ACSR Conductors

These are concentrically stranded conductor with one or more layers of hard drawn 1350-H19 aluminium wire on galvanized steel wire core. The core can be single wire or stranded depending on the size. Steel core wire is available in Class A, B or Class C galvanization for corrosion protection. Additional corrosion protection is available through the application of grease to the core or infusion of the completed conductor with grease. The core can be single wire or stranded depending on the size of the conductors. The proportion of steel and aluminium in an ACSR conductor can be selected based on the mechanical strength and current carrying capacity demanded by each application. ACSR conductors are recognized for their record of economy, dependability and favorable strength / weight ratio.

...more

Aerial Bunched Cable

1.1 KV Volt Grade, are used for distributing power to individual consumers by utility service providers such as electricity boards and electricity distributing authorities’ cables are suspended overhead using electrical poles. The cables can be tapped intermittently from any required position, enabling them to be used in urban as well as rural areas.

...more

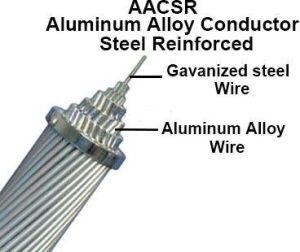

AACSR Conductor

is a concentrically stranded conductor composed of one or more layers of Aluminium-Magnesium-Silicon alloy wire stranded with a high-strength coated steel core. AACSR Conductors have approx. 40% to 60% more strength than comparable standard ACSR with only 8 to 10% decrease in conductivity. AACSR is available with steel core of Class A, B or C galvanizing or Aluminium clad (AW). Additional corrosion protection is available through the application of grease to the core or infusion of the complete cable with grease.

...more

AAC Conductor

Is made up of one or more strands of hard drawn 1350 aluminum. These conductors are used in low, medium and high voltage overhead lines. The EC grade Alloy Conductor has a minimum conductivity of 61.2% IACS. AAC has seen extensive use in urban areas where spans are usually short but high conductivity us required. The excellent corrosion resistance of aluminium has made AAC a conductor of choice in coastal areas. Because of its relatively poor strength to weight ratio, AAC had limited use in transmission lines and rural distribution because of long spans utilized. FEATURES: · High current carrying capacity. · Suitable for low and medium voltage lines in urban area Excellent resistance to corrosion · Ideal for use in coastal area

...more

AAAC Conductor

Are made out of high strength Aluminium-Magnesium-Silicon Alloy. OSWAL manufactures and supply AAAC with different variants of electrical grade alloy type 6101 and 6201. one or more strands of hard drawn 1350 aluminium alloy. As compared to conventional ACSR, AAAC are of lighter weight, comparable strength & current carrying capacity, lower electrical losses and superior corrosion resistance, this has given AAAC a wide acceptance in the distribution and transmission lines. This conductor has a minimum conductivity of 52.5% IACS.

...moreBe first to Rate

Rate ThisOpening Hours