Top Discharge Centrifuge

The Manual Top Discharge centrifuge is the basic model of the centrifuge where the filtered cake is manually scooped out by the operator. This centrifuge is the most commonly used type and is also the most economical. Sizes Available: Starting from 12” Dia. up to 60” Diameter. Materials of Construction: SS 316, SS 304, SS904L, Hastelloy & Titanium Coating: Halar (ECTFE), Teflon (PFA), Rubber Lining, FRP Lining Manual Top Discharge Centrifuges are available in the following Designs 1. Partial Lid Opening: In this model the lid of the centrifuge only a portion of the top cover of the centrifuge is opened to scoop out the cake. For complete cleaning of the basket and inner parts of the centrifuge the monitor casing of the centrifuge has to be opened. 2. Full Lid Open: In this variant the top lid of the centrifuge has a large diameter that equals the diameter of the monitor casing. This gives better access to basket inside and outer periphery (except bottom) and full access to the top cover. 3. Full Body Opening: In this model the entire top cover of the centrifuge is accessible for cleaning and visual inspection. This is an ideal model for applications involving product changeovers and special cleaning needs. The basket bottom and the Mother Liquor Drain platform can be visually seen in this model. This model is often called cGMP or sanitary model. 4. Full Lid Opening and Full Body opening: In this model both the lid and the Monitor Casing can be opened out for cleaning. In case it is only required to unload the product the top lid can be opened and the cake can be discharged. In case it is necessary to inspect the basket or other parts of the centrifuge the entire monitor casing can be opened. The Lid opening options are: Spring Operated Pneumatically operated or Hydraulically operated systems. Optional Extras: Nitrogen Blanketing, Vibration Limiter, RPM Sensor with Indicator, Zero Speed Interlock, Cleaning in Place (CIP), Cake thickness sensor, Pneumatic Lid Opening System, Hydraulic Lid or Body opening systems

...more

Pharmaceutical Peeler Centrifuge

In this machine process system is separated from service system. All maintenance activities will be carried out in service area which can locate outside the clean room by installing the machine through the wall. The horizontal peeler centrifuge is known for its many advantages from its horizontal rotation arrangement of the basket. By arranging the axis horizontally, advantages in washing capability, uniform solid size distribution for better solid output quality. The feeding action in centrifuge is effective as the feeds are fed perpendicularly to gravity and centrifugal force spreads out the solids evenly on basket inner surface. Also the casing of the centrifuge can be fully opened which allows easy access to inside of rotating basket. This also means the operator can get access to internal components including filter cloth which required replacement. And its high discharge speed reduces time taken to accelerate and braking for rotation for high capacity, so does power consumption, wear and tear. This short cycle time is particularly beneficial for short cycle, fast-filtering requirements for certain processes. This means these centrifuges provide higher centrifugal forces than vertical centrifuges, and increases performances and flexibility. Due to continuous discharge of filtered liquid through perforated inner surface of rotating basket, the pressure drop, main driving force of filtration is increased across the solid cake and filter medium; as a result, the filtration rate can be boosted. Moreover, high rotational speed results high rotational force which allows lowering residual cake moisture effectively, so does the washing liquid and washing results. Because of effective washing, drying processes that yield high purity of output. In this model the cake is filtered in the same manner as the vertical models but the cake discharge is achieved by means of a scraper knife that plows into the cake. At this point the basket is in rotation at a preset low speed and the cake is peeled off the Basket surface and discharged through the discharge chute which was mounted on outer casing. The filter bags in these centrifuges are held in place by Tensioned Rings or by screws and the bags may also have backing cloth or mesh to impart structural rigidity to the bag so that the bag does not distort of collapse while the knife is being engaged. The small gap between the scraper and the Basket Shell results in a thin layer of cake remaining inside the Basket. This layer is known as the Residual Heel. A Blow Off arrangement is provided to remove this Heel. Typically this is achieved by a blast of Air/ Nitrogen from specially arranged Air Delivery nozzles mounted on a pipe. The pipe is aligned with the basket perforations so that when the blast of Air is sent in to the pipe it travels through the Basket perforations and dislodges the Residual Heel. The action of the scraper knife is by means of a Hydraulic Cylinder which is powered by a Hydraulic Power Pack. The Scraper knife has mechanical limits so that the knife does not accidentally come in contact with the Basket Shell.

