Vibrating Grizzly Feeder

Vibrating Grizzly Feeder Features Robust Construction Heavy Duty Application Compact and Modular Design Massive Vibrating Force Excellent Feeding and Scalping Minimal and Easy Maintenance Impeccable Quality High Reliability and Long Life Proven Performance Technical Features Heavy-duty construction for blasted rock and ROM ores Welded steel body reinforced with heavy joists for impact loads Feeder trough fitted with liner plates against wear and tear Compact and low height installation Maintenance free oil bath lubrication Unique feature of stroke angle adjustment to suit application needs Variable speed option Operating angle 0 - 10º down slope Modular heavily built twin-vibrator mechanism with large size roller bearings Synchronized vibrators via an integral gear-train with a V-belt drive from a single motor Retro-fit screen mesh for an integral quarry rejects separation (optional) NAWAGRIZZLY feeders are designed to be heavy-duty machines suitable for feeding blasted rocks and mineral ores to primary crushers.They are robustly built to handle very hard and abrasive ROM materials in harsh and rigorous quarry and mining conditions. The heavily constructed main frame, reinforced with large beams, supports feeder through to withstand the substantial impact loads normally encountered under the truck-dump hoppers. The twin vibrators provide intense linear vibrating force, which effortlessly moves large boulders as well as damp & sticky materials with same ease. A constant en masse speed is ensured. built to high quality standards, NAWAGRIZZLY feeders can handle large volumes at greater efficiencies. They do all three integrated functions, extraction - scalping - feeding, magnificently in any tough environment, and always provide the most economial feeding solution to the user.

...more

Tracked Belt Conveyor

Concrete pouring for piers in metro rail, flyovers, over head freight corridors, canals, etc Stockpiling of large quantity of finished products in screening and crushing plants Truck, ship & barge loading Land filling FEATURES & BENEFITS Heavy duty steel construction Compact transport dimensions & quick set-up time Emergency shut-off for safety Wireless remote controlled conveyor will match up perfectly to any track mounted crusher or screening plant 32" Wide belt with option of Plain or Chevron depending on application Hydraulically operated telescopic frame will facilitate adjustment of conveyor discharge height from 2.2m to 9.3m Hydraulic top folding head section for easy transportation Maximum discharge height of 9.3m will help this machine in application of concrete pouring for piers in metro rail, flyovers, over head freight corridors, etc. Various belt cleaning options available depending upon application Can be containerized for shipping Conveyor feed boot extension available as option Achieves conical stockpile capacity up to 1500 tonnes Model TS3265

...more

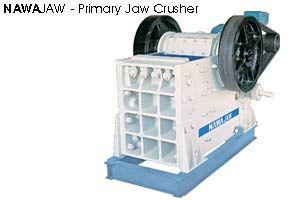

Single Toggle Jaw Crusher

Features Engineered for primary crushing of hard rocks and mineral ores. Its kinematics ensure smooth operation and long life. Totally weld-free construction ensuring long life against shock loads. Robust cast-steel fixed jaw, moving jaw and rear frame - all precision machined for bolting to side plates. Special alloy rolled steel side plates precision machined and rigidly secured by shrink-fitted pins and bolts. Simple mechanical device for adjustment of CSS with no removal or addition of shim-plates. Eccentric main shaft of forged alloy steel with four SKF/FAG heavy duty self-aligning double row roller bearings. Cast-steel flywheels fixed on either side of main shaft for precise balancing and enhanced stability. High crushing efficiency combined with maximum feed size, a large crushing chamber,higher crushing speed, longer stroke, an effective nip angle and a high reduction ratio. High manganese cast-steel jaw plates machined, fully reversible, firmly secured and profiled for smooth flow of material resulting higher throughput.

