industrial robotic system

800,000 Per Piece

1 Piece (MOQ)

Robotic Cell Entire Protection System

Get Price Quote

Provides Complete Robotic protectionwith Machine safety curtains. Safety Relay. Interlock switches, LASER Scanner. Self-Checking Touch Buttons E-Stop Buttons

Best Deals from Robotic System

Abb Computer DSQC639

265,000 Per Box

1 Box (MOQ)

brand : abb model : dsqc639 quantity :01 condition : new upc : does not apply seller note : without seal pack.

Five Axes Servo Driven Robot

Get Price Quote

1 Piece (MOQ)

Duct Inspection Robot

200,000 Per Piece

Robotic Forging Automation System

Get Price Quote

Loading & unloading through robot. Depends on the temperature robot is keeping the hot component on the die or otherwise keeping in rejection chute.

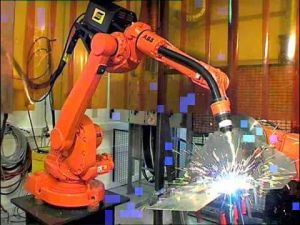

robotic welding system

2,000,000 Per Piece

1 Piece (MOQ)

Robotic Welding Systems (SPM).Our complete product range is manufactured under the supervision of trained personnel who use the utmost quality raw material.

robotic welding system

1,400,000 Per Piece

1 Piece (MOQ)

cartesian robot

Get Price Quote

A cartesian coordinate robot (also called linear robot) is an industrial robot whose three principal axis of control are linear (i.e. they move in a straight line rather than rotate) and are at right angles to each other.The three sliding joints correspond to moving the wrist up-down, in-out,back-forth. Among other advantages, this mechanical arrangement simplifies the Robot control arm solution. Cartesian coordinate robots with the horizontal member supported at both ends are sometimes called Gantry robots. They are often quite large. A popular application for this type of robot is a computer numerical control machine (CNC machine) and 3D printing. pick and place of medicines to conveyor Glue dispensing bot precision pick and place injection moulding used in assy.

Automatic Cartesian Robot

400,000 Per Units

Robotics Integration system

100,000 - 1,000,000 Per Piece

Prima can supply complete Robotics Integration of reputed make with complete PLC and accessories integration. Solutions that we can provide are Pick and Place, Paletizing, Welding, Painting, Stacking, Packing, etc

Automated Touchscreen Testing Robot

Get Price Quote

1 Set(s) (MOQ)

Used for automated real device testing -- rigorous, functionality & manual testing on capacitive and resistive touchscreen devices like smartphones, tablets, laptops, multi-touch tv screens, infotainment systems & touch-sensitive industrial hmi panels. Sr-scara-pro is built to improve the accuracy & efficiency of touch screen testing. It is the world's fastest touchscreen testing robot, upto 800 touches per minute. Can do touch gestures -- single & double tap, long press, swipe & zoom (requires different end effector for zoom). Vision feedback of the testing routine can be obtained through camera (does not come with base unit) it can be interfaced to matlab, labview, ros and other software applications. For further info: www.sastrarobotics.comsolutions checkout our products and solutions: www.sastrarobotics.com email: hello@sastrarobotics.com immediate enquiries: +91 4846 422 422 applications capacitive touchscreen testing resistive touchpanel testing touch enabled hmi panels testing industrial touch control panels testing smartphone gestures testing vision feedback of touch testing automated real device testing touchpanel testing r&d for educational institutions and industries specifications design: 3 dof touch speed: 800-per-minute payload (mid-range): 0.5 kg horizontal reach : 350 mm vertical reach: 30 mm work area: 332000 sq mm weight: 3 kg controller: intel-based pc control box interface: usb, optional lan , can available mounting: floor mounting, wall mounting, roof mounting power input: 230 v, 50 hz ac software robot simulation & control software provided, with built in kinematics solvers, trajectory generation & collision avoidance. Programmable to customer requirements open source apis in cc++, python, labview, matlab. Ros interface simulation models for gazebo, webots, v-rep