...more

Manual Top Discharge Centrifuge

Top Discharge Centrifuge The Manual Top Discharge centrifuge is the basic model of the centrifuge where the filtered cake is manually scooped out by the operator. This centrifuge is the most commonly used type and is also the most economical. Sizes Available: Starting from 12” Dia. up to 60” Diameter. Materials of Construction: SS 316, SS 304, SS904L, Hastelloy & Titanium Coating: Halar (ECTFE), Teflon (PFA), Rubber Lining, FRP Lining Manual Top Discharge Centrifuges are available in the following Designs 1. Partial Lid Opening: In this model the lid of the centrifuge only a portion of the top cover of the centrifuge is opened to scoop out the cake. For complete cleaning of the basket and inner parts of the centrifuge the monitor casing of the centrifuge has to be opened. 2. Full Lid Open: In this variant the top lid of the centrifuge has a large diameter that equals the diameter of the monitor casing. This gives better access to basket inside and outer periphery (except bottom) and full access to the top cover.

...more

Laboratory Centrifuges

Over the years we have studied the procedures followed in R&D labs and have found that a convenient centrifugation method was not available. To fill this gap we developed a small centrifuge that is portable and easy to operate. The batch sizes range from 5 to 10 liters. These models are ideal for Kilo Lab applications besides regular R&D Labs. They are manufactured to be deployed in GMP environments. Not only Kilo Lab applications, Pilot plant operations are also becoming more important as several high value products are manufactured in a small scale. These models have batch volumes ranging between 28 Liters to 45 Liters and are available in fixed and portable formats. As these products must be produced in a similar GMP environment and should use equipment similar to those that would be used when the volume of production increases and when the production is moved into a commercial scale plant. These Centrifuges usually manual top discharge machines and are used for small batches in plant and R&D laboratory experiments. These machines are not required heavy foundations can be placed on trolleys to move easily to specified operational zones. These machines can be supplied with or without trolley depends on customers requirement.

...more

Inertization Systems

Nitrogen Blanketing is done to reduce hazards while centrifuging volatile flammable solvents. The system consists of a series of valves, pressure switches and solenoid valves that work in tandem to ensure safe operations. The centrifuges intended for Inertization are in vapour tight construction and are provided with inlet and outlet ports for the purging gas. Inertization can be carried out for both Monitor Casing as well as Bearing Housing These systems can be operated in semi-automatic or automatic mode. In case the Nitrogen Blanketing system is being automated a PLC (Stand alone or main Centrifuge PLC) is used to control the program. In special cases an online oxygen analyzer is incorporated in the system to restrict oxygen levels within safe limits.

...more

Horizontal Peeler Centrifuge

4,500,000 - 7,500,000 Per Piece

Pharma Peeler Centrifuges In this machine process system is separated from service system. All maintenance activities will be carried out in service area which can locate outside the clean room by installing the machine through the wall. The horizontal peeler centrifuge is known for its many advantages from its horizontal rotation arrangement of the basket. By arranging the axis horizontally, advantages in washing capability, uniform solid size distribution for better solid output quality. The feeding action in centrifuge is effective as the feeds are fed perpendicularly to gravity and centrifugal force spreads out the solids evenly on basket inner surface. Also the casing of the centrifuge can be fully opened which allows easy access to inside of rotating basket. This also means the operator can get access to internal components including filter cloth which required replacement. And its high discharge speed reduces time taken to accelerate and braking for rotation for high capacity, so does power consumption, wear and tear. This short cycle time is particularly beneficial for short cycle, fast-filtering requirements for certain processes. This means these centrifuges provide higher centrifugal forces than vertical centrifuges, and increases performances and flexibility. Due to continuous discharge of filtered liquid through perforated inner surface of rotating basket, the pressure drop, main driving force of filtration is increased across the solid cake and filter medium; as a result, the filtration rate can be boosted. Moreover, high rotational speed results high rotational force which allows lowering residual cake moisture effectively, so does the washing liquid and washing results. Because of effective washing, drying processes that yield high purity of output.

