Wastewater Treatment Equipment

Get Price Quote

Our quality products have made us the leading manufacturer, exporter and supplier of high quality Waste Water Treatment Plants Equipments, Sewage Treatment Plants Equipments, Effluent Treatment Plants Equipments, Mineral Water Treatment Plants Equipments, MBBR Media, Bio PAC Media, (Fab Media), Tubesettler (Hexagonal) Shape, Wheel Media, Fill PAC Media, Bio PAC Media, and various others. Our qualitative range has earned an envious reputation over the years in the market. We have very sufficient work force. Our production type is both Fully automatic that provides us flexibility to accomplish more than 1 crore sales volume.

Mechanical Bar Screen

Get Price Quote

1 Piece (MOQ)

Rake screens of various measurements are made of stainless steel AISI 304 or AISI 316 on customer demand. Measurements of the rake screens are chosen relying upon required flow rate, wastewater arrangement and measurements of the channels. The rake screen is a separating mesh comprising of bars introduced into a frame. The bars are produced using primary shapes with a tear drop formed cross segment that improves stream attributes of the filtering mesh. The screen’s filtering mesh can also be made of rectangular or round profile bars. Bar dispersing in the filtering mesh can change from 5 – 100mm for normal hardware or can be changed exclusively. The rectangular edge comprises of two longitudinal sheets associated by cross shafts. The covered hardened steel chains can be moved along polymer guides installed on the longitudinal sheets of the screen. Chain strain is movable. Cross rakes are introduced on the chains for cleaning of the filtering mesh. Chains and rakes are impelled by shaft rotation with drive sprockets situated in the screen top segment. The shaft is driven by a motor. At the screen base, the chain is moved along a pilot slider made of a wear safe polymer material. In this way, there are no pivoting parts in the lowered segment of the screen. The screen is introduced onto a hub of an extraordinary turning prop mounted on the wall of the channel or onto unique stage affixed in the channel while the actual screen can be lifted over the channel for upkeep. In the event that there is an absence of room in a short station without probability of screen lifting, an extraordinary adaptive stage is utilized Operating Principal The rake screen gathers and eliminates solids from wastewater that bigger than bar separating. The solids are regularly taken off from the sifting network by the rake moving them to the top edge of the edge. The solids are then eliminated from the rake by methods for a kicker and dispatched along the gravity slide onto a carrier or into squander container. The screen operation periodicity depends on the chosen equipment automation scheme and defined by technological commission results. Advantages of Bar Screen: Protection from mechanical and pressure-driven over-burdens because of high tensile design in correlation with different kinds of mechanized screens High hydraulic efficiency is achieved by using tear-shaped bars that cause a pressure gradient to the mesh and across the bar spacing The tear molded profile also shields the screen from waste sticking inside the filtering mesh. By utilizing this plan, such blockages can be eliminated by rakes, permitting the screen work uninhibitedly; High dependability, accomplished by the shortfall of the turning parts in the submersible part Submersible parts like packaging, bars, chains and rakes are made of tempered steel to improve consumption obstruction in forceful conditions of wastewater; Improved ergonomics: the practicality of the screen because of openness of the principle units inactivity and screen lifting without demounting. Automation : Screen automation is possible as per various boundaries: Timespan. Wastewater level contrast upstream and downstream of the screen. Any modified program. Alert frameworks are accommodated the typical activity sign, the crisis stops, the wastewater high level in the channel and others. It is conceivable to move gear status information to a more significant level automated process control framework relying upon the customer’s necessities. The screen is provided with a security device jet lever to evade harm to the screen, for example, chain extending or breaking. The security gadget and stops the screen activity in case of any jam or mechanical hindrance to the chain development. Light and sound alerts turn on all the while when the safety device activates. The screens along with a conveyer, compacting press and slide doors are remembered for an elite complex for mechanical wastewater treatment. Outfitting the control system with programmable modules makes it conceivable to coordinate complex sub systems into one system with a common control centre and remote dispatching.

Best Deals from Sewage Treatment Equipment

High Speed Stirrer

12,000 Per Piece

10 Piece (MOQ)

Vacuum Evaporator

Get Price Quote

Vacuum evaporator are suitable for automatic, standard, and complex distillation. We have developed our evaporators keeping in mind the convenience, safety, and running-cost.

STP-DN 19-25-32 Manual Steel Strapping Tool with Seal

Get Price Quote

1 Pieces (MOQ)

Water Treatment Equipment (wte - 01)

Get Price Quote

We are offering water treatment equipment.

