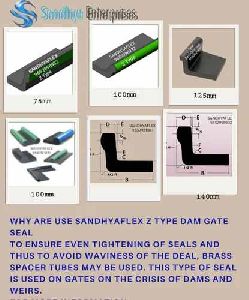

Z Type Musical Note Dam Gate Seal

2,200 Per Meter

50 Meter (MOQ)

Z-type dam gate seals are specialized rubber or elastomeric seals used in hydraulic structures, particularly in dams and water control gates. These seals play a critical role in ensuring water-tightness and preventing leakage at the gates of dams, sluices, spillways, and other water retention or control structures.### Key Uses and Features of Z-type Dam Gate Seals:1. **Water Tightness**: Z-type seals are designed to create a strong, watertight seal between the gate and the frame or the gate and the sill. This is essential to prevent water leakage through the gates, ensuring the controlled flow of water.2. **Durability**: These seals are typically made from durable rubber or elastomeric materials that can withstand harsh environmental conditions, including exposure to UV radiation, water, and varying temperatures.3. **Flexibility and Compression**: The Z-shape of the seal allows it to flex and compress as the gate moves, ensuring a consistent seal even under varying pressures and movements. This flexibility is crucial for maintaining a seal over long periods, despite the opening and closing of the gates.4. **Shock Absorption**: The Z-type design also helps in absorbing the impact and shock when the gate is operated, protecting both the gate structure and the sealing material from damage.5. **Ease of Installation and Maintenance**: These seals are often designed for easy installation and replacement. Their shape allows them to be fitted into grooves or attached using fasteners, and their material properties allow for long service life with minimal maintenance.6. **Applications**: - **Dam gates**: To control the flow of water and manage reservoir levels. - **Sluice gates**: For controlling water flow in irrigation channels, canals, and drainage systems. - **Spillways**: To prevent leakage in spillway gates, ensuring that water flows over the spillway as intended. - **Lock gates**: Used in canal lock systems to prevent water from seeping between the gates.### Advantages:- **Long Lifespan**: Due to their robust construction and materials.- **Effective Sealing**: Provides reliable water-tightness even under high pressures.- **Resistance to Environmental Factors**: Resistant to weathering, ozone, and chemical exposure.In summary, Z-type dam gate seals are essential components in hydraulic engineering, ensuring the effective and safe operation of water control structures by preventing leaks and maintaining water tightness.

Type : Dam Gate Seals

Country of Origin : India

Size (Inches) : The dimensions of a **Z-type dam gate seal** can vary depending on the specific requirements of the

Application : Industrial

Color : Black

Steam Thickness : The dimensions of a **Z-type dam gate seal** can vary depending on the specific requ

Tensile Strength : The tensile strength of a **Z-type dam gate seal** is a critical property that dete

...more

Yarn Braided Water Hose IS 444

45 Per 180 Meter

200 Meter (MOQ)

sandhay enterprises manufacturer and supplier of yarn braided water hose size:12mm id to 50mm id working pressure :10kg/cm2 construction: lining : smooth lining of suitable rubber compounds with good oxidation resistance. in addition for type 3 hose, lining is resistance to oil mist. reinforcement : plies of rubber impregnated woven textile or braided high strength natural/synthetic fibre. cover : smooth/fluted/cloth marked finish, suitable rubber compound resistant to abrasion and weather.

Type : Braided Hose Pipe

Color : Black

Pressure : Low

...more

Yarn Braided Air Hose IS 446

100 - 150 Per Meter

200 Meter (MOQ)

Sandhya Enterprises Manufacturer and Supplier of Yarn Braided Air Rubber Hose as per IS :446 size:12mm to 50mm Pressures: Type 1 for a W.P. 0.7MPa & Min. B.P. 2.8MPa. Type 2 for a W.P. 1.0MPa & Min. B.P. 4.0MPa. Type 3 for a W.P. 1.4MPa & Min. B.P. 5.6MPa.

Type : Braided Hose Pipe

Color : Black

Pressure : Low

...more

XLPE Chemical Hose

350 - 850 Per Meter

15 Meter (MOQ)

An XLPE (Cross-linked Polyethylene) chemical rubber hose is a specialized hose designed for the transfer of various chemicals, acids, and corrosive substances. XLPE is a thermosetting plastic material that offers excellent chemical resistance, high temperature resistance, and durability, making it suitable for handling a wide range of aggressive chemicals. Here are some key features and characteristics of XLPE chemical rubber hoses: 1. Material: XLPE chemical rubber hoses are constructed using a tube made of cross-linked polyethylene. This material provides exceptional resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. The tube is reinforced with multiple layers of synthetic yarn or wire for added strength and flexibility. 2. Chemical resistance: XLPE hoses are highly resistant to a wide variety of chemicals, making them suitable for applications involving aggressive or corrosive substances. They can handle chemicals such as sulfuric acid, hydrochloric acid, sodium hydroxide, ethanol, methanol, and many others. 3. Temperature resistance: XLPE hoses can withstand a broad temperature range, typically from -40°C to +120°C (-40°F to +248°F). This temperature resistance allows for safe handling of chemicals at both high and low temperatures. 4. Flexibility: XLPE chemical rubber hoses are designed to be flexible, allowing for easy maneuverability and installation. The flexibility of the hose enables it to be used in various industrial settings, including chemical plants, refineries, manufacturing facilities, and laboratories. 5. Safety features: XLPE hoses often have additional safety features to ensure the safe handling of chemicals. These may include electrostatic dissipation (ESD) properties to prevent static build-up and grounding, as well as smooth or corrugated covers for enhanced abrasion resistance and operator protection. 6. Size and pressure ratings: XLPE chemical rubber hoses are available in a range of sizes, typically ranging from 3/4" to 4" in diameter. The hoses are designed to withstand specific working pressures, which can vary depending on the manufacturer and application requirements. It is important to select a hose with the appropriate size and pressure rating for the intended use. 7. Compliance and certification: XLPE chemical rubber hoses should comply with industry standards and regulations for chemical resistance, safety, and performance. These standards may include ISO (International Organization for Standardization), EN (European Norm), or specific industry guidelines. Proper inspection, maintenance, and testing of XLPE chemical rubber hoses are essential to ensure their integrity and safe operation. Regular checks for signs of wear, damage, or degradation, as well as conducting pressure tests and visual inspections, are necessary to maintain hose performance and reliability. It is recommended to consult with reputable hose suppliers or manufacturers to select the appropriate XLPE chemical rubber hose based on the specific chemical compatibility and application requirements.

