Temperature Gauge

Get Price Quote

Digital Torque Gauges

Get Price Quote

Digital torque gauges, High pressure and high flow DC-motor piston pump, Equipped with selectable control feature and self protecting feature, Adjustable PWM, Over current protection Overload protection, Protection against crossing wires, Alarm output terminal and fuse for malfunction.

Best Deals from Measurement Gauge

Digital Differential Pressure Gauge Model

Get Price Quote

Digital Differential Pressure Gauges are digital readout monitors intended for estimating the room pressure inside Pharma clean rooms, isolation rooms&hospital operation theaters. This advanced gauge comes with 0.5% accuracy, capable of nonstop measurement.Features Include: Unit change at the Press of a Key Between mm.W.C. and Pascal’s, Integrated Buzzer Alarm for Set Point Violation, Offset Provision to Meet Audit Requirements, Analog 4-20ma Output, 30 mm. Profundity for Clean Room Modular Wall Fitment and RS 485 Modbus Communication For BMS/SCADA/PLC Integration.

Tipping Bucket Rain Gauge

4,500 - 5,000 Per Piece

DIGITAL DIAL GAUGE

3,800 Per Piece

10 Piece (MOQ)

Pressure Gauges

Get Price Quote

Water Level Indicator for Tanks

Get Price Quote

Automatic water level controller with indications

Sheave Gauges

Get Price Quote

Sheave Gauges are, now, a solution to your worry on worn sheaves and damaged belts. A comprehensive tool to maintain the efficiency of the belt drive system, yourself.

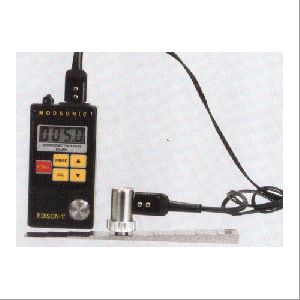

Ultrasonic Thickness Gauges

31,700 - 75,450 Per Piece

1 Piece(s) (MOQ)

Basic model in EDISON Series Simple in operation Large 4 digit LCD Display Operates on two AA size batteries One step calibration Accurate, Reliable and Robust Accuracy of ±1 mm Full range of probes for all applications Detachable Probe Cable Option of EL back light for indoor / dark areas Sealed touch keypad Technical Specification: Applicable Material: All homogeneous materials which allow transmission of Ultrasonic energy through it like most of metals, hard plastics, glass, ceramics etc. Measuring Range: 1mm to 300mm (Specified range depends on test material, transducer, surface and temperature.) Probe: Dual crystal (Transmitter Receiver) type. Key Pad: Sealed tactile type Velocity: 1000 m/s to 9999 m/s. Display: LCD type. It displays Thickness, Velocity, Battery check, Coupling check, and stored readings with IDs. Resolution: 0.1 mm(0.01mm in EDISON-1P) Accuracy: 0.1mm (up to 60mm) {with standard 0.5% (above 60 mm) probe DT 201} V- path Correction: Built-in for better accuracy. Calibration: One step calibration.(for steel). Battery: 2 Penlite Dry Cells (AA) or NiCd. Operating time: 18 to 20 hours.(with alkaline batteries). Low Battery: Indication by Blinking of LCD. Auto Power off 3 minutes after switching on/ last reading Size mm: 125(H) x 65(W) x 30(D). Weight: 225 Grams (With batteries)

Level Indicator

Get Price Quote

Based in Hyderabad, Telangana we are one of the most-reliable manufacturer and supplier of Level Indicator. We offer Level Indicators in wide range of specifications and models to satisfy the client requirement. Manufactured using raw materials sourced from best-in-industry vendors, our Level Indicators come with an internationally acclaimed quality. These Level Indicators have applications in Oil filled Power Transformers and Oil filled Tanks.

Compact Sealed Gauge

Get Price Quote

Our Compact Sealed Gauge is designed by the experienced engineers in compliance with the specific requirements of the clients. Owning a huge popularity among the clients, our Compact Sealed Gauge provides reliable reading in hardcore industrial applications. SpecificationsDial : 100 & 150 mmMounting : BottomAcessory : Serface plateApplications : Compressed Air, Purge Gas, SWAS etc.