High Speed Stirrer

Get Price Quote

We are the main supplier of this product.

High Speed Stirrer

Get Price Quote

Intelligent Evaporation Intelligent evaporation stands for an overheat protection design that prevents water baths running dry, a detachable panel for superior ease of use from outside closed fume hoods and offers a proven vacuum seal and vapor tube system guaranteed for years of operation!

Rotary Vacuum Evaporator

Get Price Quote

vacuum rotary evaporator

Get Price Quote

Multi Rake Screen

Get Price Quote

vacuum rotary evaporator

78,000 Per Unit

Digital Water Flow Meter

Get Price Quote

Model No :: BT PHTFS D - Digital water meter Product Specification :: Helical rotor Positive displacement base DIGITAL WATER FLOW METER developed by "BROILTECH" indiginiously first time in world for water industries, Helical rotor Digital Water Meter design is proven for best accuracy and low pressure loss than turbine and oval gear, so customer got more flow rate and low power consumption, its also not effected on viscosity of liquied and temp. change.its also use for various liquied flow measurement from low to high viscousitydigital water flow meter technical specification:Model No : BT- PHTFS-D Manufacturer : BROILTECH Material of construction: Enclosure : PA66 + GF Rotor : PA66/POM/PPS Shaft : Hard Stainless Steel-316 bearing : carbon/pom with hard S.S. BALL Accuracy (standard installation position) : +/- 0.5 or 1% FSD Repeatability : 0.05% Maximum working pressure : 2.5 MPa Fluid &Ambient temperature: -40 to 120 Deg. C Connection: Thread (M) 1) Battery operated meter : Power voltage: 3.0 Vbatteries can be used more than 1 years in a row. display mode: Double row Liquid Crystal Display (LCD), as follows: L XXX. X four instantaneous flow (m3 / h) or L/h L XXXX. X Partial total (m3 / h) or L/h XXXXX.X*100 eight cumulative flow (m3) or L XXXXX.X*100 eight cumulative flow (m3) or L( never reset total) Cumulative flow: automatically expand the display precision, the cumulative flow/partial values can be reset. Power-fail protection: instrument coefficient, the Total flow values ten years is not lost when power supply drop. 2) Display with 4 to 20 mA Output Power voltage: 24 V DC Output signal: 4 TO 20 mA Helical flow Meter model no wise Technical data: Model no Connection(M) Range BT-PHTFS-004 1/4 BSP 5~40~400 L/H BT-PHTFS-008 1/2 BSP 10~150~1500 L/H BT-PHTFS-012 3/4BSP 50~500~5000 L/H BT-PHTFS-020 1” BSP 80~8000~8000 L/H BT-PHTFS-025 1.25” BSP 100~1000~10000 L/H BT-DFS-600 40 mm --1.5” Thread 7~2,00L/H BT-DFS-700 50 mm --2” Thread 10~500L/H Product Features :: digital water flow meter is best economical solution of water consumption measurement at industrial and residential application, digital water flow meter available with battery operated display plus optional pulse output for water billing system and WATER AMR application Range :: Helical rotor digital water flow meter is best for bellow appliction : Applications: : Very good for WATER ATM, water dispensing, tea/coffee/wine/juice and other food liquid measurement and dispensing, : Polyurethane and polymer : Light and heavy fuel oil : Petrochemical products: Thixotropical fluids : Fat and oils with varying viscosities : Test rigs with varying viscosities and fluids : Water / glycol mixtures: Crude oil, furnace oil, and all viscous liquid even viscosity change with Temperature Product Applications :: Pure Water Fuel Oil High Viscosity Liquid Heat/BTU Hygienic Liquid

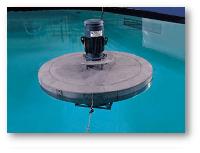

AIRE-O2 Turbo Surface Aerator

Get Price Quote

Superior to other surface splashers no gear box low operating costs less aerosols & voc emissions.

Sewage Treatment Equipment

Get Price Quote

Sewage Treatment Equipment, Sewage Water Treatment Plant

Wastewater Treatment Equipment

Get Price Quote

Wastewater Treatment Equipment, Industrial Reverse Osmosis System

Waste Water Treatment Equipment

Get Price Quote

Waste Water Treatment Equipment, Water Treatment System

surface aerators

Get Price Quote

surface aerators

Mechanical Bar Screen

Get Price Quote

Sequential Batch Reactor, disc diffusers

Waste Water Treatment Equipment

Get Price Quote

Waste Water Treatment Equipment, Water Treatment, Waste Water Treatment