Vacuum Water Separator

Features: Very fast and highly effective water removing device, meant for high duty applications. Easy full automatic operation. Removes water, moisture and air bubbles:- Dissolved water: 80%- Free water: 100%- Air bubbles: 100% Viscosity range from 10 ~ 680 cSt. Oil temperature from 40°C ~ 70°C. On demand, all systems can be supplied with ATEX/EX certification. Benefits: Extends oil life:-Important reduction of waste oil & disposal cost.-Reduces the purchasing cost of oil. Prevents machines failures and extends the machine life:-Prevents pump cavitations.-Prevents machine wear caused by rust.-Reduces the maintenance cost.-Improves the productivity. Low running cost-No consumables, one-time investment.

...more

Quicktoron Air Bubble Removing Machine

Features: Quicktoron is a device to remove air bubbles from liquids.It’s based on the cyclone principle, and very efficiently eliminates all the fine air bubbles trapped and mixed inside the fluid. Quicktoron also helps to retain the filtration performance of filter elements. Most air bubbles have a larger sizes than solid contaminants. When these air bubbles go through the filter elements, they create bigger channels, allowing contaminants to pass through without being captured, and dropping filtration performance of the oil filters.Quicktoron devices are very compact, easy to install, and offer a very economical solution to remove air bubbles quickly and efficiently.Typicaly Quicktoron is used in combination with our OSCA-series. Consequences of air bubbles in oil: Createsexcessivenoiseandvibration. Increases friction and wear of moving parts. Accelerated oxidation of the fluid Acceleratedmetalcorrosion.Lowercoolerefficiency. Causesmeasurementerrors. Benefits of Quicktoron: Extendsoillife. Improves machine reliability and component life. Improvescoolersefficiency. Improves power transmission and saves on energy

...more

oil removing device separating oil

Features: Off-line oil removing device separating oil and capturing contaminants simultaneously. Based on our 2-stage coalescent oil removal principle, it collects all the floating oil from water based fluids. Typical use for removing oil from washing fluids. The units are equipped with automatic oil sensor and oil drain function. Maintains the NAS grade of the fluid. Reduces the amount of waste fluid dramatically.

...more

magnet separator

Features: Fine contaminants mixed in fluid cohere and settle while flowing through our unique active magnetic field. It functions semi permanently, and therefore zero running cost. Maintenance Free for a long time. Suitable for both water soluble and oil based fluid.

...more

MAGNET BARRIER SYSTEM

Features: No operation cost No power consumption/replacement part because permanent magnets are used for solid-liquid separation Resistant to oil and heat because SUS is used as the main body material Removes fine chips and abrasive grains from machine tools Removes fine cast-iron/iron chips (sludge) of 1 μm or larger than suspend or precipitate in the tank and cause putrefaction of liquid coolant uid in combination with the oil cleaner

...more

Filter Elements

The original and still the best. Triple R’s continuous investment in research and development delivers the highest standard of efficiency in oil filtration. Protecting your investments while boosting productivity.Our filter elements are designed to cleanse industrial oils, removing everything from solid particles to water to sludge, varnish and oxidation residues. All within a single element - a Triple R unique, unmatched by any filter manufacturer worldwide. A wide range to fit every application. All Triple R filter elements are Multipass-tested and guarantee consistent and reproducible micron ratings and filtration efficiency. The filter element range comes in 4 sizes (30, 50, 100 and 300 size), in various filter materials from cellulose to polyester to PP, and in 2 different setups (standard setup or ‘double stage’ D-series setup). The Triple R 3-stage filtration concept. The axial flow creates a 114 mm thick filter buildup. The combination of Triple R’s special cellulose material and the thickness of the element allows absorbing of water and sludge. The lower part is compressed by a carton box, creating an even finer filter medium. Big particles stay on top of the element. Smaller particles are captured in the uppernon-compressed part. The smallest particles are captured in thelower compressed part TIP: use Triple R to analyse your systems condition. When you open the lid of our Triple R housings, you can look at the top of the filter element inside.The outlook of the filter element and the type of contaminants present on the top allow to draw conclusion about your systems condition.

...more

Conveyor Magnets

Magnets(using permanent magnets)can be used for both oil-base and water-base fluid. Collect oilfluid until the last drop, and recycle it.50% less industrial waste management cost in many case. Low operation cost and low maintenance cost, 15 in many cases. The used cutting fluid travels to a dirty tank from a gear grinder - any filtration magnets located inside the dirty tank capture magnetic metal powder - a scraper scrapes off the sludge - a roller squeezes out cutting fluid from the sludge - the sludge is discharged. Cyclone-separator or backwashing filters remove non-magnetic grinding powder and binding agent from the cutting fluid - the fluid travels to a clean tank.

...more

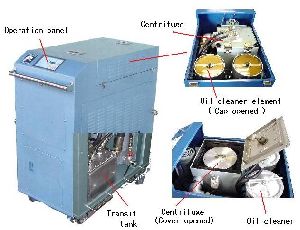

Oil Cleaning Machine

Features: Excellent purifying performance in the CUBE, a centrifuge removes large foreign sludge and a micro filter removes microscopic particles. As a result, it is possible to considerably purify oil as well as prolong the intervals between micro filter replacements Reduction of the new oil purchase cost and the waste oil management cost. Typical applications: Lubricating oil tank of a diesel engine High load contamination oil Typical applications: Lubricating oil tank of a diesel engine High load contamination oil

...more

Bypass oil cleaners

Features: Very compact and light bypass oil cleaners. Connects directly to the high pressure line. No motor and pump necessary. Designed for hydraulic systems up to 350 bar system pressure. All BU bypass old cleaners are fitted with M-series 3μ absolute filter elements (beta ratio ß3 >400). With built in pressure and flow control valve, safety valve and pressure gauge for checking element change. Low running cost, easy installation & maintenance. Also available for water glycol fluids; with coated housing and WG element. Typical applications: Injection moulding machines. Die-casting machines, metal working machines, like bending-, cutting-, punching machines. Mobile hydraulic equipment. All hydraulic systems with continuous pressure and fitted with proportional or servo-valves, and other high-tech hydraulic equipment. Benefits: Prevents trouble to the hydraulic equipments. Improves machine reliability and productivity. Longer life of all hydraulic components, pumps, servo-valves and other equipment. Extends oil life by up to 40.000 hrs. Very important reduction of oil consumption and the resulting waste oil. Discharges the full flow filters and extends their life. Important reduction of maintenance costs.

...more

bypass filter

In the past some oil manufacturers pretended that bypass filters remove oil additives. But oil additives are in solution and mixed within the base oil. Even if we wanted to, Triple R bypass filters can not remove additives because additives have a far smaller molecular size than the 2, 3 or 5 micron rating of Triple R filter elements.

...more

SE AL100 1R Oil Filtration

Be first to Rate

Rate ThisOpening Hours