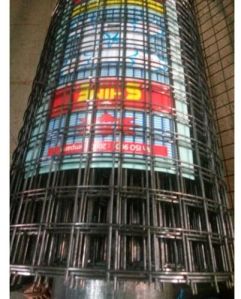

Welded Wire Mesh Wire Netting

60 Per Kilogram

Material : SS316

Type : Welded Wire Mesh

Color : Silver

...more

Ungalvanized Wire Mesh

Application : Industrial

Material : Fine SS

Surface Treatment : Polished

Wire Gauge : 3mm

Color : Black

...more

Perforated Sheet

We offer perforated sheets by using qualitative raw material and thickness ranges from 1 mm to 2mm.We deal with different types of sheets in HR and GI that arewidely used in filter industries, furniture, diesel generator companies, food industry, automobiles, engineering industries, electronics and agricultural tools

...more

oil tempered spring wire

Applications Cooler Grill Poultry Cages Poultry Farms Concrete Pipes Over Head Tanks Cellular Towers Fencing of any area Concrete Road and Reinforcement Industrial & commercial flooring We offer a wide range of weld mesh, which possess high strength, rigidity and resistance to corrosion. These welds help in keeping the wires straight, uniform and distortion-free without risk of fraying. This is mainly used for fencing and concrete reinforcement. WELDED WIRE MESH (WWM) AND WELDED WIRE FABRIC (WWF) Manufacturing process: Wire mesh is prefabricated to rectangular or square steel mesh consisting of series of parallel, longitudinal, cold-worked high-yield steel wires welded at regular intervals to transverse wires. Wire mesh is manufactured on automatic welding machines, ensuring uniform spacing of wires and consistent cross-sectional areas. The welding is accomplished by an electronically controlled electrical process employing the principle of fusion combined with pressure, which actually fuses the intersecting wires into homogeneous section without loss of strength. The welds in plain cold-worked Wires contribute to the bonding and anchorage values in concrete. MATERIALS; The wires used in the fabric are cold drawn from mild steel wire rods and are manufactured conforming to IS;432-PTII/ 1982 WWF is manufactured conforming to IS;1566/1982 APPLICATIONS; WELD FENCE; WWM offers a convenient means to quickly partition/ barricade large areas with rigid fencing. It is also used as guard for trees, machines and electrical equipment. FLOOR GRATINGS; WWM is an easier alternative to plates for industrial structural flooring. It provides for lighter material and ventilation across floors. WELDED WIRE GABIONS; Gabions are heavy duty rectangular wire mesh filled with rock or rubble to economically And effectively construct earth retaining walls and erosion control structures

...more

Galvanized Steel Wire

We also manufacture the galvanized steel wires which are been used making wire ropes and various types of springs. The range available with us is from 0.17mm to 1.3mm, weights from 20—50 kgs. We supply these wires in the bundles and these wires are zinc coated and galvanized .

...more

Galvanised Concertina Coil Wire

Surface Treatment : Galvanised

Gabion Box

Gabions, Mattresses and Rock Netting products are available in the following specificationsTriple Life Coatings (95% Zinc 5% Aluminium) For non aggressive applications:Retaining structures in non aggresive environments.Fresh water applications.Cladding of structures.Free Standing WallsGabion FencingRock Fall protectionPVC-Zinc Coatings For structures in aggressive applications:Saline water Environments.Retaining structures subject to salt spray.Landfill structure.Rockfall protection.Stainless Steel For structures in aggressive applications or for architectural structures.

...more

Expanded Plate Mesh

Material: Superior steel material Processing: Expanded with steel or other metals Features: Durable, strong an Material: Superior steel material Processing: Expanded with steel or other metals Features: Durable, strong and beautiful. Application: Expanded metal is mainly used in microphone, filter elements, construction, bridge, platform and fencing or guarding materials for machinery Hexagonal Wire Mesh Hexagonal Wire Netting is extensively used in building as reinforcement of the roof and floor, it is also used as fence for poultry cage, fish garden and children playground. Hexagonal Wire Netting is also named Chicken netting due to its application as fences for chicken and other animal d beautiful. Application: Expanded metal is mainly used in microphone, filter elements, construction, bridge, platform and fencing or guarding materials for machinery Hexagonal Wire Netting is extensively used in building as reinforcement of the roof and floor, it is also used as fence for poultry cage, fish garden and children playground. Hexagonal Wire Netting is also named Chicken netting due to its application as fences for chicken and other animals.

