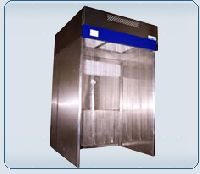

dispensing booths

Get Price Quote

1 Piece (MOQ)

SIS – 1384 These are overhead clean air modules mounted with Stainless steel frame on the ground. Units can be built with/ without casters so the clean enclosure can be moved over equipment or used to isolate a controlled process. It is basically used for filling, refilling weighing and sampling / Dispensing of Raw Material, Basic Compounds, Active Compounds. It works on the principal of Laminar Air Flow with HEPA Filters & Pre-Filters. This will act as a CLASS 100 Room. Protection of the personal in the cabinet from the processed substances by vertical flow with Reverse Flow of clean air protection of the raw and intermediate products to be processed. Protection of the room where the cabinet is built up and environment from highly active substance which otherwise would disperese in the room and escape in the atmosphere unfiltered. Safe collection and deposition of substance released during work. FEATURES •Wooden/M.S. Powder Coated / STAINLESS STEEL BODY (304) •HEPA Filter (0.3 micron) •Fine Filter (5 micron) •Pre-Filter (10 micron) •Motor Blower Assembly •U.V. Light •Fluorescent Lamp •Operatating Switch •Static Pressure Manometer •Stainless Steel Standing Base •High Quality HEPA filter provides protection for the product (filtration efficiency of more than 99.97% at 0.3 micron. •Ultra-quiet noise level of not more than 65 dBA. •Durable and easy to clean stainless steel body. •Work area properly illuminated by diffused glare free fluorescent light. •PVC Flexible Curtains on all the three sides. SPECIFICATIONS: Air Velocity90 ± 20 cfm (Average) Filteration ElementsMain Filters : HEPA Filter PrefilterWashable non-woven polyester fibers. Filter EfficiencyMain Filters : 99.97 at 0.3 micron PrefilterArrestance 91% at 10 microns Fine Filter10 micron Noise Level

Sample Dispensing Booth

Get Price Quote

1 Piece (MOQ)

Best Deals from Dispensing Booth

Sampling Dispensing Booth

274,000 Per Piece

1 Piece (MOQ)

Dispensing Booth

75,000 Per Piece

1 Piece(s) (MOQ)

Our specialization lies in designing Dispensing/Sampling Booth. The Dispensing Booth that we deal in is used to protect the operator from emissions of hazardous dust powders during powder dispensing / sampling. The Dispensing Booths are designed to provide a scavenging arrangement to draw powder, aerosol away from the operator and the operation area i.e. protecting products and operating personnel. The Dispensing Booths are constructed using M.S / S.S � 304, 316 sheets, equipped with filters, blower unit for air circulation. The other features provided with Dispensing are, Magnehelic Gauge, Fluorescent Tubes, etc. The Dispensing Booths can be availed in different specifications from us. We are a prominent Dispensing Booth Manufacturer and Supplier in West Bengal, India. Stream of air circulated vertically downward for achieving the environment. This is a circulating method and the air is always re-circulated through 3 sets of Filters i.e. (10 Micron Pre-filter, 3 Micron Intermediate & 0.3 Micron HEPA Filter) by the blower unit.The downward air stream deflects air borne dust away from operator�s breathing zone and also maintains a cleanliness of class 100. Dust particle is filtered in three levels of filters i.e. primary, intermediate and final (HEPA) which are continuously circulated back to the booths stream during operation. Partial exhaust makes the area negatively pressurised

Powder Dispensing Booth

171,000 - 360,000 Per Unit

1 Unit (MOQ)

Sampling Dispensing Booth

Get Price Quote

1 Piece (MOQ)

Powder Dispensing Booths

120,000 - 800,000 Per Piece

40000 Piece (MOQ)

Powder Dispensing booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing etc., without risk to the operator or environment.

Sampling Dispensing Booth

Get Price Quote

Sample Dispensing Booth

148,000 Per Piece

1 Piece (MOQ)

Sampling Booth has been designed to provide a Class 100 working environment at rest, with built-in scavenging system to ensure protection for the product, operator and surrounding environment. The system comprises: Imported Minipleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3μ at supply position Imported Minipleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3μ at exhaust position Fabtech make prefilter which conforms to EU 4 Grade, with efficiency of 90% down to 10µ. These Filters are basically made from micro-fibre-glass media and are inherently washable Fabtech make Intermediate filter which conforms to EU 7 Grade, with efficiency of 95% down to 3µ. These Filters are basically made from micro-fibre-glass media and are inherently washable Motor Blower provided are statically and dynamically balanced, Supply of sufficient capacity and static pressure is used to take care of airflow requirement for entire life of HEPA. The blower is high-performance, noise abated, light weighted statically and dynamically balanced SS 304 Double Walled Side Panels Mechanical Differential Pressure Gauge (0mm-25mm: 2 Nos.) to monitor pressure drop across intermediate filter Photohelic Differential Pressure Gauge HEPA filter and (0mm-10mm: 1 No.) To monitor pressure drop across PRE Filter with respect to ambient Electrical control panel mounted on the side panel of the unit Tube Light ON/OFF Switches for motor 5/15 Amp single-phase switch socket for external equipment DOP Test port at upstream of HEPA filter

Dispensing Booth

100,000 - 750,000 Per unit

Sampling and Dispensing Booth

Get Price Quote

The company is one of the trusted Manufacturers and Suppliers of Sampling & Dispensing Booth in Secunderabad (India). It is actively involved in the manufacturing of a customized range of Sampling & Dispensing Booth suitable for biotech and pharmaceutical sectors. Sampling & Dispensing Booth that it offers is used for controlling the cross contamination. Details Of Sampling & Dispensing Booth Type of reverse laminar flow equipment : Vertical Material of construction : Stainless steel and CRCA powder coated Electronic feather touch screen controller Mini pleated HEPA filter, daylight Differential pressure gauges Validation & Documentation - as per current GMP standard Especially for powder handling application to control the scattering into other areas Specially designed Reverse Laminar Air Flow for animal handling application - VIVARIUM

