Single Skin Roofing Sheet

100 Piece (MOQ)

Roof & Wall Cladding Panels Metal Panels are one of the most attractive features of metal building systems. ‘’panel’’ refers to the metal skin used as roof and wall panels, interior roof and wall liners, partition panels, Fascia Panels, Soffit Panels etc. Deoki Steel Panels The base metal is high tensile steel with high grade aluminum zinc alloy coating, comprising 55% aluminum, 45% Zinc weighing 150 gram/m2 spread over both sides. This compared offers our times higher resistance to corrosion as compared to galvanized coating. Deoki Color Coated Steel Panels have 5 micron primer paint and 20 micron silicon modified polyester paint applied at the mill on the weather (Exterior) face. Deoki also offers PVF2 (Fluro Polymer) using minimum 70% Kynar/Hylar-500 Resin, which ensures that your building continues to look beautiful or a life time.

...more

CZ purlins

SECONDARY MEMBERS/ COLD FORMED MEMBERS Secondary structural framing refers to purlins, girts, eave struts, wind bracing, flange bracing, base angles, clips and other miscellaneous structural parts. Purlins, girts and eave struts are cold formed steel members which have a minimum yield strength of 345 MPa (50,000 psi) and will conform to the physical specifications of ASTM 572 (Grade 50) or ASTM A653 (Grade 50) or equivalent. A horizontal secondary structural member, bolted to the rafters, which transfers the roof loads from the roof covering to the primary frames.

Shape : "Z" & "C"

Material : Galvanized

...more

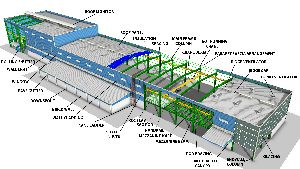

PreEngineered Building

Pre-engineered steel buildings (PEB) are a steel structures built over a structural concept of primary members, secondary members, roof and wall sheeting connected to each other and various other building components. These buildings can be provided with different structural and non-structural additions such as skylights, wall lights, turbo vents, ridge ventilators, louvers, roof monitors, doors & windows, trusses, mezzanine floors, fascias, canopies, crane systems, insulation etc., based on the customer’s requirements. All the steel buildings are custom designed to be lighter in weight and high in strength. Thus steel building designs have become more flexible, durable and adaptable over the last four decades which has made steel one of the preferred materials for building construction. PEB’s are ideal for non-residential and wide-span low-rise buildings. Some of the key advantages of PEB include economical in cost, factory controlled quality, durability, longevity, flexibility in expansion, environmentally friendly, faster installation, etc. Pre-engineered steel buildings are used for diverse applications such as factories, warehouses, showrooms, supermarkets, aircraft hangars, metro stations, offices, shopping malls, schools, hospitals, community buildings and many more. As a leading PEB manufacturer, Deoki Technocrafts provides the complete service of engineering, fabrication and erection thus ensuring better quality control at every stage of the process. Pre-engineered steel buildings consist of following components : Primary Members / Main Frames Secondary Members / Cold Formed Members Roof & Wall Panels Accessories, Buyouts, Crane System, Mezzanine System, Insulation, etc. Sandwich Panels Pre Engineered Buildings Our pre-engineered building system is unmatched in its speed and value. Buildings, to suit specific needs, are designed, engineered, manufactured and shipped in less than 8 weeks and at a cost that is as low as 30 percent of the cost of conventional steel buildings (when compared to speed of occupancy and space usability). Clear spans up to 93 meters wide and eave heights as high as 30 meters are possible. From planning to occupancy, nothing matches Deoki Technocraft's Pre-Engineered Building System in terms of versatility, flexibility and total value-engineering. The pre-engineered building system is, without doubt, one of the fastest growing building systems in the world. The advantages that it offers appeal to all parties involved in the project. After all, who can resist a building system that offers speed, quality and value. Applications of pre-engineered buildings are numerous. Described in few words, pre-engineered buildings are ideal for any non-residential low-rise building. Our pre-engineered steel building consists of the following : Primary framing (The main frames) Secondary framing (Z and C sections) Roof and wall panels, single skin and insulated sandwich panels) Structural subsystems (canopies, fascias, partitions, etc.) Floor systems (mezzanines, catwalks, platforms, etc.) and Other building accessories (sliding doors, roll up doors, windows, louvers, etc.) Primary Framing Primary members are the main load carrying and support members of a pre-engineered building. The main frame members include columns, rafters and other supporting members. The shape and size of these members vary based on the application and requirements. The frame is erected by bolting the end plates of connecting sections together. All the steel sections and welded plate members are designed in accordance with the applicable sections as per the latest international codes and standards such as AISC, AISI, MBMA and IS to meet all the customer specifications. Deoki Technocraft's pre-engineered buildings are custom-designed to meet your exact requirements. The most common Primary Framing systems are shown below. Practically any frame geometry is possible. Consult a Deoki Technocraft's representative for your specific requirements. Primary Build-Up Members: Minimum yield strength is 34.5 kN/ cm2 At Deoki Technocrafts we can produce other non-standard main frames, of almost any configuration, if required. High grade steel plate conforming to ASTM A 572M Grade 345. Factory painted with a minimum of 35 microns (DFT) of corrosion protection primer. Secondary Framing SECONDARY MEMBERS/ COLD FORMED MEMBERS: Secondary structural framing refers to purlins, girts, eave struts, wind bracing, flange bracing, base angles, clips and other miscellaneous structural parts. Purlins, girts and eave struts are cold formed steel members which have a minimum yield strength of 345 MPa (50,000 psi) and will conform to the physical specifications of ASTM 572 (Grade 50) or ASTM A653 (Grade 50) or equivalent. Purlins, girts and eave struts are secondary structural members used to support the wall and roof panels. Purlins are used on the roof; girts are used on the walls and eave struts are used at the intersection of the sidewall and the roof. Secondary members have two other functions: Act as struts that help in resisting part of the longitudinal loads that are applied on the building such as wind and earthquake loads Provide lateral bracing to the compression flanges of the main frame members thereby increasing frame capacity. Purlins, girts and eave struts are available in high grade steel conforming to ASTM A 607 Grade 50 or equivalent, available in 1.5 mm, 1.75 mm. 2.0 mm, 2.25 mm, 2.5 mm and 3.0 mm thickness. They come with a pre galvanized finish, or factory painted with a minimum of 35 microns (DFT) of corrosion protection primer. Minimum yield strength is 34.5 kN/ cm2 Crane & Mezzanine Deoki Technocrafts Steel building is ideal for factory buildings and manufacturing facilities which require installation of cranes for material handling. Our buildings can be designed to support various systems upto 300 MT. Deoki Technocrafts Standard Mezzanine Floor Systems consist of Galvanized Steel Decking Supported by joists connected to main mezzanine beams. A reinforced concrete slab (not supplied by DTPL) is cost in situ on top of steel decking The primary mezzanines beams usually run across the width of the building and the joist usually run lengthwise.

