double cone valves

Get Price Quote

Hyquip Cone Valves are Preffered for handling highly abrasive materials like sintered dust, slag etc and for applications demanding very high differential pressures. These valves are robustly built consisting of double cone and cone seal rings which are actuated through a cam and lever arrangagement. These valves function at a determined speed thus maintaining a uniform flow rate and at the same time the profile of the cone and cone seal rings are so designed to offer a perfect air seal. The internal part of these valves like cone, cone seal rings, are made from special alloy steel for very high abration resistance to ensure longer life. These cone valves are extensively used in sintered plant below ESP's in steel plants. The size of cone valves are choosen from the standard range based on throughput of the material handled, size bulk density, moisture and temperature.

40mm 1.5inch dual plate wafer Type check SS flap 304

690 - 949 Per 1.6

Best Deals from Double Flap Valve

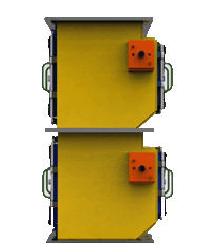

Double Cone Valve

Get Price Quote

DEMECH has supplied Flap valves having inlet size from 200 to 500 mm square. Whereas Cone valves upto of 400 mm diameter have been supplied.The valves need power to open but are closed naturally by counter-weights. The valves are fabricated from mild steel plates with access cover to inspect and attend to the Cone or Flap. Due to low and controlled speed, wear due to abrasive material is minimal. The entry and exit of chamber can be provided with liners for longer life. Cone and seat are casted in suitable wear resistant material to take care of abrasion. The flaps are fabricated either with replaceable liners of hard material or they are manufactured from hard plates like Sailhard or Hardox.The valves are either driven by electric motors or pneumatic hydraulic cylinders. To achieve the alternate and sequential operation, the motor driven valves have specially custom designed cam arrangement and the cylinder operated valves have a sequential timer based controller.

double flap valve

Get Price Quote

Double Flap Valve allows material to flow, while preventing the back flow of air or gas that is critical in many conveying systems. These devices are commonly used wherever dry solids need to be moved between areas of differing air pressure, including ash handling. Typical Double Flap Valve equipment applications include drop-out box hoppers, Dust Collectors, Bag Houses, Precipitators and screw conveyors. Double Flap Valves can handle material like Fly Ash, Sawdust, Lime, Cement, Clinker, Sinter and sand. Other types of material can be collected as long as they are granular, not sticky and flow freely by gravity. This Flap Valve can be motorized, pneumatic & gravity operated.

double flap valve

50,000 Per

1 Piece (MOQ)

double flap valve

Get Price Quote

1 Piece(s) (MOQ)

Being one of the best organizations, we are offering Double Flap Valve. This service is executed by our talented professionals using grade assured material and advanced technology. Our professionals measure all the quality parameters and then render this without any hassle. We render this service in accordance with the demands of our clients. Further, the offered service is highly appreciated by our clients for its hassle free execution and promptness features.

Motorised Double Flap Valve

Get Price Quote

The raw material that is used for manufacturing superior grade products is sourced from the reliable places after complete quality confirmation. We are one of the respected names engaged in the process of supplying quality Motorised Double Flap Valve at nominal rates.

double flap valve

Get Price Quote

HI-TECH valve consists of two flaps connected by counterweights or spring loaded spindles, which are operated by means of a motor driven cam. The cam alternately opens each flap allowing materials to pass through the separate chambers in batch form and thereby ensuring a gas seal.

Double Cone Valve

Get Price Quote

double flap valve

Get Price Quote

Viswakirti valve consists of two flaps connected by counterweights or spring loaded spindles, which are operated by means of a motor driven cam. The cam alternately opens each flap allowing materials to pass through the separate chambers in batch form and thereby ensuring a gas seal.

double flap valve

60,000 Per unit

double cone valves

Get Price Quote

India's Leading Manufacturer With Over 350 Units Supplied. Sizes : 250 Mm, 315 Mm, 400 Mm Supplied To Ferrous & Non Ferrous Plants Also Custom Engineered As Per Specific Requirement

Double Flap Valves

Get Price Quote

UNICON provides a complete line of dump valves (also known as double dump valve, or double flap valves) suitable for air lock applications. Similar to the rotary airlock valve, the dump valve is used in pneumatic conveying systems, dust control equipment, and as volumetric feed-controls to maintain an even flow of material through processing systems. In a dump valve, however, the flow control is accomplished through two chambers.