...more

Screening plant

We are a leading manufacturer of crushing-screening-bulk material handling-aggregate plants & equipment in India. Led by an experienced team of engineering professionals having in-depth technical and application knowledge, we provide complete system solutions to our customers in the field of construction, quarry, mining, cement, thermal power, metallurgical and process industries on turnkey or semi-turnkey basis, for processing of hard rocks and mineral ores.

...more

RADIAL STACKER CONVEYOR

For Wide Range of Stockpile Applications Stockpiling of large quantity of material under conveyor, like GSB grade material in crushing plants for road projects Stockpiling of aggregates & M-sand in conventional crushing plants and crushed ores, coal etc. Simultaneously loading of product bins & ground stockpiling FEATURES & BENEFITS Achieves Conical Stockpile capacity up to 1200 tonnes Radial stockpiles of 8,000 tonnes (approx) through a 120 degree radius & 10,000 tonnes (approx) through a 180 degree radius Hydraulically operated telescopic frame will facilitate adjustment of conveyor discharge height Minimizes segregation of material with hydraulic adjustable discharge height from 3.29m to 9.13m Discharge height adjustment feature will minimize airborne dust particles and minimizes environmental issues Powered Radial drive will minimize stoppage of the plant operation for want of wheel loader to clear off material under head drum of conveyor Hydraulically operated axle extension mechanism will enable the conveyor to switch quickly from transport mode to the radial movement mode Limit switch controlled operation of the radial drive does not require any extra manpower to monitor the operation of the equipment Arc of the Radial movement operation can be changed by shifting the positioning the limit switches in between 90-120 & 180 degrees Compact Electrical-Hydraulic drive arrangement with 15kW motor will ensure smooth running of conveyor drive & radial drive Optional 5th Wheel arrangement for road transport Optional diesel engine drive

...more

Portable Wheel Mounted Station

Features Best Engineered and Proven Jaw Crusher Simple Mechanical Device for Setting Adjustment Heavy Duty Vibrating Grizzly Feeder with Quarry Rejects Separation Deck Heavy Duty 2-Axle Chassis for Travel on Rough Tracks Stable & Vibration Free Design High Capacity & Heavily Built Dump-Hooper with Folding Flaps Easy & Quick Installation by Mechanical Jacking Standard King Pin for Road Haulage Foldable 800mm Wide Conveyor with 3.0m Discharge Height Electronic Soft Starter for Jaw and Variable Speed Drive for Grizzly Completely Wired with Interlock Controls Optional Rejects Conveyor, Magnetic Separator and Dust Suppression Sprays

...more

Nawaspiral Product

Features Fabricated and reinforced tank construction with heavy gauge steel Adjustable weirs for classification control Heavy duty and large diameter seamless tubular shaft designed for minimum deflection Submerged bearing assembly fitted with heavy duty dual roller bearings in a special housing provided with multi layer labyrinth and oil seal protection against ingress of foreign material Front end spherical & roller bearing combination assembly in a special housing provided with oil seals against dust ingression Ruggedly built spiral flights welded to spider arms and protected by abrasion resistant wear liner segments fastened by counter sunk head bolts; the whole assembly designed for a durable and long life Hoisting arrangement for lifting spiral assembly on the submerged bearing side to prevent clogging and for periodic inspection Simple drive train consisting of shaft mounted gear reducer fitted on front end of spiral shaft, V-belts and electric motor Entire drive and front end bearing assembly mounted on a pivoted base such that the spiral assembly can be raised and lowered Electronic frequency controller for step less speed variation of spiral rotation, for setting the classification mesh (optional). A packaged free standing support frame of simple construction and easy installation