...more

Crimped Mesh

Generally made out of low carbon steel, galvanized steel wire or stainless steel wire, crimped wiremesh is again a common feature of industries where sieving is prevalent. The screens are generally employed in series in order to generate and separate the finest of particles of chemicals, fertilizers and pharmaceuticals. Boasting of service to all the top industries in the related fields in India, we now look forward to enter the global market with our specialized product range. Product range: 1" - 1/4" square (In desired width and length) Wire diameter: 6.00mm - 1.2mm Metal: M.S, G-1, Stainless Steel, Copper, Brass, Carbon steel, etcEnd use: Filtering, Sizing, Grading, Separating, Shifting and Domestic use as Grid window, Rack, Lift, Cages, Guards, Trays, Partitions and many other Industrial useIndustries : Chemical, Pharmaceutical, Fertilizers, Sugar, Cement, Celluloid, and Marine engineering applications

...more

Corner Bead

Corner Bead provides a straight arris that will not easily crack and reinforces the plaster where it is most required. The expanded mesh wings of angle bead provide an excellent mechanical key for most types of plaster and render. Corner bead is simple and quick to fit. Plaster dabs are applied to the wall at 600mm spacing and the wings of the bead then pressed into the plaster dabs to plumb or level the bead. Where the corner bead has to be fixed to metal lath it is recommended that it is fixed with wire ties. When cutting is required this should be carried out by using a fine toothed hacksaw on the solid metal and tinsnips on the mesh wings. To join two lengths together a headless nail should be used to ensure alignment of the nose.

...more

Concertina Coil

Concertina coil is product which is revolutionary concept which successfully replaces the conventional barbed wire, making it obsolete owning to their multiple advantages over the later. Concertina Coil for Military Application Concertina Coil is the perfect barrier for the Military applications. Concertina wire can be stored in a compact condition ready for use. It is difficult to breach providing troops and equipment with high levels of security. Concertina Coil Perimeter Security Concertina Coil is one of the most effective ways of securing any size of perimeter. It is cost effective and extremely versatile, it can be installed in a variety of configurations and on virtually any terrain. Concertina Coil Mobile Security Barriers The Concertina Coil mobile security barriers are the fastest most reliable portable security systems! Up to a thousand meters of pre-formed pyramid barriers may be deployed from a single trailer in a few minutes. The barrier is used effectively through out the world to uphold control and provide security in numerous situations. The coil can be recollected with little effort using the purpose designed mechanical collection system. Concertina Coil for Civilian Application Concertina Coil is the ideal fence to improve security at homes, schools, offices and factories. It can be used on its own or used to embellish a pre-standing wall or fence. Concertina Coil for Prison Application Concertina Coil is commonly used to secure prisons. It is almost impossible to breach concertina coil without specialized equipments. Concertina Coil for Boarder Security Concertina Coil can be used to secure extensive areas at a fraction of the cost of other systems. It can also be incorporated with monitoring or electric system for extra security.

...more

Chain Link Mesh

We offer our range of chainlink fencing in G.I, PVC coated and stainless steel construction. Our range is available in 6SWG TO 18SWG and various specifications of height, length, width and sizes. These entire specifications can be customized as per the client's specifications. A chain-link fence or wire netting or chain-wire fence is a type of woven fence usually made from galvanized or LLDPE-coated steel wire. The wires run vertically and are bent into a zig-zag pattern so that each "zig" hooks with the wire immediately on one side and each "zag" with the wire immediately on the other. This forms the characteristic diamond pattern seen in this type of fence. Fencing usually comes in 20 rod and 50 ft rolls which can be joined by "unscrewing" one of the end wires and then "screwing" it back in so that it hooks both pieces. Common heights include 3 ft, 3 ft 6 in, 4 ft, 5 ft, 6 ft, 7 ft, 8 ft, 10 ft, and 12 ft, though almost any height is possible. Common mesh gauges are 9, 11, and 11.5. For tennis courts and ball parks the most popular height is 9 ft (2.75 m). The popularity of chain-link fence is due to its relatively low cost and ease of installation. A further advantage is that due to the open weave, chain-link fences are transparent, and do not obscure sunlight from either side of the fence. If a semi-opaque fence is desired, this can be achieved by the insertion of slats into the mesh.