Type : Chemical Rubber Hose

Material : Rubber

Color : Green

...more

Wire Saw Rubber Ring

500 - 600 Per piece

A wire saw rubber ring, also known as a wire saw rubber spacer or wire saw rubber guide, is a specialized rubber component used in wire sawing operations, particularly in the construction and manufacturing industries. Wire saws are cutting tools that use a continuous wire loop with abrasive particles to cut through a variety of materials, including concrete, stone, metal, and more. Wire saw rubber rings play a crucial role in guiding and supporting the wire during cutting, protecting both the wire and the material being cut. Here are some key features and functions of wire saw rubber rings: **Key Features:** 1. **Material:** Wire saw rubber rings are typically made from high-quality rubber or elastomeric materials, which are chosen for their flexibility, durability, and resistance to abrasion. 2. **Design:** They are often designed as round or cylindrical rubber components with a central hole through which the cutting wire passes. The design allows for easy installation and secure positioning of the wire. 3. **Size and Dimensions:** Wire saw rubber rings come in various sizes and dimensions to accommodate different wire diameters and cutting applications. 4. **Abrasion Resistance:** These rubber rings are specifically engineered to withstand the abrasive nature of wire sawing operations, ensuring that the wire remains protected and stable during cutting. **Functions:** The primary functions of wire saw rubber rings include: 1. **Wire Support:** They provide support and stabilization to the cutting wire, ensuring that it maintains the desired cutting path and minimizes vibration or wobbling during the cutting process. 2. **Wire Protection:** Wire saw rubber rings protect the cutting wire from excessive wear and damage caused by friction with the material being cut, extending the life of the wire. 3. **Guidance:** They help guide the wire in a straight and controlled manner, ensuring precise and accurate cuts in various materials. 4. **Reducing Wire Slippage:** These rubber rings help prevent the wire from slipping or detaching during cutting, which could lead to inefficient or incomplete cuts. 5. **Vibration Dampening:** Wire saw rubber rings absorb and dampen vibrations generated during cutting, contributing to smoother and more controlled cutting operations. **Applications:** Wire saw rubber rings are commonly used in a variety of applications and industries, including: 1. **Construction:** In the construction industry, wire saws are used for cutting concrete, reinforced concrete, and other construction materials to create openings, remove structures, and make precise cuts. 2. **Stone and Granite Cutting:** Wire saws equipped with rubber rings are used for cutting stone, granite, and other natural or engineered stone materials in the stone industry. 3. **Metal Cutting:** Wire saws can be employed in metalworking processes to cut and shape metal materials. 4. **Demolition:** They are used in demolition operations to cut and remove large concrete structures and reinforced concrete elements. 5. **Manufacturing:** Wire saws with rubber rings are used in manufacturing processes for precision cutting of various materials. Proper installation and maintenance of wire saw rubber rings are essential to ensure their effectiveness and longevity. Inspecting the rubber rings for wear and damage and replacing them when necessary is important for maintaining cutting quality and protecting the cutting wire.

Brand Name : SNDHYAFLEX

Material : Rubber

...more

WAVE Floor Mat

1,200 - 1,500 Per piece

In some contexts, "VIP Floor Mat" may refer to a specific brand or type of floor mat, but without additional information or context, it's challenging to provide a precise answer. Floor mats come in a wide variety of styles and purposes, so the term "VIP Floor Mat" could encompass several possibilities. If you have a specific question or need information about a particular brand or type of floor mat referred to as "VIP Floor Mat," I would recommend providing more details or context, such as the intended use, material, or any specific features you're interested in, so I can provide a more accurate response.

Material : Rubber

Shape : Sqaure

Color : black

Application : Floor Mat

Size : Multisize

...more

Water Treatment Plant PVC Water Stopper

140 Per Meter

500 Meter (MOQ)

A PVC water stopper is a construction material commonly used in concrete structures to prevent the passage of water through construction joints, expansion joints, and other openings. It's typically made of high-quality polyvinyl chloride (PVC) and is used to ensure a waterproof seal in various applications, including basements, tunnels, reservoirs, swimming pools, and water treatment plants. Key Features of PVC Water Stoppers: Waterproofing: The main function is to prevent water from seeping through joints in concrete structures. Durability: Resistant to chemical attack, corrosion, and degradation over time, making it ideal for long-lasting applications. Flexibility: PVC water stoppers are flexible and can expand or contract to accommodate joint movements. Ease of Installation: They are relatively easy to install during the construction phase, as they can be embedded in the concrete joints. Variety of Designs: Available in different shapes and sizes to suit specific joint configurations (e.g., straight, L-shaped, or T-shaped). Cost-effective: PVC is relatively affordable, providing an economical solution for waterproofing needs. Applications: Foundation and basement walls: To prevent water ingress in subterranean structures. Water tanks and reservoirs: To maintain water-tightness. Bridge decks and tunnels: To protect against water penetration. Swimming pools: To ensure a durable water seal. Installation Tips: Placement: It is installed in the construction joint or where two concrete surfaces meet. Positioning: Careful positioning within the formwork is crucial for ensuring its effectiveness. Sealing: After concrete is poured, the water stopper should be carefully checked to ensure there are no gaps or defects. Overall, PVC water stoppers are a reliable and efficient solution for preventing water damage in concrete structures exposed to water or moisture.

