Batching Controller

50,000 - 150,000 Per Piece

1 Piece (MOQ)

Mettler Toledo Batch Controller

225,000 Per Unit

1 Piece (MOQ)

Engineered for the food, specialty chemical, plastics, glass and aggregates batching and formulation markets, IND780batch works as a stand-alone terminal for single- or multi-scale applications. It offers configurable IO with high speed cut-off and Ethernet connectivity for PCs. Installation and setup are quick and easy, providing a “box-to-batch” solutionThe IND780 batch provides multiple control options. The system is easily adapted to most batching, filling and formulation applications, providing functionality forautomatic, semi-automatic and manual modes of operation. It also supports automatic material transfer with input fromup to four scales.Stand-Alone OperationOperating without the need for a PLC or DCS system,the IND780batch is equipped with a large, easy-to-read color graphics HMI display.Easy ConfigurationIND780batch includes libraries for materials, formulas and containers.Recall stored data for use in production with a barcode scan to improve process efficiency and avoid errors.Increased ManufacturingEfficiencyEnhance your automatic material transfer batch process by adding the Q.iMPACT® predictive filling control feature

Best Deals from Batch Controllers

Auto batch controller for construction equipment

25,000 - 200,000 Per piece

1 Piece (MOQ)

In the realm of construction and infrastructure development, concrete remains an indispensable building material. Whether for constructing towering skyscrapers, resilient bridges, or sturdy residential structures, the quality and consistency of concrete are paramount. To ensure this consistency, the utilization of an Auto Batch Controller for batching plants has become essential. This intelligent system not only automates the batching process but also enhances precision, efficiency, and overall productivity in concrete production. Auto Batch Controller: A Fundamental Component A batching plant is a vital part of any concrete production facility, responsible for combining various raw materials, such as cement, aggregates, water, and admixtures, in precise proportions to create concrete batches. The Auto Batch Controller serves as the brain of the batching plant, overseeing and regulating the entire operation. It's a comprehensive automation solution that transforms the traditionally labor-intensive and error-prone process of concrete batching into a streamlined and highly accurate operation. Key Features and Functionalities Precision Batching: The Auto Batch Controller excels in delivering precise batch compositions. It achieves this by accurately measuring and dispensing each ingredient in line with the predefined mix design. This precision is crucial for ensuring the structural integrity and durability of the resulting concrete. Recipe Management: The system allows for the storage and retrieval of multiple mix designs or recipes, making it easy to switch between different concrete types as per project requirements. This feature not only saves time but also minimizes the risk of errors. Automation: The controller automates the entire batching process, reducing the reliance on manual labor. From ingredient proportioning to mixing and discharge, the system ensures a seamless and efficient workflow. Real-time Monitoring: Real-time monitoring is a key advantage of an Auto Batch Controller. It provides operators with live data on each batch's progress, ingredient levels, and any deviations from the desired mix. This information is vital for immediate intervention in case of issues. Data Logging and Reporting: The system maintains a comprehensive log of every batch, offering historical data for analysis and quality control. Detailed reports on batch quality and production metrics are readily available, assisting in process optimization. Integration: Auto Batch Controllers are often compatible with plant control systems and can seamlessly integrate with other equipment, such as conveyors, silos, and mixers. This integration optimizes plant efficiency and ensures smooth material flow. User-friendly Interface: Modern Auto Batch Controllers feature user-friendly interfaces, often with touchscreen displays. This simplifies operation and reduces the learning curve for plant personnel. Benefits of Using an Auto Batch Controller Enhanced Accuracy: The system's precision in proportioning raw materials significantly reduces variations in concrete quality, leading to consistently high-quality end products. Increased Efficiency: Automation not only speeds up the batching process but also minimizes human errors. This results in higher production rates and lower operational costs. Cost Savings: Reduced waste, accurate material usage, and decreased labor requirements all contribute to cost savings, making an Auto Batch Controller a financially sound investment. Quality Assurance: By closely monitoring each batch, the system ensures that the concrete produced adheres to specified standards, contributing to safer and more durable structures. Environmental Benefits: The ability to optimize raw material usage and reduce waste is not only cost-effective but also environmentally friendly. Remote Operation: Some modern Auto Batch Controllers offer remote monitoring and operation, allowing plant managers to oversee the process from off-site locations