Water Level Indicator

4,500 - 6,500 Per one

Established in the year 2007, Sunshine Electronics in Kphb Colony, Hyderabad is a top player in the category Automatic Water Level Controller Distributors in the Hyderabad. This well-known establishment acts as a one-stop destination servicing customers both local and from other parts of Hyderabad. Over the course of its journey, this business has established a firm foothold in it’s industry. The belief that customer satisfaction is as important as their products and services, have helped this establishment garner a vast base of customers, which continues to grow by the day. This business employs individuals that are dedicated towards their respective roles and put in a lot of effort to achieve the common vision and larger goals of the company. In the near future, this business aims to expand its line of products and services and cater to a larger client base. In Hyderabad, this establishment occupies a prominent location in Kphb Colony. It is an effortless task in commuting to this establishment as there are various modes of transport readily available. It is at Road No 2, Above Binnys Dental Hospital, Beside Lane to Priyanka Showroom, which makes it easy for first-time visitors in locating this establishment. It is known to provide top service in the following categories: Water Purifier Repair & Services, Ro Water Purifier Repair & Services, Ro Water Purifier Dealers, Water Level Controller Dealers, Automatic Water Level Controller Dealers, Water Level Indicator Dealers, Water Level Controller Manufacturers, Automatic Water Level Controller Distributors.

Oil Level Indicator

Get Price Quote

Oil level gauge is used in distribution transformers can be supplied with any of the below indicators h m lo 90 30 -5 degress nor low.

Temperature Gauges

Get Price Quote

This series of thermometers is designed for installation in pipes, tanks, plants and machinery. Stem and case are made of stainless steel. To allow fitting to the process, different insertion lengths and process connections are available. Through the high ingress protection of the thermometer (IP 65) and its liquid damping, operation under high vibration conditions is possible. Special Features Application ranges from -70 ...+600 °C 6 different connection designs selectable Case and stem material stainless steel Applications Chemical, petrochemical industry Power engineering Machine buildung and general plant construction Food industry

electronic gauges

Get Price Quote

Restricting to the pre-defined quality parameters, we make sure that the offered array of products is as per the stated norms. In order to ensure zero damage during transit, we have adopted modern facility for meticulously packaging our offerings. And, we also ensure that the used material is of high quality.

Digital Differential Pressure Gauge

Get Price Quote

We are offering digital differential pressure gauge. Mounts in industry standard holes 1.6″ panel depth universal power 16 -265 vacvdc (2) 8amp spdt relays accuracy 1% (better available) large 0.5″ led display led process arch measures flow velocity 15 selectable units optional 4-20ma output filter status duct static pressure clean room pressure building pressure fan blower pressure paint booths dust collectors glove box pressure bubbler systems laminar flow hoods cabinet purging

air gauge

Get Price Quote

Every gauge carries a calibration certificate giving actual values,Module 1A, Module 2A giving the most economical solution to your inspection needs on shop floor,High pressure system: high speed of response and self cleaning of gauging area ensures accurate reading of size, taper and ovality at a time Non-contact gauging: long life due to minimal frictional wear Two setting Masters: ensures correct magnification of reading at all times System pressure check gauge: provides a constant check on the system pressure i.e. 3 bars (45 psi) regulated by a high precision regulator built into the unit Minimum line pressure required 4.5 bars (67 psi) Air consumption 46 LPM For diameter 6 mm and above Module-1A air gauge unit is to be used For diameter below 6 mm Module-2A air gauge unit is to be used

Digital Differential Pressure Indicator

5,900 Per Piece

Ace AI-DP1 Digital Differential Pressure Indicator is digital readout differential pressure indicator designed for measuring the room pressure inside Pharma clean rooms, Hospital operation theaters & Isolation rooms. Salient Features include Unit Conversion at the press of a key between mm.W.C.& Pascals integrated buzzer alarm for set point violation, Offset provision to meet Audit requirements, analog 4-20mA Output, 42 mm depth for Clean Room Modular Wall Fitment & RS 485 Modbus communication for BMS/SCADA/PLC integration.