Laser Robotic Welding System

Get Price Quote

We are offering Laser Robotic Welding System. technical details: laser type : fiber laser laser wavelength : 1064 nm average power : 1 to 6 kw positional repeatability : 0.06 mm no. of axis : 6 nos. dimension height : 1584 mm manipulator bases : 732 x 600 mm power consumption : 200-600v/ 50hz supply transformer : 4 kva/ 7.8 kva materials : stainless steel, mild steel, aluminium * technical specs are subject to change without prior notice. features: • micro weld • consistently high weld quality • consistent pulse overlap on seam welds • fill the area - several parallel offset welds • semi-automatic weld with intuitive joystick path teaching • high pulse to pulse stability for fine micro weld • easy, intuitive parameter setting even for beginners • stable laser beam quality for better marking quality • suitable for automatic production benefits: • precise welding - small laser point • 3d welding possible • 1mm to 10mm sheet welding • depth / width ratio is high • heat affected on material is less • higher speed with low distortion • no air bubbles • reduced impurities • higher strength of welding line • can weld two varieties of metals together applications: arc welding, assembly, cleaning, cutting/ deburring, glueing/sealing, grinding/polishing, machine tending, material handling, packing.

Traversing Servo Robot

250,000 - 350,000 Per Piece

1 Piece(s) (MOQ)

We follow strict quality strategy, guidelines and thus, to sustain good quality standards, we carry out stern examination of the raw inputs used at the initial stages. With our inventory management system, we are capable to undertake urgent and massive requirements of the buyers at a time.

Robo Pouring System

5,000,000 - 8,000,000 Per Piece

1 Pound (MOQ)

industrial robots

Get Price Quote

robotic system

Get Price Quote

We are deal with all type of robotics system integration like welding application, machine tending cell, Handling & Palletizing Cells, Integration & Programming Services,

Robotic Palletizing & Depalletizing Solutions

100,000 - 150,000 Per Piece

Robotic solutions offer ultimate quality control and end-to-end flexibility in palletizing and depalletizing requirements. Offered by Bricspac, robots with customized tooling and configurations are available for the discerning customer who values time and efficiency in a high-volume high traffic application that also demands nimble functionality and short turnaround times.

investment casting Robotic Shell System

9,000,000 - 30,000,000 Per Piece

1 piece (MOQ)

The Robotic Shelling System - The automated and robotised shell production solution for an Investment-Casting foundry. Shelling is done by dipping the wax assemblies in a series of ceramic slurries and coating them in refractory sands. It is critical that this process is fully automated using a robotic shelling system; any inconsistencies in the shell thickness and porosity, that arises from uneven sanding or draining of the ceramic slurries, or improper drying process can cause trouble later in the process. Resulting in defects in the castings and hence rejections. Doing all these processes manually simply does not give the precision or repeatability to perform this task in a satisfactory manner. RoSS is a comprehensive shell room solution, which aims to completely replace human effort to more a efficient and reliable robotic system. To produce complete shell from first coat to seal coat – ready for de-waxing. • Shell building is performed as per dip sequence selected. • Maintaining drying time between coats as per instructions. • Intelligent prioritising of conveyor sequence to ensure minimum robot idle time. • System controlled slurry and sand levels. • System includes: 7 machines, 6 conveyors, 6 fans, robot and track. • As low as 2 persons are required to operate the entire Shell Room. • When compared to manual dipping, output per shell may be increased by upto 30% by increasing shell size, • Upto 15% saving in shell materials due to reduction in wastage and optimised shelling.

SCARA Robots

Get Price Quote

Industrial robots play an important role in the development of automated production. To meet the high requirements for industrial robots, Delta's ASDAMS series robot controller is equipped with real-time performance, high flexibility and highly competitive motion controlcapabilities.The ASDA-MS series perfectly integrates robot controller, multiple servo drives, Delta's self-developed high-speed DMCNET communication network and general communication interfaces into one unit that provides high speed, and high precision and high performance. Delta's Programmable Automation Controller (PAC)MHI Series features the perfect integration of motioncontrol and logic programming control. It enablesbetter synchronization with EtherCAT and DMCNETcommunication and can connect to various slave modules and servo systems with either an EtherCAT or DMCNET network interface. These communication interfaces offer high response and high precision control for more flexible operation, and are ideal for high-performance multi-axis motion control. Robot Controller with Servo Drive Integrated ASDA –MS : Complete Robot Solution Integrated servo drive and controller in one single unit for real time motion control with high fl exibility and reliability. Supports various communication protocols Built-in with diverse robot control modules Up to 10 axes motion control: 4-axis robot + 6 external axes Supports IEC 61131-3 standard for fi ve kinds of programming languages and the PLCopen motion function block Offers DRL Languages for developing robot application programs Supports G-Code programming for path planning

