Lint Slide for Humidification Systems

Get Price Quote

1 piece (MOQ)

The lint slide grid is used to humidify lint as it passes down the lint slide to the baling press. It is composed of stainless steel crosspieces (slats) which overlap to form louver-like openings. Humid air, introduced through the floor of the lint slide beneath the grid, issues from these openings and passes upward through the batt of lint, adding moisture to it. The overlapping arrangement of the slats helps to push the lint down the slide as the lint floats on this bed of humid air and prevents the accumulation of pin trash beneath the grid. Most economical method of restoring moisture Uniform application throughout width Protects fiber quality Recycling of humid air for effective fuel consumption Made with superior technical know-how High quality construction for longer life FEATURES Stainless steel louver grids. Louvers adaptable to existing lint slides. Humid air recirculation increases process economy. Economical and effective moisture restoration. Maintenance free Moisture restoration cost is lowest per bale. No damage to fibre quality. Valve at exhaust chamber to control moisture % restoration.

industrial humidification system

7,500 Per Piece

Best Deals from Humidification Systems

Humidification System

Get Price Quote

Humidification System

Get Price Quote

We state our payment terms on the invoice we sent to our clients. Moreover, our payment procedures remain simple and free from any sort of hassles. We offer both online and offline payment processing. Located in New Delhi(India), our company is involved in making available wide array of products that are in conformance with the industry standards.

humidification plants

Get Price Quote

Humidification plants, DE-HUMIDIFIER EQUIPEED WITH HERMETICALLY SEALED RECIPROCATING OR SCROLL COMPRESSOR.DE-HUMIDIFIER AVAILABLE WITH REFRIGERANTS R22, R134 A, R407C, R404A OR R410A. CONSTRUCTION BODY: M S. POWDER COATED OR FULYY STAINLESS STEEL 304 SHEET & ANGLE. HIGH QUALITY FAN MOTOR WITH LOW NOISE. EQUIPEED WITH ALL ELECTRICAL SAFETY DEVICES LIKE COMPRESSOR OVER HEAT PROTECTION, OVER CURRENT PROTECTION, OVER TEMP PROTECTION , ANTIFREEZE PROTECTION.

Textile Humidification Plant

Get Price Quote

The company is known as the major manufacturer, exporter, and supplier of the advanced textile humidification plant in india. Manufactured as per the industrial standards, our textile humidification plant is known for its excellent performance. The textile humidification plant can be availed at competitive prices from us. used for production of textile yarns known for efficient performancelong working lifesturdyadvanced technology

textile humidification system

Get Price Quote

We are the most promising name, involved in supplying textile humidification system. Ours is a well-established firm located in Coimbatore(India) and engaged in the business of providing a wide assortment of quality products.

Humidification System

Get Price Quote

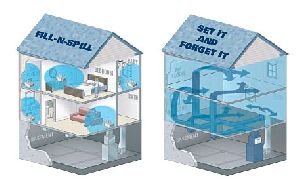

We are offering humidification system. The eshan make humidification systems are designed to clean the air and reduce the temperature of the air and leaving out as cooled air by evaporating method. These humidification systems are widely used in the pharmaceutical,auditorium,textile and food industries. The humidification efficeicy will be more than 95%. Our humidification are backed by good service.

Box Type Eliminator Frame

Get Price Quote

All our payment terms and conditions are as per the requisites of law. A payment agreement signed with the patrons is fulfilled by us ethically and with a high level of transparency. We keep the finished assortment of products in highly developed and spacious space. This helps us in keeping products secure and sorted.

Humidification Plant

Get Price Quote

1 Piece (MOQ)

We have established ourselves as coveted organization, involved in manufacturing, supplying and exporting a wide gamut of Cooling Tower Spare Parts. These parts are developed and designed using high grade raw material mainly stainless steel in compliance with industry laid norms and guidelines. Owing to excellent features such as high tensile strength, high durability and low maintenance, our entire range is widely demanded by our valuable clients. Further, clients can avail these parts from us in a wide range such as Drift Eliminator, Drive Shaft, FRP Fan, Cooling Tower Gear Box, Aluminum Alloy Rotating Sprinkler, FRP Casing Panels, PVC Fills and Stainless Steel Wire Mesh.

Textile Humidification Plant

Get Price Quote

Both of our online and offline payment processing methods are secure for transaction offering you a reliable assistance. We thus accept all kinds of cash payments as well as bank transfers. If you are interested in obtaining Humidification Plant at market leading prices, we are its responsible and responsive suppliers.

textile humidification system

100,000 - 300,000 Per piece

3 Units (MOQ)

textile humidification systems

35,800 Per Units

1 Units (MOQ)

Humidification System

Get Price Quote

Cotton Lint Humidification System

Get Price Quote

Cotton lint humidification and moisture restoration system is a patented product of steamtech engineers and it restores cotton moisture automatically which is reduced during the ginning process. After formation of cotton lint bales, moisture retention system retains moisture content in bales which are stored in godowns. Operating Principle The operating principle of Cotton lint humidification system is, Vapor is generated and cotton is humidified up to desired extent automatically in controlled environment irrespective of external weather. Benefits Strength of cotton fiber is improved. Even humidification can be achieved in whole cotton bale. Colour of cotton fiber is improved. Humidification can be done in accordance to international standards. It prevents formation of fungus in the cotton bales when stored for longer duration. Special Features PLC provides controlled humidification of specified percentage round the clock unless changed. It has sturdy and robust body Another Benefits Modular Construction : The sectional construction reduces the time in project planning, manufacturing, transportation, and finally installation. Energy efficiency: Vapour flow can be managed individually as per the requirement to make sure optimum humidification. Process adaptation: Each parameter such as Vapour flow, Temperature, Retention time of product can be individually managed exactly to suit your humidification requirement. Make in India: The machine is 100% indigenous and patented. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

Humidification System

Get Price Quote

One of the most sought after Manufacturers and Suppliers of Humidification System, we are a renowned name in this domain. To meet industry specific and application specific requirements, we offer Evaporative Humidification and Steam Humidification. With the team of professionals, complete automated system is designed, supplied and installed. We have state of the art manufacturing unit that is equipped with latest machines and technology.

industrial humidification system

19,000 Per Piece

1 Piece(s) (MOQ)

humidification plants

Get Price Quote

The first PID controller receives the RH feedback from the sensor. The RH set point can be programmed through digital display keypad of the VFD. The output of the PID shall regulate the speed of the water pump to maintain the actual RH value according the set point. The RH of the Textile Plant being maintained by the VFD. There is a logic in the system during which the PID action takes place if RH reaches the set level, then the pump will be switched off automatically

Ss Humidification System,

36,000 Per Piece

Humidification System

Get Price Quote