SmartLoad Batch Controller

Get Price Quote

Smart Load® Electronic Preset used to measure & deliver precise quantities of Product in loading and retail applications. Features: Controls Single or blended product loading with additives & Blends Direct interface with flowmeters, Safetyinterlocks, card readers & automationsoftware Controls Digital Controlvalves, additiveinjector blocks Can Control up to 4 products / blends and six additives Temperature & Pressure compensations asper API, IP or linear methods W&M approved for use in custody transferas per OIML R117. PESO, IECEx , ATEX approved for use in Gr. IIA, IIB.

Batch Controller

Get Price Quote

The ASHE MX-450 is a micro-controller based Digital Flow Rate Indicator Totalizer offered in a highly compact, rugged and reliable execution. There are two digital displays on the front panel – the Rate Display and the Totalized display. The RATE display indicates the real time process value and the TOTALIZER display indicates the accumulated (integrated) volume over the selected time scale. The totalized value is displayed on an eight digit counter with non-volatile memory. The flow rate is continuously displayed on a four-digit seven-segment digital display.

batch controllers

Get Price Quote

Our Batch Controller is an intelligent microprocessor-based Batch Controller for Fluid Metering Installations. It can operate either in a "MANUAL" or "AUTO" mode. It has been designed to perform various batch loading applications, such as Tank Trucks, Rail Cars, Industrial Barrel Filling, Barge for Petroleum Liquids, Aviation Fuel, LPG, LNG, Lube Oils, Chemicals, etc. Our Batch Controller communicates with Loading Rack Computer, Gauging Computer and if required, with other Peripheral / Host devices. Batch Controller has an ex-proof and weatherproof housingSalient Features: Large (240 x 128) Graphic Liquid Crystal Display or Large 6-digit back-lit LCD display Latest Generation Microcomputer Design Dual Communication Ports Pulse Security Conforming to IP - 252 / ISO 6551 Menu Driven Operator Interface Multi functional Alpha-Numeric Keyboard Optional Host Communication Redundancy Data Storage up to 200 transactions(Expandable) Field Programmable Options Self-diagnostic Meter error curve linearization Tamper-proof and sealed calibration facility and approved by Weights & Measures department Accepts all types of interlocks for fail-safe operation Can be used with any make of flow meters and pulse generators RS 232 / RS 485 connectivity Flameproof enclosure for hazardous area application Weatherproof to IP – 65 Electronic Batch Controller: Our Batch Controller has Microprocessor based integrated batch loading system and dual communication port system. The offered Batch Controller is a powerful flow computer, designed to meet the requirements of all types of fluid Metering installations for refuellers, tank trucks and marine applications.

Batch Mix Controller

35,000 - 75,000 Per Pieces

Rmc Batching Controller

Get Price Quote

1 Piece(s) (MOQ)

We offer RMC Batching Controller is used in construction equipment machinery, it is having features to handle any types of batching in concrete batching plant, it can control 6 Aggregate , 2 Cement, water and chemical also, it is most famous controller in construction equipment , it is having 100 recipe , and it can store up to life time, it is having 1000 cycle dada logging facility , other like infly, set point, date, time, material open delay, close delay, dead weight etc it having lot off facilities Use 1) Inline Batching Plant 2) Mobil batching Plant 3) Any types of Batching plant

