Coconut Dehusking Machine

280,000 Per Piece

1 Piece (MOQ)

Features : Free from maintenance Easy to operate Removes the husk of any size coconut High Productivity Less Man power Economic

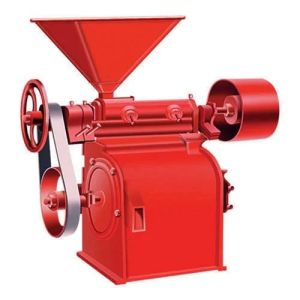

rice husker

Get Price Quote

We understand that superior-grade raw materials are essential for the production of quality products. Thus, we maintain cordial association with reliable vendors of the market. Our warehouse is well constructed and equipped with all required amenities essential for a safe storage of the products. We also make sure that proper hygienic conditions should be maintained inside the unit. What this Machine Does for You ?It Aspirates the Husk from the Mixure of Unshelled Paddy, Brown Rice and Husk Comming Out from Rubber Roll Sheller.

Best Deals from Husking Machine

sunflower seed sheller

55,000 - 56,000 Per piece

The sunflower seed sheller is the most advanced machine used in sunflower seed processing units. The machine is used for pre-cleaning, de-hulling, peeling, sorting, and checking. THOMAS INTERNATIONAL is the right place to get the best quality sunflower seed shellers. Thomas International is a reliable and trusted supplier of sunflower seed shellers. A Seed processing plant splits the natural product which comes from fields from the lean harvest. It also calibrates the product with desired sizes and processes 10 tons/hour input product with %95-97 purity. Whereby using Fotosorter (Color-sorter) output purity can reach up to %99.9. THOMAS INTERNATIONAL is a leading sunflower seed sheller manufacturer and has a state-of-the-art manufacturing facility. Our production unit is equipped with high-tech machines and necessary technology that provide better flexibility to the entire process and ensures cost-effective production and precision in our products. Sunflower seed Sheller cleaners are used for calibrating and super-fine cleaning the product with the desired quality and sizes. Oats and gleanings inside the product are taken out with the help of indent cylinders. We offer a range of sunflower seed shellers that comes in a different capacity. The offered machines are designed to clean, de-hull, peel, sort, and check the sunflower seeds without harming them. These machines are high in demand for their sturdiness, high performance, low maintenance, resistance to wear and tear, etc. You can contact us anytime to place your order(s) and we assure you to deliver the orders in the promised time frame. Polishing Machines are used at the end of the seed processing line. It is used for treating the seeds with homorganic liquid. So that seed is protected from insects and harmful microorganisms. After all the cleaning and sorting processes, the product is packed and delivered. Order our machines for your need today.

Cotton Seed Dehulling Machine

Get Price Quote

1 Piece (MOQ)

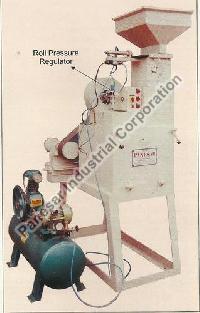

Rubber Roll Paddy Dehusker

Get Price Quote

1 Piece(s) (MOQ)

Our research and development efforts have been continuously focussed on the goal of achieving the optimum performance and durability of Rubber roll Paddy dehuskers. Our dehuskers offer the advantages of decreased breakage with improved rubber roll life. Other Details : The Rubber Rolls automatically engage and disengage triggered by proximity switch in response to the amount of paddy in feed hopper on top of the machine The Rubber Rolls automatically adjust their position to the decrease in diameter of rolls The constant husking pressure is fully assured irrespective of wearing rubber rolls which help to ensure uniform husking The dehusking pressure is adjustable by roll pressure regulator according to paddy conditions and operating requirements

Groundnut Decorticator With 4 Hp Motor

74,000 - 90,000 Per Machine

1 Piece (MOQ)

chironji seed decorticator

120,000 - 155,000 Per Piece

1 Piece (MOQ)

Semi Automatic Rice Huller Machine

Get Price Quote

1 Unit (MOQ)

rice husker

Get Price Quote

Pulses Hulling Machine

Get Price Quote

1 Piece (MOQ)

Features Emery Stones (Silicon cabide) Screens Gap adjuster (for gaps between stones and screens) HIGHEST POWER SAVING Nova has stringent design parameters of dynamical balancing, efficient drives 8 bearing and adjustable counter weight outlet controller. This leads to reduced power requirement for the process. Profitability is greatly improved due to lower powerrequirement combined with high throughput. PERFECT HULLING — INCREASED YIELD The following design features ensure uniform hulling and thereby higher yield. Uniform feeding of the product to the emery stones Geometry of the milling chamber Adjustable gap between stone and screens Adjustable counter weight position at the retaining gate OUTSTANDING DESIGN. HIGHER SERVICE LIFE. LOWER MAINTENANCE. The machined and sectionalized silicon carbide emery stones ensure high service life The stainless steel screens are engineered for low maintenance and long life operation Smooth and quiet (low noise) running The streamlined aspiration system ensures perfect sanitary conditions and efficient removal of separated seed coat

