tin coated copper wire

900 - 1,500 Per Kilogram

100 Kg (MOQ)

Tin Coated Copper wire is made by going through 3 process. Ist process is this that the wire is drawn in a specific size with Electrolyte (C.C. Rod ) Copper and after doing the drawing process of the same then it goes to IInd process in which Annealing is done and after that the IIIrd process comes in which Tin Platting is being treated in this drawn Electrolyte Annealed Copper Wire which is done in 2 ways normally:-Hot Dip ProcessIn this process the Tin is being melted in Electric Pot and the Electrolytic Copper Wire is made dip through this melted Tin which results in Tin Coated Copper wire.Electroplating ProcessIn this process the wire is gone through a Chemical Tray and with the help of rectifier and Electric Current to DC Current is passed which results in electroplating, this process is used for House Wiring, Control Panel Cable & Other Electric & Electronical Wire as well as Cable too.Tin Coated Copper wire is complex shape wire and cable. Tin coated copper wire in use as overhead power source for subways, light and heavy transit systems, electrically powered mine trains, buses, and industrial cranes. Tin coated copper wire likely also touches conduit, and other similar things etc.Tin Coated Copper wire is complex shape wire and cable. Tin coated copper wire in use as overhead power source for subways, light and heavy transit systems, electrically powered mine trains, buses, and industrial cranes. Tin coated copper wire likely also touches conduit, and other similar things etc.Tin is a chemical element with symbol Sn (for Latin: stannum) and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group-14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4. Tin is the 49th most abundant element and has, with 10 stable isotopes, the largest number of stable isotopes in the periodic table. Tin is obtained chiefly from the mineral cassiterite, where it occurs as tin dioxide, SnO2.This silvery, malleable post-transition metal is not easily oxidized in air and is used to coat other metals to prevent corrosion. The first alloy, used in large scale since 3000 BC, was bronze, an alloy of tin and copper. After 600 BC pure metallic tin was produced. Pewter, which is an alloy of 85–90% tin with the remainder commonly consisting of copper, antimony and lead, was used for flatware from the Bronze Age until the 20th century. In modern times tin is used in many alloys, most notably tin/lead soft solders, typically containing 60% or more of tin.Tin Coated Copper WireThe popularity and use of copper wire in the electrical and Manufacturing industry is well known to all. Due to copper´s high electric conductivity and thermal conductivity, wires created from copper are widely used in various industries.Once the wires of various dimensions are drawn from copper, it may be further processed using tin, which creates tin coated copper wires. There are two ways to create tin copper wire –hot dipping and electroplating. In the first method called hot-dipping, strands of copper are dipped into hot tin, which produces the required tin copper wire. In the second method, rectifier and electrical charge are used to tin the copper wires.Advantages of Tin Copper WireThere are several inherent advantages of tin copper wire as compared to non-tinned copper wire such as longevity and anti-corrosion properties. It has been observed that tin copper wire lasts longer and produces amazing results even after years of deployment. On the other hand, non-tinned copper wires are not able to last as much longer.Additionally, tinned copper wire reflects anti-corrosion properties which make them effective in marine usage as well as in those areas which have high moisture and humidity. Lastly, tin copper wire has more electrical conductivity as compared to non-tinned copper wire.Such wires are extremely useful for industries such as electrical power industry, electrically powered trains, trams, trolleys, marine industry etc. Tin coated copper wires are also extensively used in industrial cranes and automobiles such as cars, buses and trucks.If you are searching for best quality tin coated copper wire, then your search ends right here. Ganapati Engineering provides high grade and stable tin coated copper wires, which are preferred and recommended by some of the top manufacturers and producers. For more information related to our company, you can check out our home page here.

Tin Coated Copper Wire (ATC)

1,000 - 1,200 Per Kilogram

100 Kilogram (MOQ)

Best Deals from Copper Coated Wires

tin coated copper wire

Get Price Quote

In order to do tin coating on copper wire the material needs to go through a serious of process. First, the Electrolytic Copper Wire is drawn into the specific size required through various machinery. Secondly, the material is annealed and then tin coated is done on it by two process:- Electrolytic Process This is a process in which the material passes through chemical tank and with the help of electric current on the tin slab the tin coating on the copper wire is done which comes evenly onto the material as required. Hot Dip Process In this process the tin slab is melted into an electric pot and the material is being made passed through it which results in tin coating on it. Use The Tin Coated Copper Wire is used in various types of cables, industrial machines, heaters, high temperature instruments and various other types of instruments.

Copper Coated Wires

Get Price Quote

Copper Coated Wires, Electrical Wires

Copper Coated Wires

Get Price Quote

Copper Coated Wires, Annealed Copper Wire, Submersible Pump Winding Wire

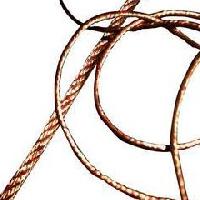

Braided Tin Coated Copper Flexible Wire

Get Price Quote

We are offering best Braided Tin Coated Copper Flexible Wire

copper coated clad wire

Get Price Quote

copper coated clad wire