...more

Barbed Wire

Barbed wire, also known as barb wire (and frequently in dialect form spelled bob or bobbed), is a type of fencing wireconstructed with sharp edges or points arranged at intervals along the strand(s). It is used to construct inexpensive fences and is used atop walls surrounding secured property. It is also a major feature of the fortifications in trench warfare (as a wire obstacle). A person or animal trying to pass through or over barbed wire will suffer discomfort and possibly injury. Barbed wire fencing requires only fence posts, wire and fixing devices such as staples. It is simple to construct and quick to erect by an unskilled person. It was first conceived in 1865 by Louis Jannin as fil de fer barbelé, French for "barbed iron wire". Joseph F. Glidden ofDeKalb, Illinois received a patent for the modern invention in 1874. Barbed wire was the first wire technology capable of restraining cattle. Wire fences were cheaper to erect than their alternatives and when they became widely available in the United States in the late 19th century they made it affordable to fence much larger areas than before. They made intensive animal husbandry practical on a much larger scale. The most important and most time-consuming part of a barbed wire fence is constructing the corner post and the bracing assembly. A barbed wire fence is under tremendous tension, often up to half a ton, and so the corner post's sole function is to resist the tension of the fence spans connected to it. The bracing keeps the corner post vertical and prevents slack from developing in the fence. Brace posts are placed in-line about 8 feet (2.4 m) from the corner post. A horizontal compression brace connects the top of the two posts, and a diagonal wire connects the top of the brace post to the bottom of the corner post. This diagonal wire prevents the brace post from leaning, which in turn allows the horizontal brace to prevent the corner post from leaning into the brace post. A second set of brace posts (forming a double brace) is used whenever the barbed wire span exceeds 200 feet (60 m). If an 8" post is * feet in length is driven four feet into the ground the brace post assembly can be omitted. When the barbed wire span exceeds 650 ft (200 m), a braced line assembly is added in-line. This has the function of a corner post and brace assembly but handles tension from opposite sides. It uses diagonal brace wire that connects the tops to the bottoms of all adjacent posts. Line posts are installed along the span of the fence at intervals of 8 to 50 ft (2.5 m to 15 m). An interval of 16 ft (5 m) is most common. Heavy livestock and crowded pasture demands the smaller spacing. The sole function of a line post is not to take up slack but to keep the barbed wire strands spaced equally and off the ground. Once these posts and bracing have been erected, the wire is wrapped around one corner post, held with a hitch (a timber hitch works well for this) often using a staple to hold the height and then reeled out along the span of the fence replacing the role every 400 m . It is then wrapped around the opposite corner post, pulled tightly with wire stretchers, and sometimes nailed with more fence staples, although this may make readjustment of tension or replacement of the wire more difficult. Then it is attached to all of the line posts with fencing staples driven in partially to allow stretching of the wire. It is installed from the top down. There are several ways to anchor the wire to a corner post: Hand-knotting. The wire is wrapped around the corner post and knotted by hand. This is the most common method to attaching wire to a corner post. A timber hitch works well as it stays better with wire than with rope. Crimp sleeves. The wire is wrapped around the corner post and bound to the incoming wire using metal sleeves which are crimped using lock cutters. This method should be avoided because while sleeves can work well on repairs in the middle of the fence where there is not enough wire for hand knotting, they tend to slip when under tension. Wire vise. The wire is passed through a hole drilled into the corner post and is anchored on the far side. Wire wrap. The wire is wrapped around the corner post and wrapped onto a special, gritted helical wire which also wraps around the incoming wire, with friction holding it in place. Barbed wire for agriculture use is typically double-strand 12½-gauge, zinc-coated (galvanized) steel and comes in rolls of 1320 ft (402 m) length. Barbed wire is usually placed on the inner (pasture) side