Rmc Batching Controller

50,000 Per Piece

1 Piece (MOQ)

GM8806A-PL Robust Weighing & Batching Controller

Get Price Quote

The GM8806A-PL is a highly effective weighing and batching controller. It is successfully utilised in chemical, agro, building materials and many other industry domains. This batch weighing controller features a strong design and provides optimum functionalities.The batch weighing controller provides versatility and precision in its weighing and batching functions. It is made of ABS front panel and cast aluminium body. It enables storing of up to 40 recipes for diverse batching capacities. It comes with a multiple hopper application. It is CE approved, possesses long operational life and offers intelligent calibration without weights.The weighing controller offers to switch between weighing, bagging and batching operations. It further reduces additional inventory requirements for our intended distributors. It provides a superior blend of performance and flexibility.It is one of the best weighing controllers that enable electronic calibration, multiple FIR digital filters with 9 selectable levels and auto-zero at power weighing functions. It backs with 19 Self-defined functions with digital input functions for packaging mode. It even provides 17 Self-defined functions for batching digital outputs and 20 Self-defined functions for packaging mode based digital outputs.It further supports Standard MODBUS RTU, Standard MODBUS ASCII and follows general measure protocols. It backs 3 feeding speed and comes as jog-feeding supported.Key Features Selectable up to 4 types of material batching 14 I/O ports (4 inputs and 10 outputs) Easy Switch between the 3 function modes(weighing, bagging, batching), reducing inventory need for our distributors Power-loss Protection function allows continued operation right after power-loss Compact and ergonomic design for large systems where panel space is constrained Allows the option of having both analogue and serial communication port simultaneously Storing up to 40 recipes for different batching capacity Advanced free fall compensation algorithm for extremely precise result every time. Product Highlights Robust construction Long operational life Smart calibration without weights CE approved

batch controllers

Get Price Quote

Be it online or cash deposit, the financial operations are carried out only under the stern management, supervision of professionals. To make our payment procedures highly secured, we make use of the leading technologies to avoid any fraud. Due to our streamlined packaging system, we are capable of meeting both standard and customized packing needs of the clients. Moreover, we make use of quality packaging material.

Batch Controller

3,001 Per Piece

Batch Controller

Get Price Quote

We are a major Manufacturer and Supplier of Batch Controller. Batch Controller and indicators for conveyor belt weighing are majorly meant for use in mining industry. We offer accurately designed and precisely manufactured Batch Controller that comes with multiple digital inputs and outputs. The Batch Controller offered by comprises of indicators with analog signal output for control through PLC. The output of the Batch Controller includes 4-20 mA current or 0-10 V voltage. The peak hold indicator of the Batch Controller is useful for logging the peak load on scale. Further, we also supply the Batch Controller with optional alphanumeric LCD, Graphic LCD, VFD and LED displays.

GM8804C-A6 Batching controller

Get Price Quote

Key Feature CE approved 20 I/O control ports (8 inputs / 12 outputs) Perfect balance between speed and precision with automatic three-speed feeding Controls up to 6 kinds material batching process Smart calibration without weights Storing up to 40 recipes for different batching capacity Patent pending two-layer advanced digital filtering algorithm Advanced free fall compensation algorithm for extremely precise result every time Two serial communication ports to connect with computer, printer and/or a second display

Batch Controller

Get Price Quote

Accepts Universal inputs – 4-20 mA or 0-10 V or pulse (2 or 3 wire) Non-volatile memory to retain Totalistic flow Liner or Square root input selections with 0.1% Accuracy 810 digit Flow Totalistic with password protected resetting Retransmission and RS-485232 communication Available Weather proof or flame proof housing GSM mobile connectivity for wireless remote reading purpose. (sms)

Digital Batch Controller for Batching

Get Price Quote

This instrument is useful for controlling input feeding mechanisms to feed/fill required quantity of material into a tank/hopper/bag. A maximum of 6 material can be batched using this controller, each with coarse/fine feeding. Four opto-isolated digital inputs are provided for controlling the batching process. A high resolution and high speed ADC is used for digitizing the load cell signal and 5000 external counts are provided. RS485 serial communication is provided for interfacing to PC. The instrument operates using 230 V AC SMPS based power supply. All control outputs provided are open collector type and external relays are required for operating feeders. Firmware is provided for calibrating the instrument, for entering the setpoints and other batching parameters, for displaying the cumulative batching data and for communicating with a PC. All batching parameters can also be downloaded directly from the PC and every batch can be monitored and stored in the PC. The PC software is also available as an option.