Color : Black Color

Application : Irrigation Project

Thickness : 8 Mm

Size : 500 Meter

Brand Name : SANDHYAFLEX

Material : Pvc

...more

Water Swellble Bar

170 - 200 Per Meter

A water swellable bar, also known as a waterstop bar or swellable waterstop, is a specialized construction material used in civil engineering and building construction to create watertight seals in concrete structures. Water swellable bars are designed to prevent the passage of water through joints, cracks, or construction gaps in concrete and to provide a reliable and durable waterproofing solution. These bars are particularly effective in situations where a continuous, flexible, and self-healing seal is required. Here are some key features and uses of water swellable bars: **Key Features:** 1. **Composition:** Water swellable bars are typically made from a combination of natural or synthetic rubber compounds and polymer materials that have the ability to absorb and swell upon contact with water. 2. **Profile:** They are often manufactured in the form of cylindrical bars or strips, which can be installed within construction joints, expansion joints, or around penetrations to create a watertight barrier. 3. **Swelling Properties:** The key feature of water swellable bars is their ability to absorb and swell when exposed to water. This swelling action helps to block water penetration and seal the joint or gap effectively. 4. **Self-Healing:** Water swellable bars have the ability to self-heal minor cracks or imperfections in the concrete over time. As they swell in the presence of water, they can close small openings and maintain the seal's integrity. 5. **Chemical Resistance:** They are often resistant to a range of chemicals, ensuring long-term performance and durability in various environments. **Uses:** Water swellable bars are used in a variety of construction applications to prevent water infiltration and create waterproof seals. Some common applications include: 1. **Construction Joints:** They are used to seal construction joints in concrete structures, such as foundation walls, basements, tunnels, and reservoirs, to prevent water from seeping through the joints. 2. **Expansion Joints:** Water swellable bars can be installed in expansion joints of bridges, buildings, and other structures to accommodate movement while maintaining a watertight seal. 3. **Pipe Penetrations:** They are used around pipe penetrations, such as water and sewer pipes, to create a waterproof seal where pipes pass through concrete walls or floors. 4. **Manholes and Sewers:** Water swellable bars can be used in manholes and sewer systems to prevent groundwater infiltration. 5. **Retaining Walls:** They are employed in retaining walls and dams to prevent water seepage through concrete joints and cracks. 6. **Tunnels and Underground Structures:** Water swellable bars are used to seal joints and connections in underground tunnels, subways, and other underground structures. 7. **Swimming Pools:** They are used to create watertight seals around joints and penetrations in swimming pool construction. Proper installation of water swellable bars is critical to their effectiveness. The bars should be installed according to manufacturer recommendations, ensuring that they are securely positioned within the joint or gap. Additionally, they should be protected from exposure to moisture during storage and handling to prevent premature swelling before installation. Regular inspections and maintenance may also be required to ensure the ongoing performance of the water swellable bars.

...more

Water Suction Discharge Rubber Hose

2,000 Per Meter

A water discharge rubber hose is a flexible, durable hose designed for transporting water or other liquids under low to medium pressure. These hoses are commonly used in construction, agriculture, mining, and industrial applications.

Brand Name : SANDHYA FLEX

Material : Nitrile Rubber,RUBBER

Finishing : Polished

Shape : Round

Color : Black

Pressure : High

Usage : Industrial Use

Certification : ISO 9001:2008

Size (Inches) : 3-12 INCHES

...more

Water Suction and Discharge Rubber Hose

3,300 - 6,000 Per Meter

A water suction and discharge rubber hose is a type of flexible hose designed for the suction and discharge of water and other fluids in various industrial, agricultural, and construction applications. These hoses are constructed from high-quality rubber or synthetic rubber compounds to withstand the rigors of fluid handling, and they are reinforced with layers of fabric, wire, or both to handle the pressure and vacuum requirements of the intended application. Here are some key features and uses of water suction and discharge rubber hoses: **Key Features:** 1. **Material:** Water suction and discharge hoses are typically made from natural rubber, synthetic rubber (such as EPDM or SBR), or a combination of rubber compounds that are compatible with the fluids being transported. 2. **Reinforcement:** To provide strength and durability, these hoses are reinforced with one or more layers of textile fabric, wire helix, or synthetic fibers. The choice of reinforcement depends on the specific application and working pressure requirements. 3. **Inner Lining:** The inner lining of the hose is usually smooth to facilitate the smooth flow of fluids and reduce friction losses. 4. **Outer Cover:** The outer cover is designed to protect the hose from abrasion, weathering, and environmental factors. 5. **Fittings and Connectors:** Water suction and discharge hoses are often equipped with a variety of fittings, couplings, or connectors at both ends to facilitate easy connections to pumps, valves, and other equipment. 6. **Size and Length:** These hoses come in various sizes and lengths to accommodate different flow rates and installation requirements. 7. **Temperature Range:** The hoses are engineered to handle a wide range of temperatures, making them suitable for both hot and cold water applications. **Uses:** Water suction and discharge rubber hoses find applications in a variety of industries and settings, including: 1. **Agriculture:** These hoses are used for irrigation, dewatering, and water transfer in agricultural operations, including farm equipment and crop irrigation systems. 2. **Construction:** They are employed in construction sites for dewatering excavations, transferring water, and controlling sediment. 3. **Mining:** Water suction and discharge hoses are used in mining operations for dewatering mines, transferring water, and handling slurry. 4. **Municipal Services:** They are used by municipal services for water supply and distribution, wastewater treatment, and emergency response situations. 5. **Industrial Processes:** These hoses are used in various industrial processes for fluid handling, including manufacturing, food processing, and chemical processing. 6. **Marine:** In marine applications, they are used for bilge pumping, ballast transfer, and other water-related tasks on ships and offshore platforms. 7. **Environmental Services:** Water suction and discharge hoses are used by environmental services for cleanup and removal of water, chemicals, and hazardous materials. 8. **Firefighting:** In firefighting operations, suction hoses are used to draw water from natural sources like lakes or ponds, while discharge hoses are used to deliver water to firefighting equipment. Proper selection, installation, and maintenance of water suction and discharge rubber hoses are crucial for their effective performance. Hoses should be chosen based on factors such as size, working pressure, temperature range, and compatibility with the fluids being transported. Regular inspections and replacement of hoses that show signs of wear, damage, or deterioration are essential to maintain system integrity and prevent leaks or disruptions during fluid transfer operations.