Paddy Dehusker

Get Price Quote

1 Piece (MOQ)

Backed by rich industry experience and market understanding, we are involved in offering a wide array of Mini Paddy Dehusker to our valued patrons.

groundnut decorticator machine

Get Price Quote

1 Piece (MOQ)

Groundnut Decorticator

Get Price Quote

Based in Rajkot, Gujarat, we are engaged in manufacturing, exporting and supplying of Groundnut Decorticator to our customers all over the world. Groundnut Decorticator is manufactured from high-grade material in association with predefined industry norms. The product is used for stripping Groundnuts and appreciated due to its reliable performance. Contact us, for acquiring Groundnut Decorticator at economical rates.

Husk Cleaning Machine

Get Price Quote

1 Piece (MOQ)

Lab Rice Husker

Get Price Quote

1 Box (MOQ)

Based in Ambala, Haryana, India, we are a supplier of high-quality Lab Rice Husker. This premium grain processing machinery is extremely effective in completely dehusking all types of rice easily and efficiently irrespective of the grain size or shape. These machines we offer are sturdily built and very durable and can withstand long-term rough handling and wear and tear easily.

Paddy husker

Get Price Quote

We present Paddy Husker, which is widely appreciated by the clients due to its high quality and long operational life. We are one of most trustworthy Paddy Husker Manufacturers, Exporters, and Suppliers located in India. Our Paddy Husker comes with rubber roll Sheller and aspirator for separating the husk. Our Paddy Husker is ideal for both dry & wet samples of various kinds.

Groundnut Decorticator Plant

750,000 - 950,000 Per One Unit

Laboratory Rice Husker

Get Price Quote

1 Piece (MOQ)

Groundnut Decorticator

Get Price Quote

1 Pieces (MOQ)

This is a simple machine and its working is easy and trouble free. This is suitable for small units and has the capacity of 800 lbs of decorticating seed in an hour This unit employs friction rolling method to break open the shell with minimum break-age of seeds. The construction is simple, it has a steel frame, adjustable hopper and sieve is of strong section bars to allow adjustments for different size of seeds to fall through. The main shaft has moving wheel on side and fly wheel on the other side. The shaft is supported on ball bearings and heavy fly Wheel ensures the smooth and free movements. The fan bearings are ordinary or self oiling . All the parts are made out of selected materials and are properly machined to give smooth service. This machine can also run on power of 11/2 to 2 H. P. POWER DECORTICATOR These are available in two sizes, each unit has strong Steel Body and is of simple constructions. It is easy to handle and has low maintenance cost. The hoppers fitted to the upper part of the frame and seed passes through the opening chamber, where the shell is broken and separated from the kernel. The kernel and the shells fall through the sieve to the slide board, where the fan blower further clean the kernel before they fall out of machine. THE STONE SEPARATOR is provided with power decorticators only.Two pullies are provided one of beater size Note: We reserve the right to make alteration in the machine from time to time as required.

Grain Dehusker

35,000 Per Piece

1 Piece (MOQ)

Paddy Separator

360,000 Per Piece

Metalco Sales is a customer-focused firm that seeks to provide world-class quality products to its clients. Our company is known as a reliable paddy separator exporter in India. We have a strict quality assurance policy in place to ensure that our activities and processes remain at a high level of competency. The procurement team has been given special instructions that raw materials such as cotton yarn and CRC sheets must only be purchased from reputable sources. In addition, our quality inspectors thoroughly inspect the raw materials before they are transported to the production site. The quality inspectors also keep a close eye on the manufacturing process to guarantee that the products we produce meet industry norms and standards. Order from our company today.

Cashew Husk Cleaning Machine

908,000 Per Piece

Laboratory Rice Husker

32,000 Per Piece

1 piece (MOQ)

hulling machines

Get Price Quote

Hulling machines highest level of perfection, the Rice Dehusker is sure to be free from any defect. Rice Dehusker, available with us, requires very low maintenance. Also, the offered Rice Dehusker is user-friendly.