Batch Controller Unit

85,000 Per Piece

Batch House Controller

Get Price Quote

The batch house controller provided by us are used to process, fine-tune and control capability of common packages. Manufactured using advanced programming interface, our batch house controller comprises features like: analog display panel backlit lcd displays four-button keypad to adjust the batching system

Weighing, Batching And Dosing Controllers

Get Price Quote

Weight indicator in DIN case, dimensions 96x96x130 mm. IP54 front panel protection (IP65 optional). Four-key membrane keyboard. Eight indicator LED. Possible installations : panel, wall (W200BOX-EC) Six-digit red LED display (14 mm height). RS232 and RS485 pots (Modbus RTU/Laumas ASCII protocol). 3 logic inputs, 5 relay outputs. Optional : Data storage on USB pen drive 16-bit analog output: 0/4-20 mA; 0-5/10 V; ±5/10 V Alibi memory Additional RS485 port Fieldbuses : Profibus DP, DeviceNet, CANopen, Profinet IO, Modbus/TCP,Ethernet/IP, Ethernet TCP/IP for remote management (connectable to yourPC, smartphone, tablet, etc. via web) Certifications : OIML R76:2006, class III, 10000 divisions 0.2 μV/VSI OIML R61 – WELMEC Guide 8.8:2011 (M.I.D.) On request : GOST-R – Russia UL Recognized component – United States and Canada W200 series weight indicator into IP67/IP64 box Polycarbonate box, dimensions 170x140x95 mm, four fixing holes Ø4 mm, 6 PG9 cable glands. Five-key membrane keyboard. Eight indicator LED. Wall mounting. W200BOXEC External switch for formula selection (EC option), Sart and Stop buttons. W200 series weight indicator into explosion proof box The system is composed of: Explosion proof box, ATEX II 2(1) GD approved, provided with heat-resistant transparent tempered glass window and 5 external buttons which performs the same functions as W200 keyboard. W200 series weight indicator. Passive fail-safe Zener barriers, ATEX II (1) GD approved.

Sand Metal Batch Controler

Get Price Quote

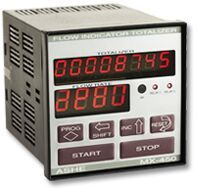

Batch Controllers-855

Get Price Quote

BATCH CONTROLLERS FLOW INDICATORS – Predefined Universal type MODEL 855 ( Microprocessor based & Fully Configurable ) Introduction Pantech Instrument’s Model 855V represents BATCH CONTROLLERS FLOW INDICATORS AND TOTALIZRS for flow applications where single flow signal is available. Model 855 is an ideal instrument for controlling amount of material flow in every batch. The input signal can be a currentvoltagelinear signal from a flow transmitter or pulses from turbine meters. It can also be UNIVERSAL input type, where user is allowed to select and configure the input signal. The analogue signal is square rooted if required, and similarly for digital pulses LitrePulses ratio ( i.e. K factor )can be adjusted to achieve precise measurement of flow and hence batching. The desired counts or the BATCH VALUE(S) are set through push button switches given in front of instrument. The relay(s) isare energised to start the flow and batch counter starts. When set batch counts are reached, relay(s) get de energised as per the batch-relay settings and the flow is stopped. The cycle repeats when start button is pressed again. The flow can be interrupted during the working cycle by pressing stop button and again started by pressing start.

Rmc Batching Controller

Get Price Quote

Batch Weight Controller

Get Price Quote

Batch Weight Controllers are used for Digital Weighing of Batches of Dry Bulk Materials under Gain-In-Weight principle. In a typical arrangement the Batch Weigher is mounted on Load Cells connected with Junction Box and the Batch Weight Controller. Based on the set points the Feeding Equipment ( like Screw Feeder or Vibratory Feeder ) will refill in Bulk and Dribble mode under repeatable Gravimetric Accuracy.