Brand Name : SNDHYAFLEX

Material : Rubber

...more

Water Stopper

160 - 450 Per Meter

500 Meter (MOQ)

Sandhya Enterprises are one of the top manufacturers in India. Water Stoppers are the flexible plastic strips that are used to provide a physical barrier to water. The barriers can be at concrete joints in basements, water-retaining structures like water tanks, swimming pools, structural foundations and other constructions of below ground level. Water stoppers are also known as water bars and seal construction joints. In a typical water stopper, there are two identical halves on both sides of the central bulb. They serve as an additional extension aiming to increase the path length for water entering behind the edge of water stopper. Compounding of PVC Water Stopper A PVC water stopper, also known as a PVC waterstop, is a type of construction material used to prevent water penetration in concrete structures, such as basements, swimming pools, water tanks, tunnels, and other areas where water containment is essential. It is designed to create a watertight seal and protect the integrity of the structure. Here are some key details and features related to PVC water stoppers: 1. Material: PVC water stoppers are made from high-quality polyvinyl chloride (PVC) material, which is known for its excellent durability, flexibility, and chemical resistance. PVC is resistant to water, chemicals, and environmental factors, making it suitable for use in various water containment applications. 2. Types: PVC water stoppers come in different types and profiles, depending on the specific application and requirements. Common types include straight PVC water stoppers, bulb-shaped water stoppers, ribbed water stoppers, and external water stoppers, among others. Each type has its unique design and features to cater to different sealing needs. 3. Design and Structure: PVC water stoppers are typically designed with a combination of rigid and flexible sections. The rigid sections provide stability and anchoring within the concrete structure, while the flexible sections allow for movement and accommodate joint expansion and contraction. 4. Installation: PVC water stoppers are usually installed during the concrete pouring process. They are placed within the construction joints or between the concrete sections to create a continuous barrier against water infiltration. The water stoppers are embedded into the concrete, forming a mechanical bond and ensuring a secure seal. 5. Sizes: PVC water stoppers are available in various sizes and dimensions to suit different joint widths and concrete thicknesses. The sizes can range from narrow profiles for smaller joints to wider profiles for larger joints. 6. Applications: PVC water stoppers are widely used in construction projects involving water containment. They are commonly utilized in structures such as basements, swimming pools, water treatment plants, dams, reservoirs, tunnels, and underground structures to prevent water leakage and maintain structural integrity. 7. Standards and Certifications: PVC water stoppers may adhere to industry standards and certifications, ensuring their quality and performance. Standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) may be applicable depending on the region and specific project requirements. When purchasing PVC water stoppers, it's important to consider factors such as the joint width, project specifications, and the specific application requirements. Consulting with a trusted supplier or manufacturer specialized in construction materials can help ensure you select the appropriate PVC water stopper for your specific project. Anti-ageing customized plastic compound is used for manufacturing the water stoppers. Alongside, it has PVC as a base polymer. Moreover, the properties it exhibit are high elasticity and tensile strength, immunity to corrosion, excellent weather resistance, unaffected by acids, alkalis, metals, salts and other chemicals. Other properties include lower wat

Material : Pvc

Color : Black, Blue, White

Application : Construction

Length : 25-30mtr

Type : Water Stopper, Pvc Water Stopper

Thickness : 6-8mm

Country of Origin : India

...more

water rubber hose

90 - 125 Per Meter

6 Meter (MOQ)

Water rubber hoses are flexible tubes made of rubber designed for the conveyance of water in various applications. These hoses are commonly used in industries, agriculture, construction, and households for tasks such as watering plants, irrigation, transferring water from one location to another, and more. Here are some key features and considerations related to water rubber hoses: **Key Features:** 1. **Material:** Water rubber hoses are typically made from synthetic rubber or a blend of natural and synthetic rubber materials. These materials provide flexibility, durability, and resistance to water-related conditions. 2. **Reinforcement:** Many water hoses have reinforcement layers, which may include textile braids or spirals, to enhance strength and prevent kinking. 3. **Flexibility:** Rubber hoses are known for their flexibility, allowing easy handling and maneuverability. 4. **Temperature Resistance:** Water rubber hoses are designed to withstand a range of temperatures, making them suitable for both hot and cold water applications. 5. **Weather Resistance:** They are resistant to weathering, UV rays, and ozone exposure, ensuring longevity in outdoor environments. 6. **Smooth Interior:** A smooth interior surface helps maintain efficient water flow by reducing friction and minimizing the chance of deposits forming inside the hose. 7. **Ease of Connection:** Water hoses often come with standard fittings for easy connection to water sources, faucets, or other water supply points. 8. **Variety of Sizes:** Water rubber hoses are available in various sizes to suit different applications and water flow requirements. **Common Uses:** 1. **Gardening:** Water rubber hoses are widely used for gardening purposes, including watering plants, lawns, and gardens. 2. **Irrigation:** In agriculture, these hoses are employed for irrigation systems to distribute water to crops. 3. **Construction:** On construction sites, water hoses are used for tasks such as dust suppression, concrete curing, and general water transport. 4. **Industrial Applications:** Water hoses are used in industrial settings for processes that involve the conveyance of water or other liquids. 5. **Domestic Use:** In households, water rubber hoses are used for washing cars, cleaning outdoor spaces, and various household chores. 6. **Firefighting:** Some water hoses are designed for firefighting applications, delivering water to control or extinguish fires. 7. **Municipal Utilities:** Municipalities use water hoses for various purposes, including water distribution and maintenance activities. **Maintenance Tips:** 1. **Regular Inspection:** Periodically inspect the hose for signs of wear, cuts, or damage. 2. **Proper Storage:** Store the hose away from direct sunlight and extreme temperatures to prolong its lifespan. 3. **Avoid Kinking:** Do not kink the hose during use, as this can lead to damage and restrict water flow. 4. **Drain After Use:** Drain the water from the hose after each use to prevent freezing in cold temperatures. 5. **Use Appropriate Fittings:** Ensure that the hose is equipped with fittings suitable for the intended use. Always follow the manufacturer's guidelines and recommendations for proper use and maintenance of water rubber hoses.