Color : Grey

Condition : New

Automatic Grade : Automatic

Type : Horizontal

...more

Chemical Peeler Centrifuges

The horizontal chemical peeler centrifuges were specially designed to meet the filtration requirements of the chemical and fine chemical industry. The Chemical peeler centrifuge is known for its many advantages from its horizontal rotation arrangement of the basket. By arranging the axis horizontally, advantages in washing capability, uniform solid size distribution for better solid output quality. The feeding action in centrifuge is effective as the feeds are fed perpendicularly to gravity and centrifugal force spreads out the solids evenly on basket inner surface. In this centrifuge the lid of the centrifuge can be fully opened which allows easy access to inside of rotating basket. This also means the operator can get access to internal components including filter cloth which required replacement. And its high discharge speed reduces time taken to accelerate and braking for rotation for high capacity, so does power consumption, wear and tear. This short cycle time is particularly beneficial for short cycle, fast-filtering requirements for certain processes. This means these centrifuges provide higher centrifugal forces than vertical centrifuges, and increases performances and flexibility. Due to continuous discharge of filtered liquid through perforated inner surface of rotating basket, the pressure drop, main driving force of filtration is increased across the solid cake and filter medium; as a result, the filtration rate can be boosted. Moreover, high rotational speed results high rotational force which allows lowering residual cake moisture effectively, so does the washing liquid and washing results. Because of effective washing, drying processes that yield high purity of output. In this model the cake is filtered in the same manner as the vertical models but the cake discharge is achieved by means of a scraper knife that plows into the cake. At this point the basket is in rotation at a preset low speed and the cake is peeled off the Basket surface and discharged through the discharge chute or Screw conveyor which was mounted on outer casing. The filter bags in these centrifuges are held in place by Tension-ed Rings or by screws and the bags may also have backing cloth or mesh to impart structural rigidity to the bag so that the bag does not distort of collapse while the knife is being engaged. The small gap between the scraper and the Basket Shell results in a thin layer of cake remaining inside the Basket. This layer is known as the Residual Heel. A Blow Off arrangement is provided to remove this Heel. Typically this is achieved by a blast of Air/ Nitrogen from specially arranged Air Delivery nozzles mounted on a pipe. The pipe is aligned with the basket perforations so that when the blast of Air is sent in to the pipe it travels through the Basket perforations and dislodges the Residual Heel. The action of the scraper knife is by means of a Hydraulic Cylinder which is powered by a Hydraulic Power Pack. The Scraper knife has mechanical limits so that the knife does not accidentally come in contact with the Basket Shell.

...more

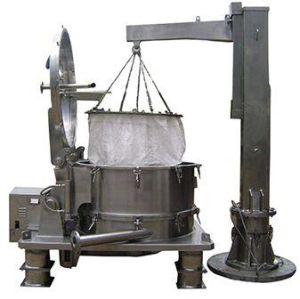

Lifting Bag Centrifuge Machine

This device meets with cGMP and dispenses with the need for an overhead hoist. This device was made of Carbon Steel and clad with Stainless Steel and can be placed next to the machine inside GMP area. With this we can eliminate chain & pulley mechanisms for lifting & prevents product contamination.

...more

Bag Lifting Centrifuge

Bag Lifting Centrifuge is an improvement over the Manual Top Discharge centrifuge and is now a very popular model. In this model the Filter Bag is fastened to the Basket top plate. The Basket Top plate is in turn locked onto the basket shell. When the filtration is completed the Plate is removed by unlocking the plate from the basket shell and pulled out using a hoisting arrangement. The filter bag containing the product comes out of the centrifuge. The product is then moved out to a suitable location and unloaded. The Main Advantage of this machine is that the unloading time is reduced considerably and also has less manual intervention when compared with a manual Top Discharge centrifuge. High production rates can be achieved with this machine. In this machine the Basket Shell is slightly tapered to facilitate easy pull out of the filter bag after the process is completed. Sizes Available: Starting from 24” Dia. up to 60” Diameter. Materials of Construction: SS 316, SS 304, SS904L, Hastelloy & Titanium Coating: Halar (ECTFE), Teflon (PFA), Rubber Lining, FRP Lining Bag Lifting Centrifuges are available in the following Designs 1. Full Lid Open: In this variant the top lid of the centrifuge has a large diameter that equals the diameter of the monitor casing. This gives better access to basket inside and outer periphery (except bottom) and full access to the top cover. 2. Full Body Opening : In this model the entire top cover of the centrifuge is accessible for cleaning and visual inspection. This is an ideal model for applications involving product changeovers and special cleaning needs. The basket bottom and the Mother Liquor Drain platform can be visually seen in this model. This model is often called cGMP or sanitary model. The Lid is opened by using Spring Operated, Pneumatically operated or Hydraulically operated systems. Optional Extras: Nitrogen Blanketing, Vibration Limiter, RPM Sensor with Indicator, Zero Speed Interlock, Cleaning in Place (CIP), Cake thickness sensor, Pneumatic Lid Opening System, Hydraulic Lid or Body opening systems, and Bag Lifting Device.

...moreBe first to Rate

Rate ThisOpening Hours