Vibratory Screens

Our Centre shaft Screens are specially designed for bigger, medium and fine size separation applications. Our screens are of flexible inclined mounting are ideal for Scalping, primary and secondary crushing and for final screening of a finished fraction. Available in two, three & four deck options in 6 sizes with capacity range from 100tph to 400tph. Range Include circular, linear& elliptical motions ADVANTAGES Design offers maximum flexibility with minimum downtime. Drive assembly designed for flexibility, safety, easy service and maintenance. Custom built to ensure high performance in aggregate & mining industries.

...more

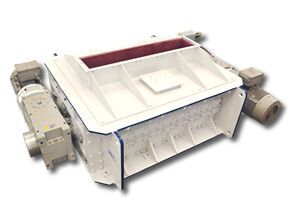

Vibrating Grizzly Feeder

Our Grizzly Feeders are designed for high capacitiesup to 1000TPH in primary and feeding applications. They have a standard hopper volume of 15 to45 m3 with a max feed size up to 1250mm. available in 6 variants. They are provided with Grizzly bars for separation of (-)50mm feed to Jaw crusher there by enhancing the capacity of plant and Primary crusher. The natural deleterious, mud can be separated from feed so that can improve the quality of raw material to crushing and dust free aggregates.

...more

Vertical Shaft Impact Crusher

Working closely with our customers, and listening carefully to their needs, has led to many new solutions in the design of VSI to improve business for crushing customers. OUR OFFERINGS : Well balanced rotor table fitted with special carbide tips (easy replaceable) for long life Well designed outer ring with anvil or rock - on - rock ports Central shaft fitted with antifriction bearings for efficiently transferring the power, speed to meet the crushing task Optional hydraulic arrangements to lift the top cover for easy accessibility to main crusher parts In the aggregate and quarrying sector, it is used for production of high-quality manufactured sand and premium shaped aggregates. Other areas include aggregates for dam construction, Ideal for various minerals clinker, glass, slag, etc and industrial minerals plants crushing extremely abrasive high-value materials.

...more

Surface Miner

Puzzolana PMM 2205 is an economic solution for selective surface mining. Built in features ensure high quality product sizing and mixing, and level benches ensuring minimal wastage and safe operation.

...more

Stacker Reclaimer

Designed for heavy duty operation and accepts products from all types of crushing installations For raw materials in the Cement, Coal, Pulp,Paper,Mining,Power Plants and ports Modular Design Concept Capacity upto 2500 TPH On specific we can go upto 5000 tph

...more

PUZZOLANA roll crushers

PUZZOLANA roll crushers are mainly designed to handle medium to hard feed material. Toothed roll shells are used for primary crushing where as smooth roll shells are used for fine crushing. The crusher consists of base frame of welded construction with one roll fixed and the other roll mounted on rocker arms. These roll crushers are equipped with overload protection and a separate driver for each roll.

...more

Sander

To cater to the enhanced requirement of manufactured sand as stipulated norms of International standards, lead to the development fine & super fine Cone crushers of Floating shaft & bearings design for high reduction and high capacity in relation to size. They are to give very good product shape. The sanders are available in three sizes and can accept a feed up to 40mm and produce sand (-)4.75mm with control on (-) 150 microns up to a capacity 50TPH. OTHER FEATURES AND BENEFITS : Introduced sander for producing the manufactured sand from the feed size (-)40 to 5mm in to (-)4.75mm sand as per IS 383, Zone II. Feed from secondary stage (-)40mm to produce (-)20 -10mm & sand (-) 4.75mm product with (-)150 micron in the specified limits. Enhanced requirement of 0-16mm (170TPH) capacity for bituminous layers in road projects or for concrete works.