Material : Rubber

Color : Black

Condition : Used

Size : 4inch

...more

water barrier Nut

45 - 50 Per piece

As of my last knowledge update in September 2021, I am not aware of any specific product or ingredient called "Water Barrier Nut." However, if you're referring to a hypothetical or new product introduced after that date or if it's a specialized term used in a specific industry or context, I can provide some general information on how certain nuts and seeds can be used in culinary and industrial applications that involve water barriers. Nuts and seeds can be used in various ways to create water barriers or to address water-related issues in different applications: 1. Food Industry: - Nut Butters: Nuts like peanuts, almonds, and cashews can be ground into nut butters, which can be used as spreads or ingredients in recipes. They can also be used as thickeners in sauces, soups, and stews to create a creamy texture. 2. Baking: - Almond Flour: Ground almonds are often used in gluten-free baking as a substitute for traditional wheat flour. Almond flour can help absorb moisture and create a barrier in recipes. 3. Cooking: - Coating and Breading: Crushed nuts, like almonds or pistachios, can be used as coatings for meats or vegetables to create a crispy crust and prevent excess moisture absorption during frying. 4. Snacks: - Trail Mix: Nuts and seeds are common ingredients in trail mix, providing a combination of flavors and textures. Their natural oils can help create a barrier against moisture, keeping the mix fresh. 5. Industrial Applications: - Sealants and Barriers: Certain types of oils extracted from nuts and seeds can be used in industrial applications to create water-resistant or moisture-repellent barriers. These might include wood finishes, paints, and coatings. 6. Personal Care Products: - Cosmetics and Skincare: Some natural oils derived from nuts and seeds are used in cosmetics and skincare products to provide moisture barriers and skin protection. It's important to note that the specific use and application of nuts or nut-derived products can vary widely depending on the product or industry. If "Water Barrier Nut" refers to a specific product or concept introduced after my last update in September 2021, I recommend consulting the manufacturer's instructions or seeking more recent information for detailed guidance on its use. I'm not aware of a specific food item or ingredient called "Water Barrier Nut" in the context of common culinary knowledge up to September 2021. It's possible that this is a regional or specialized term or a new product introduced after my last knowledge update. If you have more context or information about what "Water Barrier Nut" refers to, please provide additional details, and I'll do my best to provide relevant information or assistance based on the information available up to my last update.

Shape : Square

Application : Road Safety

Pattern : Plain

Weight : 10-20 Kg

...more

w beam metal crash barrier

1,800 - 2,600 Per mtr

500 MTR (MOQ)

Country of Origin : India

Thickness : 20-40mm

Application : Highway

Color : Grey

Finishing : Polished

Material : Metal

Brand Name : SANDHYA FLEX

Condition : New

...more

VIP Floor Mat

550 - 750 Per piece

VIP Floor Mats typically refer to high-quality and often customized floor mats that are designed to enhance the aesthetics and comfort of a vehicle's interior, especially in luxury or high-end automobiles. These mats are commonly used in premium vehicles and are considered an accessory to improve the overall appearance and comfort of the car's interior. Here are some features and aspects of VIP floor mats: 1. **Materials:** VIP floor mats are typically made from premium materials such as high-quality carpeting, plush textiles, or even materials like leather or synthetic leather. These materials provide a luxurious and comfortable feel underfoot. 2. **Customization:** Many VIP floor mats can be customized to fit the specific make and model of the vehicle, allowing for a perfect fit. Customization options may include embroidery, personalized logos, or unique designs that match the vehicle's interior theme. 3. **Color and Design:** These mats often come in a variety of colors and designs to match or complement the interior color scheme of the vehicle. They may feature decorative patterns, trim accents, or contrasting stitching. 4. **Embellishments:** VIP floor mats may include additional embellishments such as metal emblems, decorative stitching, or branded logos to enhance their premium appearance. 5. **Durability:** While VIP floor mats prioritize aesthetics and comfort, they are typically designed to be durable and easy to clean. They should withstand normal wear and tear and resist staining. 6. **Anti-Slip Backing:** Many of these mats come with an anti-slip backing or fastening systems to keep them securely in place on the vehicle's floor. 7. **Sound Insulation:** Some VIP mats may have sound insulation properties to reduce road noise and enhance the vehicle's acoustic comfort. 8. **Ease of Maintenance:** Cleaning and maintaining VIP floor mats are relatively straightforward, and they can often be vacuumed, spot cleaned, or even removed for more thorough cleaning when necessary. VIP floor mats are not only functional but also contribute to the overall luxury and premium feel of a vehicle's interior. They are popular among car enthusiasts who want to personalize and upgrade their vehicles to match their style and preferences. While they may be more commonly associated with high-end and luxury vehicles, VIP floor mats can be added to various car models to elevate their interior aesthetics and comfort.

