plastic pellets.

Plastic Injection Moulding

Get Price Quote

Plastic Injection Moulding, Blow Moulding, jig fixture, Jigs

Injection Molded Plastics

Get Price Quote

Injection Molded Plastics, Plastic Matka- for Ice Cream Packing

Injection Moulding Dies

Get Price Quote

Injection Moulding Dies, hd plastic granules, Injection Moulded Components

Injection Moulds

Get Price Quote

Injection Moulds, precision die casting, Dies, Press Tools

Clip Mould

Get Price Quote

Moulds, box mould

Injection Moulding

Get Price Quote

Injection Moulding, polypropylene compounding, table fan blades

Plastic Injection Moulds

Get Price Quote

Plastic Injection Moulds, rubber insulator moulds, CNC Machining Components

Plastic Injection Molding

Get Price Quote

Plastic Injection Molding, Plastic Blow Molds, Pet Bottles Molds, Dies

Injection Moulding Packaging Container

Get Price Quote

Injection Moulding Packaging Container

presses injection moulding

Get Price Quote

presses injection moulding, Plastic Moulding Machine, rubber moulding

Plastic Injection Molds

Get Price Quote

Plastic Injection Molds, Engineering Component, Jigs, Pet Bottles

plastic injection moldings

Get Price Quote

plastic injection moldings, plastic products ice cream cups, pvc shimpads

Plastic Injection Moulds

Get Price Quote

Plastic Injection Moulds, Die Casting Moulds, Plastic Moulded Goods

Plastic Injection Moulding

Get Price Quote

Plastic Injection Moulding, Crates