...more

Polycarbonate Sheet Insulation Services

Consider our name if you are seeking professional assistance that can handle your sheet insulation requirements. At DT, we are a group of industry experts, who provide solutions that are functional and comply with the elevated industry norms. Besides, our polycarbonate sheet insulation services are rendered using modern-day insulating material and as per clients’ requirements. We are operating from Jaipur (Rajasthan, India) and can be approached anytime for further discussion. Our service charges are also reasonable.

...more

Heavy Structural Fabrication

DTPL provides complete-steel work solutions for pre-fabricated heavy steel structures including connection design, detailed drawings, manufacturing and fabrication, surface treatment and protection, delivery, and erection. DTPL with CNC & ROBOTIC automated manufacturing systems has the capability to do various Infrastructure projects such as airports, aircraft hangers, power plants, cement plants, steel plants high-rise buildings, bridges, Multi-Level parking, stadium, and other industrial applications. DTPL’s Production units feature specialized robotic plasma cutting, drilling, and submerged-arcwelding machines, with its in-house team of qualified engineers, technicians, welders, riggers, fitters, and detailers. The advantages of shop Fabrication over site fabrication are excellent welding quality, dimensional accuracy, faster delivery in volumes, and long-lasting paint finish. Advantages of DTPL Plate Welded Beams Enhanced cycle and durability Time-saving as manufactured on automatic online cutting and welding lines Steel saving in excess of 20% as lower sectional weight beams can achieve higher load-bearing capacity. Ideal for bolted or fabricated construction. Offer tremendous flexibility in designs beams are entirely custom made. Shot blasted and paint aesthetically superior. FABRICATED BUILD-UP SECTION I-BEAMS, T-BEAMS, H-BEAMS The fabrication area of built-up sections equipped with 2 No. Saw welding machines. 1 No. CNC profile cutting machine. 1 No. 1/H beam assembly machine. 1 No. Flange straightening machine. FABRICATION STEEL PRODUCTION LIVE Sections fabricated from high tensile plate. Sections design for optimized weight. Automatic material handling. Automatic twin head welding. Service holes cut in beam webs as required.

...moreBe first to Rate

Rate ThisOpening Hours