Filler Boards

Get Price Quote

We produce the filler board for the flush door & modular door. They used this filler board as filler into the doors. It’s very easy to use. You can increase your door manufacturing capacity by using the filler board. Filler Board is termite proof so you don’t need to do termite treatment to the door.

Thermoplastic Expansion Joint Filler Boards

Get Price Quote

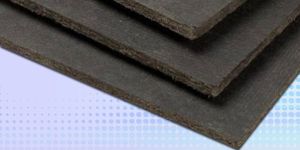

Thermoplastic Expansion Joint Filler Boards are available as per IS 1838 / (Part I). Thermoplastic Expansion Joint Filler Board is processed to satisfy the performance requirements specified by Bureau of Indian Standard IS � 1838 � 1983. Thermoplastic Expansion Joint Filler Board is made from cane fiberboard impregnated with Bitumen. Penetration of Bitumen chemical inside the boards is done with the expertise to provide the water resilience until the last part of the board which makes it suitable for & perform with excellence in various difficult conditions of concrete structures. Also, it provides suspension to the concrete structure to sustain the difficult situations of the atmospheric changes, settlement of foundation, sudden & spontaneous load, etc. Thermoplastic Expansion Joint Filler Board is available in the large thickness 10mm, 12mm, 18mm, 25mm, 40mm, and 50mm. Available Sizes : 1.22 Meter x 1.22 Meter (4' x 4') & 0.610 Meter x 1.22 Meter (2' x 4')

Best Deals from Joint Filler Board

Bitumen Expansion Joint Filler Board

160 - 1,200 Per piece

100 piece (MOQ)

Bitumen expansion joint fillers, also known as bituminous joint fillers or asphaltic joint fillers, are materials used to fill expansion joints in various structures, such as bridges, highways, and buildings. These fillers play a crucial role in accommodating movements caused by temperature variations and preventing the ingress of water and debris. Here are some features associated with bitumen expansion joint fillers:1. *Elasticity:* - Bitumen expansion joint fillers exhibit elasticity, allowing them to deform and accommodate the movement of the joint. This property is crucial for preventing damage to the structure.2. *Water Resistance:* - Bitumen joint fillers are known for their water-resistant properties. They create a barrier that helps prevent water infiltration into the joint, protecting the underlying structure from water damage.3. *Adhesion:* - These fillers adhere well to the joint surfaces, ensuring a secure and durable connection. Proper adhesion helps maintain the integrity of the joint over time.4. *Flexibility:* - Bitumen fillers remain flexible over a range of temperatures, allowing them to adapt to thermal expansion and contraction without cracking or losing effectiveness.5. *Durability:* - Bituminous joint fillers are durable and capable of withstanding environmental factors, including exposure to sunlight, rain, and temperature extremes.6. *Resistance to Aging:* - Bitumen expansion joint fillers are designed to resist aging and degradation over time. This helps ensure a longer service life and reliable performance.7. *Ease of Installation:* - These fillers are generally easy to install, making them suitable for construction projects where efficient installation is essential.8. *Compatibility with Bituminous Surfaces:* - Bitumen expansion joint fillers are compatible with bituminous surfaces, making them well-suited for use in asphalt pavements and other bituminous structures.9. *Minimal Shrinkage:* - Bituminous joint fillers typically exhibit minimal shrinkage after installation, helping to maintain a tight seal in the joint.10. *Cost-Effective:* - Bitumen fillers are often cost-effective compared to some other types of joint fillers, making them a practical choice for various construction projects.11. *Resistance to Chemicals:* - Bitumen expansion joint fillers can resist the effects of certain chemicals, contributing to their overall durability and performance in harsh environments.12. *Availability in Various Forms:* - Bitumen expansion joint fillers are available in various forms, including sheets, rods, or pre-molded shapes, providing flexibility for different applications and project requirements.It's important to note that the specific features of bitumen expansion joint fillers can vary based on the product formulation, manufacturing process, and intended application. When selecting a bitumen expansion joint filler, it's advisable to refer to product specifications provided by the manufacturer to ensure that it meets the project's requirements.