Brand Name : SNDHYAFLEX

...more

Vibration Screen Rubber Beading

125 - 135 Per Meter

Vibrating screen rubber beading, also known as screen sealing or screen gasket, is a specialized rubber component used in vibrating screens and sieving equipment. Its primary function is to provide a seal or cushioning between the screen panels or decks and the supporting frame. This rubber beading is designed to prevent material leakage, dampen vibrations, and ensure the efficient operation of the vibrating screen. Here are some key features and uses of vibrating screen rubber beading: **Key Features:** 1. **Material:** Vibrating screen rubber beading is typically made from high-quality rubber or elastomeric materials, such as natural rubber, neoprene, or silicone. The choice of material depends on factors like the application, temperature range, and chemical compatibility. 2. **Profile:** Rubber beading for vibrating screens often has a specific profile or shape, such as a U-shape or T-shape, to provide an effective seal and cushioning. 3. **Installation:** It is installed along the edges of the screen panels or decks, where it comes into contact with the frame or support structure. 4. **Durability:** The rubber beading is designed to be durable and resilient, with good resistance to wear and tear, as it is constantly subjected to vibrations and mechanical stress. 5. **Vibration Dampening:** It helps dampen vibrations generated by the vibrating screen, reducing the transmission of vibrations to the supporting structure. **Uses:** Vibrating screen rubber beading is used in various industries and applications, including: 1. **Screening and Sieving:** It is commonly used in vibrating screens and sieving equipment to seal and cushion the edges of screen panels or decks. 2. **Aggregate Processing:** In the mining and construction industries, vibrating screen rubber beading helps ensure efficient material screening and separation. 3. **Mineral Processing:** Vibrating screens are used in mineral processing plants to separate and classify ores and minerals, and the rubber beading helps maintain the integrity of the screen panels. 4. **Recycling:** It is used in recycling facilities for sorting and classifying materials like plastics, paper, and metals. 5. **Food Processing:** In food processing industries, vibrating screens are used for various tasks, including separating food products, and the rubber beading helps maintain hygiene standards. 6. **Pharmaceuticals:** Vibrating screens are used in pharmaceutical manufacturing for particle size classification and separation processes. 7. **Chemical and Petrochemical:** These industries use vibrating screens for various applications, such as separating chemicals, and the rubber beading ensures a reliable seal and cushioning. Proper installation and maintenance of vibrating screen rubber beading are essential to ensure its effectiveness and longevity. Periodic inspections should be conducted to check for wear, damage, or deterioration, and the rubber beading should be replaced as needed to maintain a proper seal and prevent material leakage. Additionally, selecting the right type of rubber beading based on the specific requirements of the vibrating screen and the materials being processed is crucial for optimal performance.

Brand Name : SNDHYAFLEX

Material : Natural Rubber

Color : Black

...more

Vibrating Screen Rubber Beading

115 Per Meter

200 Meter (MOQ)

Crusher mesh screen beading refers to the protective edging or reinforcement applied to the edges of a crusher screen mesh. This beading serves multiple purposes: Edge Protection – Prevents fraying or damage to the mesh screen edges. Structural Strength – Enhances the durability and longevity of the screen. Ease of Installation – Provides a stable edge for mounting and securing the screen onto the crusher frame. Vibration Resistance – Helps reduce wear and tear caused by constant vibrations and material impact. Types of Beading: Rubber Beading – Used to absorb shocks and vibrations, increasing screen life.

Brand Name : SANDHYA FLEX

Material : Neoprene

Color : Black

Certification : ISO 9001:2008 Certified

Hardness : 50-100

Type : Rubber Beading,u type

...more

Tyre Flaps

500 - 550 Per piece

A tire flap, often referred to simply as a "flap," is a rubber or synthetic material lining that is placed inside a tire to protect the inner tube from damage and to provide additional reinforcement to the tire. Flaps are commonly used in various types of pneumatic (air-filled) tires, particularly in commercial and heavy-duty vehicle tires. Here are some key points about tire flaps: 1. **Inner Tube Protection:** One of the primary functions of a tire flap is to protect the inner tube of the tire from being damaged by the rim or wheel components. Without a flap, the inner tube could be subjected to abrasions, punctures, or other types of damage caused by the sharp edges and irregularities of the rim. 2. **Reinforcement:** Tire flaps also serve as reinforcement for the area where the tire contacts the rim. This reinforcement helps distribute the stress and pressure more evenly, reducing the risk of damage to the tire. 3. **Material:** Tire flaps are typically made from rubber or synthetic materials that are resistant to wear, heat, and chemical exposure. They are designed to be durable and long-lasting. 4. **Installation:** Tire flaps are installed inside the tire, between the inner tube and the tire casing. They are positioned to cover the inner tube and extend to the area where the tire contacts the rim. 5. **Sizes:** Flaps come in various sizes to match different tire sizes and types. It's important to select the appropriate flap size to ensure proper fit and function. 6. **Tire Maintenance:** When tires are repaired or replaced, it is common practice to inspect the condition of the tire flap and replace it if it shows signs of wear, damage, or deterioration. 7. **Commercial and Heavy-Duty Use:** Tire flaps are particularly important in commercial and heavy-duty applications where the tires are subjected to greater loads, higher speeds, and more demanding conditions. Trucks, buses, construction equipment, and agricultural machinery often use tire flaps. In summary, a tire flap is an essential component of many pneumatic tires, especially in applications where durability and protection of the inner tube are critical. These flaps help extend the life of the tire and improve safety by preventing damage that could lead to sudden tire failures. Regular inspection and maintenance of tire flaps are important for safe and reliable operation.