...more

NAWACONE - 3000 RBC

3000 RBC NAWACONE - Secondary & Tertiary Cone Crusher Features Best Engineered Geometry Modern Hard Rock Crushing Technology Compact and Sturdy Construction High Production Volumes Low Power Consumption Easy Maintenance Graded Product Output Lower Wear Costs Simple Hydraulic Controls Inbuilt Safety Features Technical Features High speed and Roller Bearing construction - less frictional resistance, less power consumption and longer life Precision machined alloy steel main shaft Perfect dust seal - combined air pressure and mechanical seal protection to all bearings Cartridge type eccentric & main shaft assembly and countershaft assembly for easy removal and maintenance Automatic lubrication of all bearings with built-in machine protection controls Variable stroke that can be set for different throughput and capacities Hydraulic main shaft positioning system - tramp iron release, quick CSS by push button operation and over load protection Four types of crushing chambers - fine, medium and coarse and extra coarse crushing applications Profiled crushing chamber geometry for uniform flow of material, cubical product and well balanced grain distribution High manganese mantle & concave for long life Compact and well balanced machine for fixed plants as well as mobile plant installations Application Areas For secondary and tertiary crushing of Hard rock crushing for aggregates production Limestone crushing for cement industries Iron ore crushing for graded product outputs Metallic and non-metallic mineral ore crushing 3000 RBC NAWACONE 3000 RBC Cone Crusher is ruggedly built with a heavy cast steel body comprising of top and bottom shells to withstand high gyratory crushing forces. The balanced design of the eccentric cartridge and main shaft assembly fitted with Heavy-Duty Roller Bearings, ensure constant alignment and deliver a smooth & frictionless gyromotion. The top end of the main shaft is held in a heavy-duty Spherical Spider Bearing that acts as fulcrum for gyro swing and transfers the rigorous crushing loads to the crusher body through the spider arms. A set of thrust bearings of bronze and steel with a specialized metallurgy supports the main shaft and takes the wear and tear of the vertical crushing loads. The whole shaft assembly is hydraulically supported with a high precision shaft positioning mechanism for CSS adjustment. Automatic tramp iron release is built into the hydraulic circuit protecting the machine from overloads. A highly reliable oil lubrication unit that forms part of the hydraulic power pack and a separate high pressure automated grease lubrication system for spider bearing with all built-in safety features provide a trouble free operation of the machine. A positive air pressure seal combined with a mechanical seal provides full protection to all internals against ingress of dust in severest dusty environments. The drive to the eccentric mechanism is through a heavily built counter shaft assembly and high precision spiral bevel gear and pinion for long term performance. The crushing chamber profiles are designed for uniform flow and optimum material interactions to produce a cubical shaped product. A positive lock-tight fitting of mantle and concave with a backing compound provides an effective cushion to the manganese against the crushing loads. The machine is built to meet varied crushing needs- fine, medium and coarse- of hard rocks and mineral ores. The compact, well balanced, sturdy design and simple-to-operate features make the 3000 RBC NAWACONE an ideal secondary and tertiary crusher suitable for stationary, skid-mounted, portable or mobile crushing in toughest quarries and mines.

...more

SRM500 & SRM400 Durable Nawa Cone Crusher

THE WORLD'S BEST DESIGNED CONE CRUSHERModels: SRM500 & SRM400 Durable NAWACONE Crusher for Secondary, Tertiary and Quaternary Applications Features Exceptional Strength and Durability Combination of Roller Bearings and Hydrostatic Thrust Bearings for High Loads Highest Mechanical Efficiency to the Tune of 97% and Less Power Consumption High Productivity and Superior Product Quality Wide Range of Application Flexibility Fastest and Easiest Wear Liner Change Easy to Operate and Low Maintenance Costs Effective Tramp Iron Relief System Perfect for Portable and Stationary Plants The "Duracone SRM" models have several innovative design, construction and operational features that are unique and adds to their unmatched superior performance in secondary, tertiary and quaternary crushing applications. It is extemely user friendly. e.g. the top shell can be removed and reinstalled in 20 minutes or less, whenever a liner change, or other maintenance needs that call for top shell to be removed, is required. All major maintenance can be done from above the crusher, or from outside the crusher The combination of anti-friction roller bearings in the eccentric drive, and the hydrostatic thrust bearing under the head, allow very high loading, and at the same time very low power consumption when running empty, leaving a high percentage of motor power available for crushing. The SRM models are field-tested for crushing river gravel with a compression strength upto 70,000 psi The low friction in the drive also prevents the shaft spinning when the crusher is running empty, or is lightly fed with the segregated feed, and thus eliminates the need for a shaft brake The anti-friction roller bearings in the drive and eccentric mechanism ensure constant geometric alignment, which reduces wear and tear on the gear drive and thrust bearings compared to those fitted with bronze bushes It is perfectly well balanced, with the c'weights enclosed inside the eccentric mechanism, and thus the c'weights are not subject to wind resistance and abrasion The anti-friction bearing design for the drive and eccentric mechanism means crusher speed changes, if required to sent wider range of applications Low headroom for portable and stationary plants

