PUZZOLANA roll crushers

Get Price Quote

PUZZOLANA roll crushers are mainly designed to handle medium to hard feed material. Toothed roll shells are used for primary crushing where as smooth roll shells are used for fine crushing. The crusher consists of base frame of welded construction with one roll fixed and the other roll mounted on rocker arms. These roll crushers are equipped with overload protection and a separate driver for each roll.

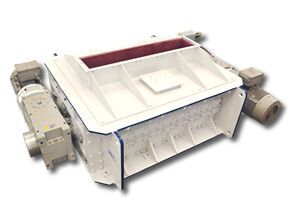

Double Roll Crusher

Get Price Quote

Best Deals from Roll Crusher

Single Roll Crusher

Get Price Quote

Bevcon Single Roll Crusher is typically primary crusher. The crushing technique involves the operations like Impact, shear and compression. The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor. Material is crushed between teeth and a breaker plate consisting of hard liners. Providing a crushing ratio of up to 6:1, Bevcon Single Roll Crushers reduce large size particles in the feed to a medium size, while producing a low percentage of fines. The Single Roll Crusher design is very effective in reducing lumpy material because of the interrupted opening between the roll teeth and the corresponding grooves in the crushing plate liners.

Roll Crusher

Get Price Quote

Bevcon Single Roll Crusher is typically primary crusher. The crushing technique involves the operations like Impact, shear and compression. The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor. Material is crushed between teeth and a breaker plate consisting of hard liners. Providing a crushing ratio of up to 6:1, Bevcon Single Roll Crushers reduce large size particles in the feed to a medium size, while producing a low percentage of fines. The Single Roll Crusher design is very effective in reducing lumpy material because of the interrupted opening between the roll teeth and the corresponding grooves in the crushing plate liners.

Double Roll Crusher

Get Price Quote

Bevcon toothed double roll crushers are equipped with two identical crushing rolls rotates towards each other. These crushers are ideal at different stages of crushing primarily envisaged to generate very less fines. Hence the crushing ratios are limited to 4 :1. Since both rolls rotate in same speed, there is no relative motion between roll surfaces. Material entered in crushing chamber is crushed between two crushing rolls. Crushing is accomplished purely by compressive action. In both the rolls one will be stationary and one is self adjustable

Toothed crushers

Get Price Quote

Roll Crusher

Get Price Quote

Roll Crusher, compacting factor apparatus, Ultrasonic Pulse Velocity Tester

Roll Crusher

Get Price Quote

Roll Crusher, Ring granulator, Pneumatic Conveying System

Double Roll Crusher

Get Price Quote

Double Roll Crusher, Pneumatic Conveying Systems, Belt Conveyor System

Roll Crusher

Get Price Quote

Roll Crusher, Bag Filters, Chimney, silo, Bucket Elevators