Material : Rubber

Color : Black

Condition : New

...more

Transparent LDPE Sheet

180 - 2,000 Per Kilogram

low density polyethylene sheet has many names. It goes by the names poly sheeting, plastic sheeting, plastic film, polyethylene sheet, and poly film to name a few. polyethylene sheeting is a plastic film made from petroleum. That is why the price of the product can vary depending on what oil prices are doing. It is sold in rolls where in additives can be added to change the functionality of the film. additive such as u.v. Inhibitors, fire retardants, anti-static additives are added so each variation can best serve it’s intended use. ldpe plastic sheet, ldpe sheets mono industries were established in the year 2016 at Hyderabad, india. We are an iso 9001:2015 certified company and a reckoned name in the field of supplying a vast collection of ldpe sheet. We are specialized in offering an expansive range of ldpe plastic sheet to high standards. Our specialization is in supply hdpe sheet of 30 micron to 1000 microns and width of 1 meter to 6 meter. Our production procedures conform to is-2508/1984. Few application areas of our products are: LDPE (Low-Density Polyethylene) sheet is a versatile plastic material commonly used in various industries for its excellent flexibility, durability, and chemical resistance. LDPE is a thermoplastic polymer that is known for its low density, making it lightweight and easy to work with. Here are some key features and uses of LDPE sheets: 1. Material properties: LDPE sheets have excellent flexibility, allowing them to conform to irregular surfaces and withstand bending and stretching without cracking. They also exhibit good impact resistance, making them suitable for applications where impact or shock absorption is required. LDPE sheets are resistant to many chemicals, moisture, and UV radiation. 2. Versatility: LDPE sheets have a wide range of applications across different industries. They are commonly used for packaging materials, including bags, films, and wraps, due to their moisture resistance and sealing properties. LDPE sheets are also used in construction for vapor barriers, protective covers, and liners. Additionally, they are employed in agriculture for greenhouse films, pond liners, and irrigation systems. 3. Electrical insulation: LDPE sheets have excellent electrical insulation properties, making them suitable for applications in the electrical and electronics industry. They can be used as insulating barriers, gaskets, and components in electrical equipment. 4. Impact protection: The flexibility and shock-absorbing properties of LDPE sheets make them useful for impact protection applications. They can be employed as protective padding, bumpers, or liners to prevent damage to surfaces, equipment, or products. 5. Easy fabrication: LDPE sheets can be easily cut, formed, and welded using common fabrication techniques. They can be machined, drilled, or thermoformed to meet specific requirements. 6. Water and chemical resistance: LDPE sheets are highly resistant to water, moisture, and many chemicals. This makes them suitable for applications that involve exposure to liquids, such as chemical storage containers, water tanks, or lining for chemical processing equipment. 7. Food contact compliance: LDPE is commonly used for food packaging applications due to its low reactivity and compliance with food safety regulations. LDPE sheets that are designated as food-grade are safe for direct contact with food. It's important to note that LDPE has a lower temperature resistance compared to some other plastics. It begins to soften and deform at higher temperatures, limiting its suitability for applications involving high heat or prolonged exposure to sunlight. When considering LDPE sheets for a specific application, it is recommended to consult with suppliers or manufacturers who can provide guidance on material specifications, thickness options, and any additional requirements or certifications needed for your specific use case. LDPE (Low-Density Polyethylene) sheet is a

Type : Ldpe Plastic Sheet

Material : LDPE

Color : Black

Country of Origin : India

Condition : New

...more

Traffic Safety Cone

200 - 250 Per piece

A traffic safety cone, also known as a traffic cone, safety cone, or road cone, is a brightly colored, conical-shaped safety device typically made of rubber, plastic, or a combination of materials. These cones are commonly used in various traffic control, construction, and safety applications to alert and direct road users, pedestrians, and workers. Here are some key features and uses of traffic safety cones: 1. **Bright Color:** Traffic cones are usually bright orange, but they can also come in other high-visibility colors such as lime green or fluorescent red. The vivid color enhances visibility, especially in low-light conditions. 2. **Reflective Bands:** Many traffic cones have reflective bands or stripes that make them even more visible at night when illuminated by headlights or other light sources. 3. **Conical Shape:** The conical shape of these cones makes them easily stackable for storage and transportation. It also helps prevent them from being blown over by wind or displaced by vehicles. 4. **Multiple Sizes:** Traffic cones come in various sizes, with the most common ones being 18 inches (45 cm) and 28 inches (70 cm) in height. Smaller sizes are often used for pedestrian control, while larger ones are used on roadways. 5. **Versatile Applications:** - **Traffic Control:** They are commonly used to mark off lanes or sections of roads, indicate lane closures, and guide traffic around construction zones or accidents. - **Construction Sites:** Traffic cones are used to create a safe work zone and direct vehicles and pedestrians away from hazardous areas. - **Parking Lots:** They can be used to designate parking spaces, block off restricted areas, or indicate where vehicles should stop. - **Event Management:** Cones are used to control pedestrian and vehicle traffic during events, fairs, and parades. - **Safety Hazards:** Cones can be placed around hazards like potholes, damaged sidewalks, or fallen trees to alert people to potential dangers. 6. **Durable and Weather-Resistant:** Traffic cones are designed to withstand various weather conditions, including rain, snow, and UV exposure. They are typically made from materials that resist fading and damage. 7. **Portable and Easy to Handle:** Their lightweight construction makes traffic cones easy to transport and set up as needed. 8. **Compliance with Standards:** Traffic safety cones are often manufactured to comply with industry standards and regulations, ensuring their effectiveness in traffic and safety applications. When using traffic safety cones, it's important to follow best practices for placement and spacing to effectively manage traffic and safety hazards. Additionally, cones should be periodically inspected for damage and replaced when necessary to ensure their continued effectiveness in enhancing safety on the road and in various other settings.