Batching Controller

Get Price Quote

Weighing indicator C8+ adopts fast speed ∑-Δ A/D conversion technology. It is widely applied in electronic batching scale、electronic fix-value scale and electronic catchweigher, sort of control system. Meanwhile, it has function for Max and Min limitation alarm and peak value preserving.

Hopper Batching Controller

Get Price Quote

We are offering hopper batching controller. Hopper batching controller is panel mounted weight controller, this controller is used to control weighing quantity on hopper up to four materials, it is having four relay output for controlling material filling in hopper. specifications brand: planet automation systems hopper batching controller is having set point facility in which we can set required weight and infly, also it is having printing facility in which we can printing actual material field in hopper, this controller is wildly used in industrial as well as construction equipment, it is having good stability on industrial envoirmental, and this indicator is made for sites and industrial use, use: 1) mobile concrete batching plant 2) process industries 3) beaching of material

Batch Controller

Get Price Quote

Product Details: Accepts Universal inputs – 4-20 mA or 0-10 V or pulse (2 or 3 wire) Non-volatile memory to retain Totalistic flow Liner or Square root input selections with 0.1% Accuracy 8/10 digit Flow Totalistic with password protected resetting Retransmission and RS-485/232 communication Available Weather proof or flame proof housing GSM mobile connectivity for wireless remote reading purpose. (sms)

Ultra Mass Series Batch Control Systems

Get Price Quote

Ultra mag series standard’s sanitary batch control system engineered for bulk, precision dosing and filling operations from drums, tote® tanks and kettles – virtually hands-free. This system utilizes a non-invasive full bore magmeter for flow volume measurement. Simply dial in desired volume, press enter, and the sanitary batch control delivers a preset volume of material within .05% accuracy. The system is an excellent solution for conductive food products, pharmaceuticals, and cosmetic materials. Common applications lotions shampoo chocolate pie fillings juice concentrates brine pharmaceuticals tomato paste features 3a certification large graphic display tri-clamp® fittings low shear design non-invasive measurement easy to clean design multi-language display standard or metric units of measure measures volume

Batch Controller

Get Price Quote

Accepts Universal inputs 4-20 mA or 0-10 V or pulse(2 or 3 wire). Maximum 4 CO on Batch values generated. Liner or Square root input selections with 0.1% Accuracy.

Cement concrete batching plant controller

Get Price Quote

Salient Features: Sturdy Controller for the plants ranging from 20 cu.m to 60 cu.m The controller can accommodates four types of aggregates, two types of cement, fly ash, two types of chemical additives, fresh water and recycled water. Simple and easy to use. Generates all data information for Project.

Batch Controller

Get Price Quote

The microprocessor-based Batch Controller is meant for fluid meter installations and it can work in manual or auto modes. Capable of handling batch loading of various kinds, the Batch Controller communicates with loading rack computer and gauging computer. We are a highly distinguished Manufacturer, Exporter, and Supplier of Batch Controller, which can work with other peripheral/host devices and has a weatherproof housing.Applications Tank Trucks Rail Cars Industrial Barrel Filling Barge for Petroleum Liquids Aviation Fuel LPG LNG Lube Oils Chemicals Salient Features Pulse security conforming to IP - 252 / ISO 6551 Multifunctional alphanumeric keyboard Field programmable options RS 232 / RS 485 connectivity Weatherproof to IP – 65 Self-diagnostic Data storage up to 200 transactions (Expandable) Can be used with any make of flow meters and pulse generators Tamperproof and sealed calibration facility and approved by Weights & Measures department Accepts all types of interlocks for fail-safe operation Dual communication ports Menu driven operator interface Optional host communication redundancy Latest generation microcomputer design Meter error curve linearization Flameproof enclosure for hazardous area application Large (240 × 128) graphic liquid crystal display or large 6-digit backlit LCD display.