of the posts. Where a fence runs between two pastures livestock could be with the wire on the outside or on both sides of the fence. Galvanized wire is classified into three categories; Classes I, II, and III. Class I has the thinnest coating and the shortest life expectancy. A wire with Class I coating will start showing general rusting in 8 to 10 years, while the same wire with Class III coating will show rust in 15 to 20 years. Aluminum-coated wire is occasionally used, and yields a longer life. Corner posts are 6 to 8 inches (15 to 20 cm) in diameter or larger, and a minimum 8 feet (2.4 m) in length may consist of treated wood or from durable on-site trees such as osage orange, black locust, red cedar, or red mulberry, also railroad ties, telephone, and power poles are salvaged to be used as corner posts(poles and railroad ties were often treated with chemicals determined to be an environmental hazard and cannot be reused in some jurisdictions). In Canada spruce posts are sold for this purpose. Posts are driven at least 4 feet (1.2 m) and may be anchored in a concrete base 20 inches (50 cm) square and 42 inches (105 cm) deep. Brace posts are a minimum 4 inches (10 cm) in diameter and are anchored in a concrete base 20 inches (50 cm) square and 24 inches (60 cm) deep. Iron posts, if used, are a minimum 2½ inch (64 mm) in diameter. Bracing wire is typically smooth 9-gauge. Line posts are set to a depth of about 30 inches (75 cm). The main advantage of steel posts is that they can be driven with a post moll or a cylindrical tube closed at one end with plate steel for weight, and pulled out by hand as opposed to wooden posts which must be pounded with a hydraulic pounder and often pulled with a front end loader. Conversely steel posts are not as stiff as wood and wires are fastened with slips along fixed teeth which means variations in driving height effect wire spacing. During the First World War, screw pickets were used for the installation of wire obstacles; these were metal rods with eyelets for holding strands of wire, and a corkscrew-like end that could literally be screwed into the ground rather than hammered, so that wiring parties could work at night near enemy soldiers and not reveal their position by the sound of hammers.Barbed wire, also known as barb wire (and frequently in dialect form spelled bob or bobbed), is a type of fencing wireconstructed with sharp edges or points arranged at intervals along the strand(s). It is used to construct inexpensive fences and is used atop walls surrounding secured property. It is also a major feature of the fortifications in trench warfare (as a wire obstacle). A person or animal trying to pass through or over barbed wire will suffer discomfort and possibly injury. Barbed wire fencing requires only fence posts, wire and fixing devices such as staples. It is simple to construct and quick to erect by an unskilled person. It was first conceived in 1865 by Louis Jannin as fil de fer barbelé, French for "barbed iron wire". Joseph F. Glidden ofDeKalb, Illinois received a patent for the modern invention in 1874. Barbed wire was the first wire technology capable of restraining cattle. Wire fences were cheaper to erect than their alternatives and when they became widely available in the United States in the late 19th century they made it affordable to fence much larger areas than before. They made intensive animal husbandry practical on a much larger scale. The most important and most time-consuming part of a barbed wire fence is constructing the corner post and the bracing assembly. A barbed wire fence is under tremendous tension, often up to half a ton, and so the corner post's sole function is to resist the tension of the fence spans connected to it. The bracing keeps the corner post vertical and prevents slack from developing in the fence. Brace posts are placed in-line about 8 feet (2.4 m) from the corner post. A horizontal compression brace connects the top of the two posts, and a diagonal wire connects the top of the brace post to the bottom of the corner post. This diagonal wire prevents the brace post from leaning, which in turn allows the horizontal brace to prevent the corner post from leaning into the brace post. A second set of brace posts (forming a double brace) is used whenever the barbed wire span exceeds 200 feet (60 m). If an 8" post is * feet in length is driven four feet into the ground the brace post assembly can be omitted. When the barbed wire span exceeds 650 ft (200 m), a braced line assembly is added in-line. This has the