Robot Machine

500,000 Per Piece

SCARA & Articulated Robots

Get Price Quote

otc robotic welding systems

Get Price Quote

We are the most reliable Manufacturer, Exporter and Supplier of high-tech OTC Robotic Welding Systems, which are widely used for the purpose of welding. Our wide range of OTC Robotic Welding Systems includes Robotic Arc Welding System, Robotic Spot Welding System and Robotic Mig Welding System. Our OTC Robotic Welding Systems are manufactured according to the laid industry standards and also tested according to them. The OTC Robotic Welding Systems provided by us promise to deliver a high quality consistent performance with much precision.

All type of Eoat Robot gripper spares

8,000 - 22,000 Per Piece

10 Piece (MOQ)

We have manufacturer & supply of all type of Robotics Gripper Parts,we also manufacture as per customer requirements,light weight,durable,flexible,safer.spring mounted double blank detector quick change for cross bar Feeder,Hexa Feeder,Loader unloader

industrial robot

200,000 Per Set

Automotive Robot

490,000 Per Piece

1 Piece(s) (MOQ)

�Mirror / Glass Assemblies �Screwdriving for transmission components �Ignition module assembly �Head and tail light assembly and test �Transmission sub-assembly �Clutch assembly �Dashboard component sub-assembly �Brake line assembly �Crankshaft and camshaft sensor assembly �Hood and trunk latch / lock assembly �Fuel injector assembly �Bearing assembly

cartesian robot

350,000 Per Piece

robotic welding system

Get Price Quote

industrial robots

Get Price Quote

We are offering industrial robots. Rugged design of the robot. Reinforced profiles for higher load rating and longer durability. Integrated connection technology for vacuum and gripper circuits. Modularity of the robot mechanics and of the drive and control system architecture.

Robotics Process & Integration Simulation

Get Price Quote

Robotics process & integration, simulation brings brilliant takeaways for manufacturing organizations. This digital manufacturing solution delivers you a virtual 3D environment to work and enable speedy works being completed within seconds. These integrated solutions are the need of the hour for every manufacturing organization and we, Shiv Technology work on giving you the top automated solutions for your smooth workings. Why are robotics, process & integration, simulation, a valuable tool? Considering a tool the most worthy for your business unit without knowing about its privileges is not as easy as it looks. But for you, we are bringing here the reasons of should you adopt it and how could it prove as valuable to your firm. Great production quality, faster launches, proper optimization, validation, and simplifying manufacturing processes make it the most valuable tool. It vouches for extreme safety while moving, carrying material or performing operations, enhanced efficiency and of course higher productivity. The operations abide by quality control techniques. The best part is, everything is carried on by adhering to the safety standards. So robotics process and integration simulation by Shiv Technology is completely safe to use and keep the hazardous outcomes at bay. Specifications Greater flexibility Exquisite quality Assured results Safe to use Applications Upfront virtual validation is possible leading to less physical prototypes Early detection of product related issues Reuse of standard facilities and tools, and hence, the cost reduced Ergonomically safe processes can be carried on Simulation of various manufacturing scenarios is possible and as its takeaway, the production risk gets reduced. Production commissioning validation is attainable Emulation of realistic processes which ultimately enhance process quality. With robotics process and integration simulation, you get a lot of benefits with the smooth manufacturing process. The flaws get automatically abated, which results in minimum wastages and increased outputs. We guarantee the quality and performance of this tool. We hope, now you get to know how is it helpful and more precisely, valuable to your unit? So, when are you resorting your manufacturing unit to robotics process and simulation integration? Contact us, share your requirements and resort to this flawless tool.