Dispensing and Sampling Booth

25,000 Per Piece

Dispensing and Sampling Booth : Alpha Chem is manufactures,exporter & suppliers Dispensing and Sampling Booth. Dispensing and Sampling Booth : These are available in custom sizes and can be availed at reasonable prices. We manufacture and also export a wide range of these booths which are contrived using high grade quality materials. These are well known for its features like durability and high performance. Clients can avail these from us at affordable prices in the market. Technical Specification: Type Re-circulated type or exhaust type. Pressure Drop Pressure Static manometer/ magnehellic gauge provided. Controller Motor on/off indications Light Light and additional. 15/5 amp. Socket provided in the booth. S.S. Double Skin wall and filter aluminum frame structure s.s. And wall acrylic Mini pleat HEPA Filter in supply and fine filter in return air.

Flameproof RLAF Controller

15,000 Per

Dispensing Booth

Get Price Quote

Dispensing booth is a kind of partial purifying equipment for filling, refilling, weighing and sampling of raw material and compounds. It is provided with hepa filter, which prevents the airborne dusts by down draught technique. The unit eliminates powder contamination to protect the operator and the surrounding environment. Dispensing booth is also called sampling booth or weighing booth. Features: 1. Customized design is welcome. 2. Unique designed air duct effectively controls the noise. 3. Smooth transitions of wall and ground can eliminate the blind angle. 4. Differential pressure gauge is equipped to real-time monitor the filters. 5. Intelligent control mode and alarm system ensure the reliability of running. 6. Automatic changeable frequency system monitors the air velocity to ensure its stability in the work area. 7. Uniform flow design of main working area can protects the operators and prevent environmental pollution and cross contamination of products. 8. Dispensing booth(sampling or weighing booth) has primary filters, medium efficiency filters and hepa filters to keep air cleanliness of work area.

Stainless Steel Dispensing Booth

Get Price Quote

dispensing sampling booth

Get Price Quote

Our vast industrial experience has enabled us to manufacture and supply a quality range of Dispensing Sampling Booth. These booths are used in medical and forensic laboratories for providing a protecting environment for the workers. To manufacture these booths we use optimum quality materials, sourced from the most reliable and trusted vendors of the market. We can make the Dispensing Sampling Booth available for the clients in different customized specifications as per requirements. Features: Long working life Fire and dust proof Compact design

Powder Dispensing Booths

Get Price Quote

Powder Dispensing Booth

120,000 - 350,000 Per Piece

1 Piece(s) (MOQ)

Equipment is used for dispensing of powder & chemicals to minimize the risk of contaminating of the work area & ensures the health for working person under the laminar air flow. The equipment is based on 3 level of filtration of air circulation. This ensures that the cloud or particles formed by the material dispensed is sucked from the pre filter, intimated filter & supply with mini pleat HEPA filter. Magnehelic gauge will indicate the pressure difference between the filters. During the initial cycle, we achieve class 100 air with velocity 0.45m/s +/- 20% below working area.Features Class 100 air Air curtain effect, Antistatic PVC curtains is provided Internal coving is provided DOP part up stream is provided Mini pleat HEPA filter eff. 99.997% down to 0.3 micron as a supply filter Pre filter eff. 95% Intermediate filter efficiency 90% Electric Motor with high capacity blower FRP blower with aluminum impeller dia 7"x41/2" Electrical supply 3 phase, 415 volt, 50Hz Velocity 0.45m/s +/-20% below working area Antistatic PVC curtains [optional] 10% of the air will throw out with Hepa filters. Feather Touch buttons for on off the Aux. socket & machine

Dispensing Booth

Get Price Quote

We are recognized in the global market as one of prominent Dispensing Booth Manufacturers, based in India. Our Dispensing Booth restricts the harmful emission of dust, vapor, or powder during various industrial applications like drum tipping, powder dispensing, product sampling, etc. Features Designed in accordance with WHO-GMP 3 Stage Filtration Heavy Duty Low Noise Motor Blower Assembly Suitable to accommodate to floor & table balances Sizes 3'x2' 4"X2' 6Ix2" 4"X3' 4'X4' 6'x3' 6'X4' As Well As Custom-Made Sizes. Optional Accessories Magnehelic pressure differential gauge Flameproof electrical fittings Work table for balance Mini pleat HEPAfilter Ultra violet Tube Comprises of Filtrox make Imported Minipleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3 μ at supply position Filtrox make Minipleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3 μ at exhaust position Filtrox make prefilter which conforms to EU 4 Grade, with efficiency of 90% down to 10 micron These Filters arebasically made from micro-Fibreglass media and are washable Filtrox make Intermediate filter which conforms to EU 7 Grade, with efficiency of 95% down to 3 micron. These Filters are basically made from micro-Fibre-glass media and are washable Motor Blower provided are statically and dynamically balanced, Supply of sufficient capacity and static pressure is used to take care of airflow requirement for entire life of HEPA. Blower is high performance, noise abated, light weighted statically and dynamically balanced SS 304 Double Walled Side Panels. 7 Magnehelic Differential Pressure Gauge (0 - 25 mm: 2 Nos.) to monitor pressure drop across intermediate filter & HEPA filter and (0-10mm: 1No.) To monitor pressure drop across PRE Filter with respect to ambient Electrical control panel mounted on the side panel of the unit. Fluorescent Light (250 Lux) ON/OFF Switches for motor & lights 5/15 Amp single-phase switch socket for external equipment