Brand Name : SNDHYAFLEX

...more

Tie Rod Ends

110 - 115 Per Piece

A tie rod is a slender, long, threaded rod or bar with external threads on both ends, used to provide tension and structural support in a variety of applications, particularly in construction, mechanical engineering, and structural systems. Tie rods are a common structural component and serve several important purposes, such as: 1. **Structural Stability**: Tie rods are often used in construction and building structures to provide stability. They help prevent walls from spreading apart, which can be crucial for the overall integrity of a building. 2. **Tension Members**: Tie rods are tension members, meaning they are subjected to axial (tensile) forces. They are used to transfer loads and forces along their length. 3. **Vehicle Suspension**: In automotive and mechanical systems, tie rods are used in the suspension system to connect the steering knuckle to the steering gear. They help control the direction of the wheels and allow the vehicle to be steered. 4. **Mechanical Linkages**: In mechanical systems, tie rods can be used as part of linkages to transmit motion or force. They are often used in combination with other components like ball joints or bearings. 5. **Alignment and Adjustment**: Tie rods are used for alignment and adjustment purposes. In the case of vehicles, they can be adjusted to ensure proper wheel alignment. 6. **Load Distribution**: Tie rods can be used to distribute loads or forces evenly across a structure, such as in the case of truss systems or tension structures. 7. **Rigging and Tensioning**: Tie rods are used in rigging applications for tensioning purposes. They are commonly used in sailboat rigging to maintain tension in the rigging wires or cables. Tie rods come in various sizes, materials, and designs to suit different applications. They can be made of steel, stainless steel, or other materials depending on the requirements for strength and corrosion resistance. The ends of tie rods may be threaded, and they are often used in combination with nuts, clevises, or other connectors to secure them in place and allow for adjustments. In summary, tie rods are versatile structural elements used to provide tension, stability, and support in a wide range of applications, from building construction to mechanical systems and suspension systems in vehicles. Their design and material selection depend on the specific needs and forces they will encounter in their respective applications.

Brand Name : SNDHYAFLEX

...more

Tie Rod End

110 - 115 Per Number

A tie rod is a slender, long, threaded rod or bar with external threads on both ends, used to provide tension and structural support in a variety of applications, particularly in construction, mechanical engineering, and structural systems. Tie rods are a common structural component and serve several important purposes, such as: 1. **Structural Stability**: Tie rods are often used in construction and building structures to provide stability. They help prevent walls from spreading apart, which can be crucial for the overall integrity of a building. 2. **Tension Members**: Tie rods are tension members, meaning they are subjected to axial (tensile) forces. They are used to transfer loads and forces along their length. 3. **Vehicle Suspension**: In automotive and mechanical systems, tie rods are used in the suspension system to connect the steering knuckle to the steering gear. They help control the direction of the wheels and allow the vehicle to be steered. 4. **Mechanical Linkages**: In mechanical systems, tie rods can be used as part of linkages to transmit motion or force. They are often used in combination with other components like ball joints or bearings. 5. **Alignment and Adjustment**: Tie rods are used for alignment and adjustment purposes. In the case of vehicles, they can be adjusted to ensure proper wheel alignment. 6. **Load Distribution**: Tie rods can be used to distribute loads or forces evenly across a structure, such as in the case of truss systems or tension structures. 7. **Rigging and Tensioning**: Tie rods are used in rigging applications for tensioning purposes. They are commonly used in sailboat rigging to maintain tension in the rigging wires or cables. Tie rods come in various sizes, materials, and designs to suit different applications. They can be made of steel, stainless steel, or other materials depending on the requirements for strength and corrosion resistance. The ends of tie rods may be threaded, and they are often used in combination with nuts, clevises, or other connectors to secure them in place and allow for adjustments. In summary, tie rods are versatile structural elements used to provide tension, stability, and support in a wide range of applications, from building construction to mechanical systems and suspension systems in vehicles. Their design and material selection depend on the specific needs and forces they will encounter in their respective applications.

Brand Name : SNDHYAFLEX

...more

Tie Rod

110 - 120 Per Meter

A tie rod, also known as a tie-rod end or track rod, is a crucial component of a vehicle's steering system. It plays a significant role in maintaining proper steering control and alignment. Tie rods are found in both traditional (non-rack-and-pinion) and rack-and-pinion steering systems, although the design and placement may vary. Here are the main functions and components of a tie rod: 1. **Steering Linkage:** Tie rods are part of the steering linkage that connects the steering gear (or steering rack in rack-and-pinion systems) to the steering knuckles of the front wheels. 2. **Steering Control:** When you turn the steering wheel, it causes the tie rods to pivot and transfer that motion to the front wheels. This is how you control the direction of your vehicle. 3. **Alignment:** Tie rods also play a crucial role in maintaining proper wheel alignment. They help ensure that the wheels are aligned parallel to each other and perpendicular to the road surface. Proper alignment is essential for safe and predictable handling and to prevent uneven tire wear. There are two main types of tie rods: 1. **Inner Tie Rod:** This part connects to the steering gear or rack and is typically threaded into it. The inner tie rod is hidden beneath a boot to protect it from dirt and debris. 2. **Outer Tie Rod:** The outer tie rod connects to the inner tie rod on one end and the steering knuckle on the other end. It's the part of the tie rod that is more exposed and easier to access. Tie rods are adjustable to some extent to allow for precise alignment of the wheels. When tie rods wear out or become damaged, it can result in steering problems, including poor handling, uneven tire wear, and alignment issues. Regular maintenance and inspections are important to ensure that tie rods are in good condition and that your vehicle's steering system functions correctly. If you suspect an issue with your tie rods, it's essential to have them inspected and replaced if necessary to maintain safe and effective steering control. Improperly functioning tie rods can compromise the safety and performance of your vehicle.

Brand Name : SNDHYAFLEX

...more

textile braided rubber hose

110 Per Meter

100 Meter (MOQ)

Type : Spray Hose Pipe

Brand Name : SANDHYAFLEX

Material : Rubber And Yarn

Shape : Round

Color : Black

Pressure : 10Bar

Tensile Strength : 7MPa

Hardness : 55-65

Working Pressure : 10MPa

...moreOpening Hours