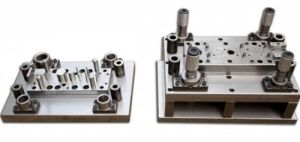

Plastic Injection Mold Designing Services

Get Price Quote

Situated in Shiva Nagar Colony Nagaram, Hyderabad, Telangana (India), Shidha Technologies is involved in providing superior class plastic injection mold designing services to the clients. We have hired a team of adroit plastic injection mold designing experts, who are proficient in melting the solid plastic resin pellets, injecting them into a mold and cooling them back to a solid-state. These experts make use of the most advanced tools & machines to render these services.

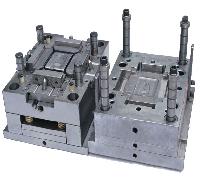

Plastic Injection Moulds

Get Price Quote

Our company is counted among well-reckoned Manufacturers and Suppliers of precision-engineered Plastic Injection Moulds. Renowned for its compact designs, our Plastic Injection Moulds are of unparalleled standards. Buyers can get the plant from us at market leading prices. As it is made from reliable materials, we guarantee our Plastic Injection Moulds are corrosion resistant structurally stable and durable.

Looking for Molding Services Providers

Plastic Injection Moulds

Get Price Quote

The company is a major Manufacturer and Supplier of Plastic Injection Moulds in Hyderabad. The company is involved in the production and supply of a wide range of Plastic Injection Moulds and the quality is widely appreciated. The Plastic Injection Moulds are known for their durability as well as high degree of precision.

Plastic Injection Molding

Get Price Quote

Our plastic injection molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock more than 100 different thermoplastic resins.Common Applications Low-volume production Bridge tooling Pilot runs Functional prototyping How Does Plastic Injection Molding Work?The thermoplastic injection molding process at BEPL is a standard process involving an aluminum mold with no heating or cooling lines running through it, which means cycle times are a bit longer. It allows our molders to monitor fill pressure, cosmetic concerns, and the basic quality of the parts.Resin pellets are loaded into a barrel where they will eventually be melted, compressed, and injected into the mold’s runner system. Hot resin is shot into the mold cavity through the gates and the part is molded. Ejector pins facilitate removal of the part from the mold where it falls into a loading bin. When the run is complete, parts (or the initial sample run) are boxed and shipped shortly thereafter.

Plastic Pouch Packing Machine

Get Price Quote

1 Piece (MOQ)

Plastic Recycling Machine

5,500,000 Per Piece

Plastic Granule Recycling Machine

Get Price Quote

We are instrumental in manufacturing Plastic Granule Recycling Machine. These Plastic Granule Recycling Machines are widely used in different industries. The Plastic Granule Recycling Machine provided by us is fabricated from high-grade raw materials, which are sourced from trusted vendors. Our Plastic Granule Recycling Machines are specially designed by our engineers using technologically advanced machinery and tools. Moreover, the clients can avail these Plastic Granule Recycling Machines in various specifications, at market leading prices. Specifications Machine Size : 100mm8 Inches Manual DieGear BoxHeat Control Panel BoardHeaterOutput per hour : 80kgs to 100kgsPower Consumption : 20HP Sizes Available 100MM110MM120MM

Polyurethane Custom Moulding Service

Get Price Quote

The applications and uses for are as endless as your imagination. We have a wide selection of specialised products for the most demanding applications. We are constantly finding new opportunities in every sector of trade and industry including, transport, commercial, industrial, marine etc. The versatility of open-cast urethane and polyurethane molding produces a wide variety of products for most industries. Applications requiring high abrasion resistance, outstanding tensile and tear strength, noise dampening, chemical resistance, and/or excellent load bearing capability, find that urethane surpasses most other polymers.Expensive metal casting often times can be replaced by lightweight urethane and still maintain or exceed wear characteristics found in their metal counterparts.

Plastic Injection Moulding

10 Per Piece

Ultrasonic Plastic Welding Machine

Get Price Quote

It is hard to imagine how the requirement for quality and reliability of welds, economy and the ecological demand placed on today is production methods could be met without the modern production engineering of ultrasonic welding. Customized solutionsfor complex projects for largecomplex components, systems with multi convertor design (with motherdaughter horns)are available as per specific requirements.multiconverter units are frequently used in the welding of large-area, asymmetrical parts,for example in automobile and apparatus engineering or with toys. The advantage of multiconverter system lies in the construction of small, simple sonotrodes which facilitates to optimise theweld quality along the wholeweld contour due to local targeting. Special purpose machines to meet specific customer requirement is one of our strong points. Building of special purpose machine is artulspeciality. Formany years,we have designed and built systems, which cater to the precise demands of the customer. As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practise. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods. Roop telsonic ultrasonix limited offers wide selection of welding equipment and installation which with respect to generator performance, range of welding force, frequency of operation and possible uses, efficiently satisfies your specific application requirements.

Die Casting Mould

Get Price Quote

Die Casting Mould, CNC Machined Component, Forged Components, Die Casting

Injection Molded Parts

Get Price Quote

Injection Molding

Get Price Quote

We offer injection molding is the technique of injecting molten plastic into a cold mold and forming a part. A schematic of the main elements of a molding machine are shown in figure. It consists of a hopper that holds the raw plastic pellets.

candle making moulds

Get Price Quote

candle making moulds, art material products

Die Casting Moulds

Get Price Quote

Die Casting Moulds, Plastic Injection Moulds, Plastic Moulded Goods

Plastic Injection Moulding

Get Price Quote

Plastic Injection Moulding, Blow Moulding, jig fixture, Jigs

Moulds Service

Get Price Quote

PET Moulds are designed for high performance using Aluminium alloy and stainless steels, which guarantee maximum precision, high stability, and long life. Using sophisticated and very fast systems, we support customers from preform to bottle design, to optimize the functional and aesthetic, demands of the container. Profiled core and cavity cooling channels increase the heat transfer coefficient, resulting in greater efficiency and minimized cycle times. Manufactured to very high standards and optimized for preform production, our moulds have a service life of several years before refurbishing becomes necessary. Mould design makes service and maintenance operations fast and easy. Services we provide : 1. Preform Moulds. 2. Blow Moulds.

custom plastic molding service

Get Price Quote

custom plastic molding service, pvc cover block, Tile Spacers

Injection Moulds

Get Price Quote

Injection Moulds, precision die casting, Dies, Press Tools

plastic injection molding services

Get Price Quote

plastic injection molding services, fan canopies, spray painting services