double flap valve

Get Price Quote

Double Flap valves, also known as or double flap gates, are a type of airlock valve commonly used in industrial applications as a component in bulk material handling applications. Double flap valves are primarily used to discharge chunky or fibrous, bulk materials from hoppers, bins, and cyclones operating under positive or negative pressure. Advantage - Digidale Double flap valves are IDEAL to discharge a flow of material while at the same time serving as an airlock transition point to preserve the pressure differential below the valve. Pressure & Dust-tight construction. This type of material handling valve is ideal for use with bulky or abrasive materials that would tend to jam or damage a rotary feeder. Operation - Double flap valves have two trap-door flap plates which open and close on an alternating cycle. The top gate opens to allow collected material to drop through onto the bottom gate. The top gate then re-closes to prevent air leakage above the valve. The bottom gate then opens to allow material to pass completely through the valve. The bottom gate then re-closes to prevent air leakage below the valve. This cycle is continuously repeated in order to maintain a steady discharge of material from the valve, while maintaining a positive seal on the system.

DOUBLE FLAP VALVE / DOUBLE DUMP VALVE

Get Price Quote

Double Flap Valves, also known as Double Flap Valves or Double Flap Gates, are a type of airlock valve commonly used in industrial applications as a component in bulk material handling applications. Double Dump Valves are primarily used to discharge chunky, pellets, granules or fibrous, bulk materials from hoppers, bins, and cyclones operating under positive or negative pressure. Double dump valves are used to discharge a flow of material while at the same time serving as an airlock transition point to preserve the pressure differential above and below the valve. This type of material handling valve is ideal for use with bulky or abrasive materials that would tend to jam or damage aRotary Feeder Double dump valves have two trap-door flap plates which open and close on an alternating cycle. The top gate opens to allow collected material to drop through onto the bottom gate. The top gate then re-closes to prevent air leakage above the valve. The bottom gate then opens to allow material to pass completely through the valve. The bottom gate then re-closes to prevent air leakage below the valve. This cycle is continuously repeated in order to maintain a steady discharge of material from the valve, while maintaining a positive seal on the system. Each flap plate has its own pneumatically operated cylinder and solenoid valve. The timing of the valve is controlled by an electronic signal sent to the solenoid valves. This method of operation is design to provide first class automation with sequential controller for accurate timing of the desire functioning of the valve.

double cone valves

Get Price Quote

As dust collects inthe hopper, the weight of the dust pushes down the counterweight of the top flap and dustdischarges downward. The top flap then closes, the bottom flap opens, and the materialfalls out. This type of valve is available in gravity-operated and motorized versions.

double flap valve

Get Price Quote

Double Flap Valves, also known as Double Flap Valves or Double Flap Gates, are a type of airlock valve commonly used in industrial applications as a component in bulk material handling applications. Double Dump Valves are primarily used to discharge chunky, pellets, granules or fibrous, bulk materials from hoppers, bins, and cyclones operating under positive or negative pressure. Double dump valves are used to discharge a flow of material while at the same time serving as an airlock transition point to preserve the pressure differential above and below the valve. This type of material handling valve is ideal for use with bulky or abrasive materials that would tend to jam or damage a Rotary Feeder Double dump valves have two trap-door flap plates which open and close on an alternating cycle. The top gate opens to allow collected material to drop through onto the bottom gate. The top gate then re-closes to prevent air leakage above the valve. The bottom gate then opens to allow material to pass completely through the valve. The bottom gate then re-closes to prevent air leakage below the valve. This cycle is continuously repeated in order to maintain a steady discharge of material from the valve, while maintaining a positive seal on the system. Each flap plate has its own pneumatically operated cylinder and solenoid valve. The timing of the valve is controlled by an electronic signal sent to the solenoid valves. This method of operation is design to provide first class automation with sequential controller for accurate timing of the desire functioning of the valve.

double flap valve

Get Price Quote

We are offering double flap valve.

double cone valves

400,000 Per Piece

1 Piece (MOQ)

double flap valve

Get Price Quote

APPLICATION:- double flap valve Ideal for air lock, batching or metering applications in free flowing bulk material.