vigilance control device

Vigilance Control Device (VCD) is a microcontroller based safety device which will automatically apply penalty brakes in case the driver is incapacitated. Similar operation is available in older locomotives in the form of Deadman’s Lever.

...more

Vehicle Control Systems

We are offering vehicle control systems. A typical vehicle control system comprises microprocessor based vehicle control unit, associated sensors, distribution boxes, contactors, and display unit with keypad. Based on the application, the hardware and configuration of the system varies. Medha’s vehicle control systems are high performance microprocessor based modular systems that provide complete traction and propulsion control of the vehicle with continuous monitoring and extensive fault diagnostics. Major functions include engine control, excitation control, propulsion control, wheel slip control, auxiliary controls, protections, fault diagnostics, data recording and parameter display.

...more

Event Recorder

Event Recorder are available Medha also supplies Test Equipment for these systems and custom speed sensors that work with these Speed Recorders. The event of an accident the recorded data becomes vital for establishing the cause of accident.

...more

electronic interlocking system

Electronic Governor

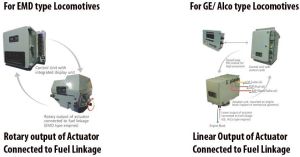

We are offering electronic governor. Electronic governor is a maintenance free alternative to the mechanical governors popularly used for this application. The governor consists of a control unit mounted in the driver cab, and an actuator unit mounted on the engine. The actuator unit can be mounted exactly on the same engine base as mechanical governors. The governor controls the engine speed, based on throttle handle position (popularly known as notch) selected by the driver on the driver desk. Engine rpm is measured from a tachogenerator or speed sensor mounted on the engine. Digital pid control is used to calculate desired fuel rack position dynamically, based on the selected notch on throttle handle and measured engine rpm. A stepper motor drive is used in the actuator unit to control the fuel rack of diesel engine. The governor also controls load on the engine electrically, to limit horsepower at each notch to a pre-set level, through an electrical interface with the excitation system of locomotive. Booster (turbo) air pressure is measured through a pressure sensor mounted in the air manifold. Movement of fuel rack is limited as a function of this pressure to prevent incomplete combustion of fuel, black smoke, excessive engine temperature, fuel wastage etc caused by lack of air to burn the fuel. Lube oil pressure is continuously monitored and engine is shutdown if the lube oil pressure is less than the specified pressure at each notch position. This protects the engine from damage due to malfunction of lube oil pump etc.

...more

diesel locomotive engine

1.Engine (MFI, EFI or CRDI) 2.Alternator (AC) 3.Traction Converter (IGBT Based) 4.Control Panel (Microprocessor Control with electricals) 5.Driver Console (with TFT LCD displays) 6.Hotel Load Converter (HEP) 7.Dynamic Brake Resistor (DBR Grids) 8.Traction Motors (AC) 9.Electronic Governor CRDI (Retrofit) 10.Fuel Level Sensors (Ultrasonic type) 11.Locomotive Remote Monitoring (LRMS).

...more

Block Proving Axle Counters

Medha's BPAC system ensures that the track section is empty before permitting another train in that section, eliminates human error and controls safe movement of trains between stations. No train is permitted if there is any other train, parted train, detached wheels, rail trolley or other rail vehicle in that section. Applicable standards include EN50121, EN50126, EN50128, EN50129, EN50159-1 & 2 Medha’s BPAC’s advantages over conventional systems Standalone system- not dependent on type and make of interlocking Can be used for Single or Double Line block section Very low power consumption Communication compatible for Quad cable, voice channel over OFC or dedicated OFC Withstands adverse environmental conditions Audio-visual intimation and acknowledgement feature for both end stations Automatic functioning without human intervention

...more

Axle Counter

Medha's BPAC system ensures that the track section is empty before permitting another train in that section, eliminates human error and controls safe movement of trains between stations. No train is permitted if there is any other train, parted train, detached wheels, rail trolley or other rail vehicle in that section.

...more

Auxiliary Power Converter

APU is a self-contained system with its own small diesel engine coupled to low capacity compressor and alternator to maintain main reservoir pressure, charge battery, operate driver cabin HVAC system and other small loads as per customer requirement. The main engine is started only when the locomotive is actually required for movement or traction.

...more

energy recorders

inverters fault diagnostic system

micro controller based governor

speed recorders

electrical locomotive auxiliary converter

inverter motors

locomotive control computer

traction converter

Traction Alternators

Traction alternators are designed in association with our joint venture partner traktionssyteme, austria and in compliance with international standards such as iec 60349-1, using state-of-the-art manufacturing facilities at austria or in india. The alternators are produced and tested as per iec60349-1. Class 220 insulation is achieved by adhering to stringent material requirements and very good impregnation system. Traction alternators are designed to withstand harsh railway conditions when installed on locomotives and dmus and to suit any type of traction system.

...more

Remote Monitoring

We offer remote monitoring.vehicle remote monitoring solution is an internet based system connecting all locomotives in the field with centralized locomotive management system through cdma and or gsm network communication. This solution consists of: locomotive and train management system (ltms) a centralized server serves as repository for information received from locomotives through internet. Information includes locomotive location, operational parameters, health status, fuel level data, fault logs and related information, life-time counters and event recorder data. Authorized users can log into ltms to view present and past information, analyze details of locomotive and plan for maintenance. Locomotive remote monitoring system (lrms) lrms is an on-board unit with interface to locomotive computer, gsm andor cdma communication devices and gps receiver. This rugged system sends all locomotive information to ltms at periodic intervals. Lrms can also be used as emergency voice communication device by driver.

...moreBe first to Rate

Rate ThisOpening Hours