...more

Sand Crusher Machine

To cater to the enhanced requirement of manufactured sand as stipulated norms of International standards, lead to the development fine & super fine Cone crushers of Floating shaft & bearings design for high reduction and high capacity in relation to size. They are to give very good product shape. Introduced sander for producing the manufactured sand from the feed size (-)40 to 5mm in to (-)4.75mm sand as per IS 383, Zone II. Feed from secondary stage (-)40mm to produce (-)20 -10mm & sand (-) 4.75mm product with (-)150 micron in the specified limits. Enhanced requirement of 0-16mm (170TPH) capacity for bituminous layers in road projects or for concrete works.

...more

PLASTER SANDER

The restrictions in the natural sand mining created shortage of fine sand for plastering works with control on (-)75 microns lead to the development super fine Cone crushers of Floating shaft & bearings design for high reduction capacity in relation to size. They are to give very good product shape. The Plaster sanders are available in three sizes and can accept a feed up to 25mm and CSS at 3-6mm setting and produce plaster sand (-)2.36mm with control on (-) 150 microns up to a capacity 40to 50 TPH. The plaster sand is as per IS1542i.e 100% (-)2.36mm.

...more

MOBILE SCREEN PTS 1552-3

Puzzolana PTS 1152-3 is a mid sized mobile screen aimed at end users requiring high production and execellent quality finished product. User benefit include a quick setup time, convenient screen mesh access & transverse sliding power unit arrangement for easy maintenance. FEATURES AND BENEFITS High capacity upto 500 TPH ( Depending on feed size, mesh size & material type ) Low fuel consumption Grid power supply option Maximum feed size 150 mm Engine protection shutdown system Power unit featuring a transverse engine arrangement to aid access & serviceability Maximum mobility with heavy duty, low ground pressure crawler tracks Quick setup time High performance hydraulic system Hydraulically folding conveyors for transport Fines conveyor drop down facility to aid bottom deck mesh access OPTIONS 2 deck Grid Power

...more

MOBILE JAW PTJ 1176

Puzzolana offers track jaw plant range with a compact, efficient and high output Jaw Crusher Plant. With its user friendly design and quick setup time, it is ideally suited for Mining, Construction and Quarrying industry FEATURES AND BENEFITS High capacity upto 250tph Reliable high performance Low fuel consumption High output and excellent reduction capability Heavy duty wear resistant hydraulic folding hopper Feed hopper with wedge fixing system Stepped self cleaning grizzly feeder with under feeder screen option Mechanical crusher setting adjustment Easy access power unit canopy Dirt Conveyor OPTIONS Dust suppression system Electro Magnetic separator Lighting Grid power supply Rock Breaker Radio remote control Belt weigher Central Auto lube system Wire mesh for under screen Discharge conveyor dust hood

...more

Jaw crusher

1 Set(s) (MOQ)

puzzolana offers complete range of single toggle jaw crushers for all types of rock, ores & minerals. these crushers are designed to operate in most rugged environment and need less maintenance. available in 14 sizes 30" x 20" to 72" x 60" - upto 1000 tph. puzzolana's range of single toggle jaw crushers are designed with an upward facing toggle system. this produces a "flat elliptical movement" at the bottom of the swing jaw which increases the efficiency of the crushing. the unique elliptical motion of the swing jaw guarantees a highly efficient production rate at every setting. this special motion of the jaw also minimizes scrubbing action common in single toggle jaw crushers. the design also permits an extra long jaw length which in turn means more crushing strokes giving a high ratio of reduction. the capacity of jaw crusher can be maximized by providing continuous regulated feed. the under size material (below css) should be removed from the feed to eliminate packing and excessive wear on the jaws. these crushers are designed for exceptionally heavy duty and continuous operations. these are well suited for stationary and mobile applications. to select proper jaw crusher provide the following data : type of material to be crushed. bulk density of feed meterial. maximum feed size & feed gradation. characteristics of feed material(hard, soft, slabby, moist or wet, sticky, contains clay etc.) capacity in tons per hour. method of feeding to be adapted and capacity of the dump trucks.

