flow wrapper machine

400,000 Per Piece

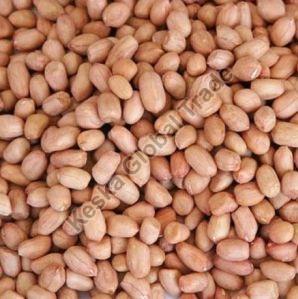

Groundnut Kernels

55 - 78 Per Kilogram

10 Ton (MOQ)

Groundnut kernels is one of the important legume crops of tropical and semiarid tropical countries, where it provides a major source of edible oil and vegetable protein.Groundnut kernel contains 45-53% oil and 24-26% protein.Peanut kernels are usually eaten as is, by cracking them with firm pressure between fingers.Peanut butter is a food-paste made from ground-roasted nuts. Groundnut kernels have a high fibre content, protein and have a positive effect vision.It is useful for people who are suffering from Type 2 Diabetes.Phytosterol is an important substance in peanuts, which helps in struggling with lung cancer.

Best Deals from Pouch Packaging Machines

Liquid Pouch Packing Machine

Get Price Quote

1 Piece(s) (MOQ)

Groundnut

Get Price Quote

(In shell & Kernel):- Groundnut is the major oilseed of India. It accounts for around 25% of the total oilseed production of the country. Annual production of Indian Peanuts and Indian Peanuts oil are around 5-8mln and 1.5 mln tons respectively. Peanuts Production is highly vulnerable to rainfall deviations and display huge fluctuation between years. Global trade of Indian Peanuts or Indian Groundnut oil is to the maximum of 100000 tons a year. EU and US are major importers. Senegal and Argentina are the major Peanuts exporters. Types:- Java: Counts per ounce: 40/50 45/55 50/60 60/70 70/80 80/90 100/120 120/140 140/160 160/180 Bold: Counts per ounce: 35/40 38/42 40/45 40/45 45/55 50/60 60/70 70/80 Specifications:- Moisture: 7% max OR 8% max (as per customer requirements) Admixture: 1% max OR 0% max (as per customer requirements) Foreign Material: 0.50% max OR 0.00% max (as per customer requirements) Oil content: 42% - 48% max Aflatoxin: Aflatoxin negative-5 PPB (TLC method)- 10 PPB (HPLC/ELISA method with B1B2 contion)- 20 PPB (HPLC/ELISA method with B1B2 contion)- as per customer requirement Safflower seeds: for Bird feed and oil seeds.

collar pouch packing machine

Get Price Quote

1 Pack(s) (MOQ)

We are offering collar pouch packing machine. Item code: model-sps402 we have in-store for our clients collar type packing machine which are compact and robust in construction. Being a high speed form fill and seals machine these are used for packing of salt, detergent, tea, coffee, salt, ground spices, rice, milk and powder. Besides, these are fully automatic and offers fast packaging of various products. Also, low maintenance and less power consumption makes them widely appreciable by our clients. Specification: packing material-laminated films roll width max - 400mm, min. 100 mm pouch type-center seal pouch dimension - width = 50 -200 mm, height = 65 300 mm electrical supply - 230 v a.c single phase 50 hz power consumption - 3kw production rate- varies as per the nature of product & filling range net wt.-550 kg weight - approx. 700 kg

Pouch packing machine sps 1000 for oil

390,000 Per 1000 Kilogram

Drive: The Drive is through a single phase motor and a reduction Gear Box, chain Sprocket Drives and Main cam shaft. As well as Cam Box the mechanical cam fitted on this shaft controls the Jaws movements and film fee, the Electrical cam switches bank driven by this shaft controls sealing, cooling, and film feed duration. Forming of the Film Tube: The Heat Sealable film roll is mounted at the rear side of the machine, on the suitable rollers, secured by tapered Supports the film layers, in front of a ultra violet sterilization tube before it is engaged in the forming device. The specially designed former convert this layer into a tube. Vertical Seal: When film tubes comes out of forming device centrally by A vertical electrode fitted on holder fixed on vertical Press or Jaw which is moved forward by a cam on the Drive shaft. This is an impulse Heated Electrode, cooled by circulation of cold water through an opening in the Holder. The formed film tube surrounds the injection or Filling tube through which the product to be filled flows in the film tube. Down Feed: Vertically centre sealed film tube is pulled down by the Nip Roller controlled by clutch break, pair of bevel Gears and chains. Horizontal Seal: By horizontal seal, the sachets are sealed and separated from one another by the sealing electrodes while the Jaws are closed. The OIL from the main tank placed near the machine is pumped to the top inlet of the injection pipe and the film tube surrounding the injection pipe is filled with the liquid. The pump is specially designed and speed of the pump motor is adjustable with the help of another inverter called pump inverter. The speed of the pump motor is adjusted to suite the speed of the Machine and Quantity of Liquid to be packed.

heat shrink packaging machine

Get Price Quote

Heat Gun tools are used for loosening of jammed bearings, nuts, bolts, mechanical spare parts. In addition, our Heat Gun is used for the removal of paint, wall papers, varnish and putty from various metal surfaces. We design these guns at our state of the art machining facility using best quality materials and sophisticated technology.

butter packing machine

Get Price Quote

butter packing machine, Dairy Equipment, dice blender

Pouch Packing Machine

Get Price Quote

Supari packaging machine