Bitumen Expansion Joint Filler Boards

15 - 26 Per meter

100 Piece (MOQ)

Benefits Of Expansion Joint Filler Boards : Durable Lightweight Non-absorbent No bitumen contents Simple and easy to handle Ability to compress and recover Non-extruding from joint movement Non-staining and very easy to apply Suitable for submerged or trafficable joints Specifically formed foam board for expansion joints Keep the installation unscathed and impart the safety Resistant to specific hazardous chemicals, acids and more Resilient and deliver compression recovery after deflections Absorb-up the stress produced by increased and decreased temperatures Have a good load-bearing capacity and transfer less stress to the structures Areas Of Application : Slab on ground Brickwork and blockwork Reinforced concrete structures Concrete roads and pavement Basement and tunnels Water retaining / excluding structures Dams and reservoirs Bridges and viaducts Suspended slabs Airport aprons and taxiways

Expansion Joint Filler Board

450 - 900 Per BOARD

50 BOARDS (MOQ)

Expansion Joint Filler Board is a soft fiber board impregnated with bituminous material to render it durable and water proof. It is compressible and possesses high degree of recovery after compression load is released, thereby ensuring that no free space exist in between joint space. Expansion Joint Filler Board is manufactured as per IS-1838:1961 standards. Salient Features : Contain bituminous material High degree of recovery after compression Made up of soft fiber Durable Water proof Cost effective Size : 4 x 4 boards of length x breadth: 1.22mtr x 1.22mtr (1.49 sq. meter) Available In (Thickness) : 12mm 18 mm 25 mm Used As Concert Board In : Roads Runways Buildings Bridges Decks Canals

Expansion Joint Filler Board

400 Per Piece

20 Piece (MOQ)

Expansion Joint Filler Boards

Get Price Quote

Bitumen Joint Filler Board

100 - 200 Per sqm

Expansion Joint Filler Board

Get Price Quote

10 Pieces (MOQ)

We are the leading organization actively occupied in providing an extensive series of Expansion Joint Filler Board. This product is presented in numerous of specifications.Dura board HD100 its also called as filler boards, these filler boards are used in civil application for eg - Expansion joints,expansion between walls etc.Additional Information:- Item Code: HD100 Delivery Time: Immediate

Polymer Based Expansion Joint Filler Board

3,000 - 5,000 Per Box

30 Box (MOQ)

Features & Benefits Closed Cell – Negligible Water / Moisture Absorption Bitumen Free – Non-Staining, Non-Impregnated And Non-Bleeding. Does Not Disintegrate Easy To Use – No Crumbs, Dust Or Fibers. Can Be Cut With Knife For Easy Installation Excellent Chemical Resistance – Unaffected By Alkalis, Alcohols, Detergents, Petrochemical Products And Most Mild Acids Excellent Recovery Hence Can Accommodate Joint Movement Does Not Discolour Sealants Or Architectural Substrates Applications Structural Expansion Joint In Buildings Buildings Brick And Block Work Isolation Joints Between Adjacent Constructions, E.G. Buildings, Around Manholes, Drains And Other Insets In Concrete Etc.

Pure Expansion Joint Filler Board

Get Price Quote

Road construction needs lot of consideration, including the harmful effects of climate on the products used in constructing them. Extreme climates may change the characteristics of these product and cause harm to the road structure. These chemicals and products can expand or contract. For example concrete slabs vary during winter and summer. In tropical countries where climates are extreme it can cause more hazardous effect to transportation. In order to correct this expansion and contraction and maintain road surface evenness, expansion joints are provided in between the butting slab. Commonly for runways and highways, both traverse and longitudinal joints for expansion are provided. Their width is generally 12mm, 18 mm or 25mm. These are inserted between regular intervals and at intersection with other constructions. An expansion joint filler board is a soft board made out of cane fiber. These cane fiber boards are water resistant and bitumen imbued. They are available as boards and strips. These are known for their characteristics of resisting compression.

Filler Boards

Get Price Quote

We are backed by vast experience in the production of Filler Boards, Joint Filler Boards and Joint Expansion Filler Boards. Our Filler Boards are designed in compliance with the international standards and this makes us one of the trustworthy Manufacturer and Supplier of Filler Boards from Bangalore, Karnataka, India. Cutting-edge technology and best quality material is used to make our different types of Filler Boards. They are resistant to contraction and compression. Our Filler Board For Expansion Joints do not absorb water and resistant to all weather conditions.