Type : Jaw Crusher

Condition : New

Country of Origin : India

...more

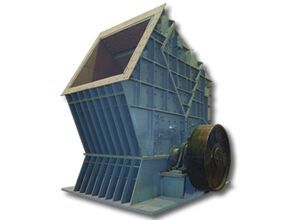

Impact Hammer Mills

Best suited for Limestone, Coal, Gypsum and softer ores Reliable performance & increased output Rugged design and construction Suitable for secondary and tertiary applications Un-effected by foreign particles

...more

Horizontal Shaft Impact Crusher

Rugged Construction suitable for Primary and Secondary application Best suited for hard materials like basalt and granite Extremely sturdy and all the parts are easily accessible for quick maintenance. High utilization of breaker bars and can be quickly reversed or replaced Rotor fabrication is well balanced to minimize vibration.

...more

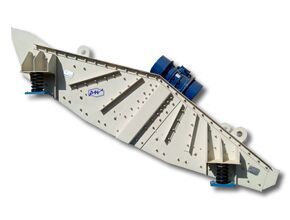

HIGH SPEED SCREENS

Puzzolana High Speed Screen is most effective for Fine Screening application with Low Amplitude. High Slope at the feed end enables the material to move faster and fines pass through the sieve meshes quicker to allow stratification by the separation of large particles from fine ones. The inclination is less in the middle and discharge Section, which reduces the transport speed in the sections a good Separation Achieved. Available in single & double deck options and from size 1500x 4200mm to 2400x 6000mm up to 100tph capacity for separation of 1 to 2mm fractions in (-)6mm. ADVANTAGES It is very efficient screen when there is high Content of fines in the feed. Very Compact Screen Easy to Install. Linear Vibration With High G Force (5 G),with Vibrating Motors. Improved Efficiency in Sizing Material due to formation of a thin Bed Depth.

...more

H TYPE CONE CRUSHER

Our H type cone crushers are of advanced design with high capacity in relation to size, are used in the secondary & tertiary applications. They have high reduction efficiency and give very good product shape. Our H-Type cone crushers are available in 18 variants of capacities from 50 to 400TPH. A combination of chamber range, and high motor power give the crusher a wide range of application combinations to suit different installations. FEATURES AND BENEFITS: Excellent versatility due to a wide range of chambers with different feed acceptance. Full control of the process. Easy to maintain. Extremely reliable H-Type cone crushers are suitable for a wide range of applications, including quarrying & mining . End products are final aggregates for concrete and road projects, Cone crusher series combine extremely high performance with low total cost.

...more

Grizzly Feeder

Our Grizzly Feeders are designed for high capacitiesup to 1000TPH in primary and feeding applications. They have a standard hopper volume of 15 to45 m3 with a max feed size up to 1250mm. available in 6 variants. They are provided with Grizzly bars for separation of (-)50mm feed to Jaw crusher there by enhancing the capacity of plant and Primary crusher. The natural deleterious, mud can be separated from feed so that can improve the quality of raw material to crushing and dust free aggregates.

...more

G TYPE CONE CRUSHER

Our Secondary gyratory crushers are robust crushers, they are designed to give optimal capacity in crushing, increasing the total capacity in the crushing process. Available in 5 sizes with capacities from 100 to 550tph with feed sizes up to 450mm. The crushers in the G - series have a large feed opening and a grooved mantle, making them suitable for crushing large boulders. The optimized nip angle of the crushing chamber increases capacity, output and wear life. We have a long history of developing cone crushers, and we understand how to give you the ultimate setup for maximum productivity and profitability. Today we have thousands of cone crushers in operation the leading Cone crusher series. G-Type cone crushers are suitable for a wide range of applications, including quarrying & mining . End products are aggregates for further processing in case of concrete and road projects, (-)150mm boulders for Dam projects and railway ballast. cone crusher series combine extremely high performance with low total cost.

...more

feeder breaker

A well-built & solid frame with hopper capacity of 30 cu.m. Powerful chain conveyor & drive. Robust drum type crusher roll design for efficient breaking. Overload protection, with soft starter. Centralised lube system or auto lube system. Customized/Optional equipment for Rock breakers and other configurations of hopper capacity & discharge variations.