...more

Gyratory Cone Crusher

Features Engineered for Larger Feed Well Defined Gyro Crushing Action Heavy and Sturdy Construction Large Throughput Volumes Uniform Sized Product Trouble-free Hydraulic Controls Simple Operation & Maintenance Low Power Consumption Lower Wear-per-Tonne Technical Features Sturdy mainframe - heavily built cast steel top shell and bottom shell High tensile heat-treated alloy main shaft, precision machined and shrink-fitted with a cast steel core High precision gyro-components - cast steel eccentric, specialized journal bearings, high carbon-steel bevel gear & pinion, special metallurgy thrust plates - all designed to minimize wear and friction Spherical plain spider bearing assembly, grease lubricated for effortless fulcrum action and free rotation of the main shaft A full-proof dust steel arrangement for effective protection of eccentric bearing and gear-pinion Catridged counter-shaft assembly in roller bearings adequately lubricated from auto-lube system A compact and combination hydro-lube power pack with inbuilt safety features for trouble free operation Long and steeply tapered crushing chamber for larger secondary crushing volumes Improved wear-resistant manganese mantle and segmented concave, both secured by positive lock-tight fitting with an expoxy backing Application Areas Secondary crushing of a variety of hard stones and minerals: Granite Basalt Quartzite Limestone crushing for cement industries Manganese ore Metallic and non-metallic mineral ore crushing NAWACONE 3000 GLH The Long Head model is built for larger feed and capacity. It is sturdily built to withstand severe crushing loads generated by toughest of the rocks. The main body is made up of top and bottom shells of heavy cast steel sections, precision machined to receive the spider bearing, eccentric and counter-shaft assemblies. The crushing chamber comprising of non-choking curved mantle and concave of high manganese castings, is designed to nip larger lumps of primary crushed rocks. And higher crushing volumes are achieved with evenly distributed wear. The forged mainshaft of special steel is precision machined and fitted with a cast steel core on which the mantle is mounted. A positive dust seal arrangement effectively prevents ingress of dust from the crushing area into the eccentric bearing elements and bevel-pinion gear train. The high precision gyro elements comprising of cast steel eccentric, set of inner and outer journal bearings of special metallurgy are driven through a bevel gear-pinion and counter-shaft assembly running on antifriction bearings. The eccentric and mainshaft are supported at bottom end by hydraulic pressure through a set of thrust plates for taking the vertical loads. A hydro-lube system incorporates all machine-safe controls. The lube pump circulates and lubricates the gear train, main & counter shaft bearings. The hydraulic circuit ensures smooth CSS adjustment and trouble-free operation of the crusher. The spider bearing in the top shell is grease-lubricated either manually or by an automated grease pump (optional).

...more

Grizzly Feeder

NAWA ENGINEERS combine their equipment expertise with system design skills for producing required products of a particular project task. NAWA undertakes turnkey responsibility to translate the system flow into reality of well-built plant. Our project engineering and implementation team works very closely with the client to get the most effective yield - both gradation and shape - of the products.

...moreBe first to Rate

Rate ThisOpening Hours