Air Cooling Ring

Get Price Quote

Coating Thickness Gauge

Get Price Quote

Measures thickness of coatings on metal, Range : 0 - 1.80 mm

Tipping Bucket Rain Gauge

Get Price Quote

The Tipping Bucket performs a wide range of rainfall measurements. The receiver is 200 mm in diameter. The Tipping Bucket measures each 0.2, 0.5, 1mm or 0.01 inch of rainfall. It could also include a siphon (optional) that allows rain to flow at a steady rate to the tipping bucket mechanism regardless of rainfall intensity. This system allows control of the “flow rate” of accumulated precipitation. This metering geometry assures higher levels in both accuracy and repeatability during periods of extremely heavy rainfall. Tipping bucket gauges operate by capturing a small volume of water in one of two small buckets as shown in Figure below. Once the rain is captured, the bucket tips and empties. The occurrence of this “tip” is recorded, and precipitation volumes and rates are transmitted as the number of tips and the rate at which they occurred. Tipping bucket rain gauges tend to underestimate precipitation during periods of intense rainfall and in case of frozen precipitation. All gauges tend to underestimate in high wind. But compared to weighing gauges, tipping bucket gauges are less expensive and demand significantly less maintenance. Our Tipping Bucket Rain Gauge is the only one Stainless Steel Tipping Bucket Rain Gauge for Cylinder, Base, Tipping Bucket, all metal.

Diaphragm Gauges

Get Price Quote

We manufacture high efficiency diaphragm gauges having a dial size of 10 mm, 150 mm. These diaphragm gauges are made from aluminium and stainless steel, these gauges are durable and have a longer life. Diaphragm pressure gauges are used to measure gases and liquids. They cover measuring spans from 10 mbar to 40 bar. The measuring element consists of one circular diaphragm clamped between a pair of flanges. The positive or negative pressure acting on these diaphragms causes deformation of the measuring element. The magnitude of the deformation is proportional to the pressure to be measured, and it is coupled to the pointer mechanism.

Electronic Vacuum Gauge

15,000 Per Piece

Temperature Gauges

Get Price Quote

10 Piece(s) (MOQ)

Description : This series of thermometers is designed for installation in pipes, tanks, plants and machinery. Stem and case are made of stainless steel. To allow fitting to the process, different insertion lengths and process connections are available. Through the high ingress protection of the thermometer (IP 65) and its liquid damping, operation under high vibration conditions is possible. Special Features : Application ranges from -70 ...+600 oC 6 different connection designs selectable Case and stem material stainless steel Applications : Chemical, petrochemical industry Power engineering Machine buildung and general plant construction Food industry

Pressur Gages

Get Price Quote

We are offering pressur gages. We are manufacturer of steam boiler/ incinerator/ hot air/water generator/ thermic fluid heater/ autoclave / bio medical waste shredder / burner/boiler & its spares/supplying of synthetic thermic fluid oil/ 8096050053

Screw Gauge

Get Price Quote

We are supplier of this product.

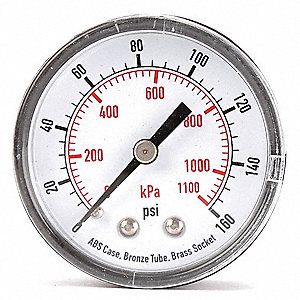

Analog Pressure Gauge

Get Price Quote

Terrameter

Get Price Quote

Water Level indicator (100m – 1000m depth) with counter mechanism is a very handy device to quickly check the level of water in open wells and in borewells. A sensor attached to the end of a cable, wound on a winch is lowered in to the well. over a calibrated wheel attached to the counter mechanism. The moment the sensor touches the water surface, a panel meter on the winch which is on the ground shows full deflection with buzzer sound. The depth to the water level from the ground can be read off in metric scale on the counter.

Tubular Level Indicators

Get Price Quote

Level Gauges are used to determine the levels of fluids like oil and water present in tanks. These are extremely important to industries and other manufacturing industries as these inform about the levels of fluids present in machines and tanks before they go empty. We, at Khemas Engineers manufacture elite quality level gauges that can be used as Tank Level Gauges, Fuel Level Gauges, Water Level gauges and also as mechanical level gauges. The gauges are processed with the best-in-class engineering skills mixed with the excellent quality raw materials and precision equipment machinery. We provide tubular level gauges for low pressures and reflex and transparent level gauges for high pressure. The merits of buying the level gauges from us are- Accurate level gauging Compatible with majority of fluids Tough design Quick installation Easily readable Note:- We are happy to inform you that we have purchased Glasstube Forming machine and testing equipment from TRAC (Transducers and Controls Pvt.Ltd.) which has closed down its production.we are now in a position to supply same meters and spare parts earlier supplied by TRAC.

Digital Coating Thickness Gauge

17,500 Per Piece

1 Piece (MOQ)