Seed Decorticator

80,000 - 130,000 Per Piece

1 Piece (MOQ)

Laboratory Rice Husker

Get Price Quote

2 Piece (MOQ)

4620 Bajaj CEC Hull Beater

Get Price Quote

1 Piece (MOQ)

Unsurpassed in efficiency, the model 4620 Hull Beater is uniquely designed with a built in tailing beater eliminating the need for additional conveying systems. Capable of handling capacities in excess of 200 tons per day of delinted & undelinted cottonseed, the model 4620 is unequaled in the industry. When combined with the CEC/BAJAJ decorticator /separator system, oil in hulls is maintained at a low level by residual meat recovery to maximum extent, even with 12 % to 14% lint on hulls. ENERGY SAVING FEATURES Built in tailing beater eliminating the need for additional conveying systems Common mechanical conveying system for Hull discharge from both chambers. MECHANICAL ADVANTAGES Capable of handling in excess of 200 tons per day of delinted and un delinted seed. Electric motors are conveniently located for ventilation & easy maintenance

Automatic Coconut Dehusking Machine

125,000 - 250,000 Per piece

1 piece (MOQ)

Coconut dehusking is the process of removing the husk or outer covering of a coconut fruit. Traditionally, this process has been done manually using tools like machetes or spikes, which requires skill and training. However, there is a shortage of skilled workers, leading to lower production rates and safety hazards.

Pneumatic Rubber Sheller

255,000 Per Piece

Double Shaft Coconut Husk Shredder Machine

300,000 - 500,000 Per piece

1 piece (MOQ)

A green as well as brown coconut shells can be shredded in our double shaft shredder which is used to shred large quantities of coconuts fast on a daily basis, for SHREDALL quality and reliability are paramount. We take pride in offering top-of-the-line double shaft coconut shredders that are built to last even in outdoor conditions. Our products are not only high-quality but also come with unbeatable prices and warranties, making them a smart investment for businesses worldwide. With our commitment to excellence, we ensure that all our small, medium as well as large coconut shredders are manufactured to the highest standards, delivering efficient and reliable performance with every use. Whether you need in the farm or are in the food industry or agricultural sector, our agri shredders are designed to meet your specific needs and exceed your expectations. When you choose SHREDALL for your coconut shredding needs, you can trust that you're getting a superior product that is built to last. Experience the difference with our world-class coconut shredders – shipped worldwide for your convenience. The Basics of Double Shaft Coconut Shredder The double shaft coconut shredder represents a significant advancement in shredding technology, specifically designed to address the unique characteristics of coconut husks. Unlike conventional shredders, which may struggle with the tough and fibrous nature of coconut husks, the double shaft design ensures thorough and efficient shredding. Key Features Dual Shaft Configuration Robust Construction Versatility Efficient Drive System Safety Features Easy Maintenance Shredding Material The machine is designed to handle Coconut Usage/Application The double shaft coconut shredder finds applications across various industries and sectors, including: Coconut processing plants: Efficiently processes coconut husks and other waste materials generated during coconut processing. Agricultural industries: Facilitates the conversion of coconut waste into valuable resources such as mulch, compost, or biofuel. Waste management facilities: Contributes to sustainable waste management practices by shredding coconut waste for recycling or disposal. Capacity With a shredder from 100 kgs/hr to 5000 kgs/hr, the machine is available for small, medium to large-scale operations. Automation Grade The Shredder Machine is Automatic, which makes it easy to operate. Motor Power The machine runs on a 3-phase power supply, ensuring efficient and reliable performance. Country of Origin Made in India, the SHREDALL industrial Shredder Machine are designed and manufactured entirely in INDIA. Product Description Coconuts are not only a popular tropical fruit but also a source of various byproducts, including coconut husks. However, managing coconut husk waste efficiently has long been a challenge due to its tough and fibrous nature. Traditional methods of disposal often lead to environmental pollution and resource wastage. In response to this problem, the introduction of the double shaft coconut shredder promises a revolutionary solution, offering efficient and sustainable coconut waste management. Conclusion The introduction of the double shaft coconut shredder marks a significant advancement in coconut waste management technology. With its efficient shredding capabilities, robust construction, and versatility, the shredder offers a sustainable solution for processing coconut husks and other coconut waste materials. By revolutionizing coconut waste management practices, the double shaft coconut shredder contributes to environmental conservation and resource optimization in coconut-producing regions worldwide.