...more

DRY CLASSIFIER

Dynamic Air separator / Classifier is a simple equipment having two cone /cylinder (inner & outer and an impeller with vanes built with wear resistant material to generate whirling air circulation action. The fines from the crushing plant is fed through feed inlet and dropped by gravity on the Auxiliary fan. The Auxiliary fan is connected to the drive motor through a housing. The Rpm of fan can be throttled through VFD fitted to the motor to control the amount of fines to be separated. The main fan creates continuous circulating air into which the distributor disperses the fines. Material acted upon the distributor plate is subjected to the following forces namely, Centrifugal force, Ascending air force, Gravity force. Fine particles below 150 microns size are lifted by the ascending air current and pass between the blades of auxiliary and Main into the outer cone of the separator. The (-) 150 microns transferred into the outer cone are discharged from the unit bottom in to a conveyor and transferred into a closed tank through a conveyor. Underneath the separating zone there is return air vanes are located, the main fan moves the air to separating zone from the return air vanes. The separation of fines can be attained by reduction is descending air velocity and also by adjusting the direction of return air vanes. Heaviest particle mainly + 150 microns - 5mm not ascending will fall to the bottom of the inner cone and on to a chute and stock plied on the ground through a conveyor belt. which is classified Sand conforming to the standards prescribed in IS 383. Air velocity , volume of Air and speed of Rotation are important factors to achieve the good separation of fines from heavier particles .The Moisture content in the input material .As per the available data it can operate up to 2-3% moisture by wt in the feed material. The Dry classifiers are custom designed with varying capacity depending on the input fractions percentage. They are available in three variants up to a capacity of 250 Cu.M/hr. ADVANTAGES Conserves water – As no water is required. As a closed system – no Pollution. Ease of operation & economical as low operating cost. Quality - With variable speed can monitor the fines content.

...more

grab dredger

CUTTER SUCTION DREDGERS - The highly economical & performance oriented PMF Cutter Suction Dredgers comes with superior technology and robust design and ensures for high reliable operations and generates efficient output. DREDGERS ARE EQUIPPED WITH : Hydraulic driven sub merged sand pump 2 auxiliary engines, one for Ladder mounted hydraulic submerged pump one for hydraulic system (winches,spud lifting rams,cutter drives, etc..,) Optional Equipments like spud carriage/Air conditioning/ Generator/Belt Driven pump, etc., Models can be customized based on Customers specific requirement/requests.

...more

dredge equipment

The highly economical & performance oriented PMF Cutter Suction Dredgers comes with superior technology and robust design and ensures for high reliable operations and generates efficient output.Hydraulic driven sub merged sand pump 2 auxiliary engines, one for Ladder mounted hydraulic submerged pump one for hydraulic system (winches,spud lifting rams,cutter drives, etc..,) Optional Equipments like spud carriageAir conditioning GeneratorBelt Driven pump, etc., Models can be customized based on Customers specific requirementrequests.

...more

Coal Feeders

Powerful chain conveyor & drive. Robust drum type crusher roll design for efficient breaking. Overload protection, with soft starter. Centralised lube system or auto lube system. CustomizedOptional equipment for Rock breakers and other configurations of hopper capacity & discharge variations.

...more

BUCKET WHEEL TYPE CLASSIFIER

The dry feed material 0-5mm from the crushing plant and water is added in to the fabricated tank equipped with slow moving screw where decantation takes place with low turbulence flow. Water with (-) 150 microns will be carried away by the flowing water moves in the opposite side and collected in weir and discharged outside. The washed /Classified cleaned sand, through rotation of the screw against the water stream flow The cleaned sand will be lifted by the rotating bucket wheel fall on the De watering screen. The slotted perforations in the special screen deck allows to remove water from the washed sand and water goes back in to the washing process, The cleaned & dewatered sand falls on to belt conveyor and to stock Available in 3 variants of capacities up to 200TPH.

...moreBe first to Rate

Rate ThisOpening Hours