function of a corner post and brace assembly but handles tension from opposite sides. It uses diagonal brace wire that connects the tops to the bottoms of all adjacent posts. Line posts are installed along the span of the fence at intervals of 8 to 50 ft (2.5 m to 15 m). An interval of 16 ft (5 m) is most common. Heavy livestock and crowded pasture demands the smaller spacing. The sole function of a line post is not to take up slack but to keep the barbed wire strands spaced equally and off the ground. Once these posts and bracing have been erected, the wire is wrapped around one corner post, held with a hitch (a timber hitch works well for this) often using a staple to hold the height and then reeled out along the span of the fence replacing the role every 400 m . It is then wrapped around the opposite corner post, pulled tightly with wire stretchers, and sometimes nailed with more fence staples, although this may make readjustment of tension or replacement of the wire more difficult. Then it is attached to all of the line posts with fencing staples driven in partially to allow stretching of the wire. It is installed from the top down. There are several ways to anchor the wire to a corner post: Hand-knotting. The wire is wrapped around the corner post and knotted by hand. This is the most common method to attaching wire to a corner post. A timber hitch works well as it stays better with wire than with rope. Crimp sleeves. The wire is wrapped around the corner post and bound to the incoming wire using metal sleeves which are crimped using lock cutters. This method should be avoided because while sleeves can work well on repairs in the middle of the fence where there is not enough wire for hand knotting, they tend to slip when under tension. Wire vise. The wire is passed through a hole drilled into the corner post and is anchored on the far side. Wire wrap. The wire is wrapped around the corner post and wrapped onto a special, gritted helical wire which also wraps around the incoming wire, with friction holding it in place. Barbed wire for agriculture use is typically double-strand 12½-gauge, zinc-coated (galvanized) steel and comes in rolls of 1320 ft (402 m) length. Barbed wire is usually placed on the inner (pasture) side of the posts. Where a fence runs between two pastures livestock could be with the wire on the outside or on both sides of the fence. Galvanized wire is classified into three categories; Classes I, II, and III. Class I has the thinnest coating and the shortest life expectancy. A wire with Class I coating will start showing general rusting in 8 to 10 years, while the same wire with Class III coating will show rust in 15 to 20 years. Aluminum-coated wire is occasionally used, and yields a longer life. Corner posts are 6 to 8 inches (15 to 20 cm) in diameter or larger, and a minimum 8 feet (2.4 m) in length may consist of treated wood or from durable on-site trees such as osage orange, black locust, red cedar, or red mulberry, also railroad ties, telephone, and power poles are salvaged to be used as corner posts(poles and railroad ties were often treated with chemicals determined to be an environmental hazard and cannot be reused in some jurisdictions). In Canada spruce posts are sold for this purpose. Posts are driven at least 4 feet (1.2 m) and may be anchored in a concrete base 20 inches (50 cm) square and 42 inches (105 cm) deep. Brace posts are a minimum 4 inches (10 cm) in diameter and are anchored in a concrete base 20 inches (50 cm) square and 24 inches (60 cm) deep. Iron posts, if used, are a minimum 2½ inch (64 mm) in diameter. Bracing wire is typically smooth 9-gauge. Line posts are set to a depth of about 30 inches (75 cm). The main advantage of steel posts is that they can be driven with a post moll or a cylindrical tube closed at one end with plate steel for weight, and pulled out by hand as opposed to wooden posts which must be pounded with a hydraulic pounder and often pulled with a front end loader. Conversely steel posts are not as stiff as wood and wires are fastened with slips along fixed teeth which means variations in driving height effect wire spacing. During the First World War, screw pickets were used for the installation of wire obstacles; these were metal rods with eyelets for holding strands of wire, and a corkscrew-like end that could literally be screwed into the ground rather than hammered, so that wiring parties could work at night near enemy soldiers and not reveal their position by the sound of hammers.

...moreBe first to Rate

Rate ThisOpening Hours