Shalitex Board

Get Price Quote

Shalitex Expansion Joint Board is cane fiber soft board impregnated with Special Grade of Bitumen. It is a perfect base material for expansion joint filers. The board's compression and recovery characteristics conform to the U.K., U.S.A. and Indian Standards much above the required averages. Shalitex Expansion Joint Board displays excellent resistance to compression, with outstanding recovery characteristics. The boards are environment friendly as opposed to the environment destroying thermos Cole/plastic expansion joint boards. Application Filling structural expansion & structural separation joints in block & in situ concrete construction including screed floors, motorways, roads, runways, pedestrian areas, bridges, curbs, basements, retaining walls, site slabs, subways & other structures etc. Filling all types of expansion joints in piers and lateral supports like abutments. Various other flat works and concrete floors. Storage Keep in cool dry place under shed away from heat. Health & Safety Use goggles and hand gloves during application. Clean hands with warm soap water after application. Packing Available in 12, 18 & 25 mm board normally in 4 Ft x 4 Ft. Other thickness may be catered to on request. It is available in a wide range of sizes, both as boards & strips in thicknesses of 12, 18 mm & 25 mm. Application Methodology Permit free movement of the concrete slabs during expansion and contraction. To provide a waterproof seal. To resist entry of foreign matter into the joint space. Application methodology. Remove dust, flakes or foreign particles by jet or dry air and clean the surface. Apply appropriate primer like ShaliTex Primer, ShaliJet Primer, ShaliSeal PS Primer in the groove where SEJ Board is to be applied. Cut SEJ Board of appropriate width from the desired thickness and place the same in the groove in a way to flush with the external surface except for space required for ShaliBar / other sealants. In case of a new casting, SEJ Board of appropriate width is fixed with copper screws before pouring concrete. The width is designed to flush with the external surface except for space required for ShaliBar / other sealants. In highway construction, SEJ Board is placed appropriately 20 mm below surface of finish level of pavement and filled with ShaliTex Sealing Compound / ShaliJet Sealing Compound / ShaliSeal PS.

Expansion Joint Filler Board

Get Price Quote

100 Piece (MOQ)

We take pleasure to introduce ourselves as one of the renowned exporter, manufacturer & supplier of jolly board expansion joint filler in mumbai, maharashtra, india. Jolly bitulex softboard is processed from cane fibre, the raw material tested and proven to provide the best resilience. Impregnated with bitumen in various percentages, it is a perfect base material for expansion joint fillers. The board's compression and recovery characteristics confirm to the u.k., u.s.a. And indian standards much above the required averages.

Expansion Joint Filler Board

Get Price Quote

pre-moulded, compressible joint filler board. It is readily compressible filler board that ensures low load transfer. ‘DURAboardHD100’ (expansion joint filler board) is a non-bituminous superior alternative to bitumen boards,Closed cell hence negligible water water vapour absorption.

Bitumen Impregnated Expansion Joint Filler Boards

Get Price Quote

Expansion Joint Filler Board

Get Price Quote

20 Square Feet (MOQ)

PE joint filler boards

Get Price Quote

We offer Pe Joint Filler Boards. It is a Cross linked Closed cell Polymer. It is widely known as compressible Expansion Joint Filler Board and is flexible as well as has high compression-recovery, therefore suitable for application at places which require readily compressible low load. This filler board is non-tainting and therefore suitable for use in potable water retaining and water excluding structures. It is very light weight and easy to handle and install. It can withstand severe weathering conditions and shows no sign of disintegration or degradation. It is a sheet form in semi-rigid, UV resistive, high performance laminated closed cell polyethylene foam joint filler. It is suitable for use as expansion joint filler in concrete, brick, block work and isolation joints where readily compressible low load transfer joint filler is required. Competitive Advantages of the product 1 Flexible 95% recovery after deflection (compression). 2 Weathering Test Resilient and does not distort under low load transfer from wet concrete 3 Closed cell structure Extremely low water absorption thus non deteriorating and durable 4 Bitumen free Non-Staining 5 Chemically Resistant Inert to most dilute acids, resistant to oil and hydrocarbons 6 Hygienic Rot proof and bacteria resistant 7 Simplicity Easy to handle & install it Available sizes: a. 1mtr x 2mtr b. 1200mm x 1800mm(Generally supplied this size) c. 1500mm x 1600mm

Expansion Joint Filler Board

Get Price Quote

We bring forth Expansion Joint Filler Board which is made of compressed dry wood fibers impregnated with bitumen. The Expansion Joint Filler Board prevents cracking due to change in the weather and also allows joint to freely expand in summer and contract in winters without damaging the concrete slabs. Besides, our Expansion Joint Filler Board also restricts the deposition of foreign material that facilitates free movement of concrete during expansion and contraction and thus prevents cracking. Applications : External wall cladding Traffic surface and internal surface Building structure Reinforcement concrete structure Bridges, highways, roads Highlights Of Expansion Joint Filler Board : Highly durable Environment friendly High tear resistance

Joint Filler Boards

Get Price Quote

With our years of experience and expertise, we are making available premium range of Joint Filler Boards in the market. We have segregated our infrastructural facility into different units and one of them in warehouse wherein we keep a huge lot in safe and secured manner.Features : Excellent strength Flawless finish Durable