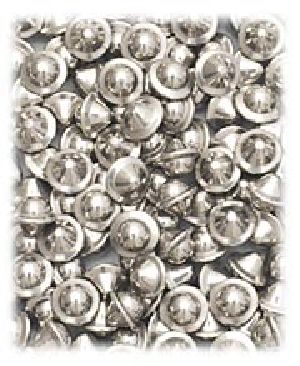

Stainless steel balls

Application : as bearings, bicycle parts, casters and wheels, etc.

Material : Stainless Steel

Non-Ferrous Brass Balls

Brass balls are placed under the category of non-ferrous balls. They provide excellent resistance to corrosion by water, and are substantially lower in cost than other corrosion-resisting balls. Brass balls are frequently used in many types of valve applications requiring small-size balls. Besides, they also have the ability to resist the corrosive effects of fuel oil, gasoline, butane, dry carbon dioxide, benzene, lime-sulphur mixture and similar chemical agents.Brass balls are mostly used for non-bearing applications. Their properties of ductility, good corrosion resistance in moisture and electricity conductivity find them allied applications in machines and components. Brass balls are also used widely in the security and appliance industries for dip and tilt switches. These are available in a range of sizes, tolerances and grades of brass. Other alloys of brass balls available upon request.

Tensile Strength : 80,000 psi

...more

Grinding Media

Grinding Media We manufacture steel grinding media in various alloy steel compositions, shapes and sizes for diverse grinding and milling applications. This grinding media for ball mills, pulverizers and attritors is cold forged and ground. The hardened steel balls (shots, beads) are available in different hardness, as required, in both high carbon steel and chrome alloy steel. Precise heat treatment insures their resistance to flaking, chipping or spelling.Hardened steel forged grinding media is very suitable wherever high wear and chemical resistance is required. And also where generation of heat is crucial to the milling and dispersion process. The steel shots, balls and beads - ball mill media - are preferred for contamination free and speedy (dry / wet) milling, grinding of solids, liquids dispersion and fine particle size reduction, homogenization of fillers and raw materials, attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and small-media mills, vertical or horizontal.Alloy steel media is particularly suitable because of its high relative density and hardness, for crushing and mixing heavy & hard materials. And also where high pressure and impact grinding or crushing methods are employed. The forged steel media balls also find advantage in reducing particle size and fine dispersion of highly viscous fluids. Our grinding media are manufactured in carbon steel and chrome alloy steel. Normally, carbon steel balls are used for common low speed grain grinding such as metal or chemical powders. For high speed ball mill grinding process such as paints, inks or resin powders, chrome alloy steel balls are usually used for extended durability.Since grinding media are always consumed in a great volume, cost and durability become the most important characteristics sought. We have been concentrating on developing cheap but durable grinding media for many years and are now able to provide the most cost saving and most durable grinding media in the market. We supply our grinding media in various finishes and shapes to save every penny. Our special heading and heat treating processes guarantee a much better durability. We will be pleased to develop custom made grinding media for any special grinding process. AdvantagesSteel grinding media finds advantage where: High wear and chemical resistance is required. Generation of heat is crucial to the milling and dispersion process. Contamination free and speedy (dry / wet) milling is important. Crushing and mixing heavy and hard materials is undertaken. High pressure and impact grinding or crushing methods are employed. Reducing particle size and fine dispersion of highly viscous fluids is required.

...more

Eclipses Spherical steel balls

Spherical steel balls with slight flattening at the poles are recommended wherever exact roundness is not essential, as in many grinding and steel media finishing processes. Spherical steel balls because of their excellent rolling action are most commonly used shape for polishing and grinding media. However, in some polishing applications where the component profile is not flat, the rolling of spheres is interrupted. Hence, steel spheres and eclipses provide similar results. In other applications where high luster is not required, use of eclipses is preferred. The advantage of using steel eclipse balls is its cost-effectiveness i.e., cost of an eclipse is substantially lower than spherical steel balls.

...more

Spherical steel balls

Steel angle cut cylinders, bevelled diagonals and pins are mixed with steel balls, eclipses, balcones and satellites in the steel polishing media for various mass finishing applications to achieve uniform cleaning, metal finishing and mirror finish all over the component profile.Spherical steel balls are the most popular and versatile shaped media used in tumblers, barrels, harperizers, centrifugal and vibratory finishing machines. However, a round steel ball cannot access grooves, corners, collars and intricate profiles. To achieve this, a beveled diagonal (cylinder) or pin has to be used. Pins are also appropriate for deflashing holes and finishing intricate jewellery parts

...more

Chrome Steel Balls

Carbon Steel Balls

Bicycle Steel Ball

bearing balls

Feature : they demonstrate an extremely low level of running noise.

Material : carbon chrome steel

Balcones Round steel balls

Balcones or Satellites (variously called saturn, sputnik, planet, UFO) are mixed with round steel balls and other steel burnishing media (diagonals, pins, eclipses) to achieve overall cleaning, consistent metal polishing and excellent mirror finish all over the component profile.Round steel balls are most widely used shape in steel media. However, it is not always versatile, as a sphere cannot access corners. It is also unable to make contact in grooves or recesses if the steel ball diameter is larger than the groove width. In such cases, milky areas become apparent on the component surface where balls are unable to provide polishing action. Steel ballcones and satellites works very well in such areas for providing uniform finishing results

...more

non ferrous balls

Be first to Rate

Rate ThisOpening Hours