Double Drum Magnetic Separator

245,000 Per Piece

1 Piece (MOQ)

Copper Coated Rollers

2,500 - 6,500 Per Piece

1 Piece (MOQ)

Best Deals from Conveyors

HDPE Plant Roller

Get Price Quote

10 Piece (MOQ)

High-Density Polyethylene (HDPE) Plant Rollers High-Density Polyethylene (HDPE) plant rollers are commonly used in various industrial applications, particularly in material handling and conveyor systems. HDPE plant rollers are typically made from high-density polyethylene, a thermoplastic polymer with a high strength-to-density ratio. Material:- HDPE (High-Density Polyethylene): HDPE is a thermoplastic polymer known for its high strength, durability etc. Diameter: The diameter of HDPE plant rollers can vary based on specific application requirements. Common diameters range from a few inches to several feet. Length: The length of the rollers depends on the design of the conveyor system. we can make Longer rollers for broader conveyor systems. Bearing Type: Rollers may have integrated ball bearings, which reduce friction and facilitate smooth rotation. The type and quality of bearings can vary, and sealed bearings are often preferred for protection against contaminants. Shaft: The shaft of the roller is typically made of stainless steel.It provides support and ensures proper alignment of the roller. Tube Thickness: The thickness of the HDPE tube depending on the load-bearing requirements of the application. Temperature Resistance: HDPE has a wide temperature operating range, but specific formulations may be designed for enhanced temperature resistance, especially in extreme environments. Load Capacity: The load capacity of the rollers depends on the design, diameter, and material specifications. We choose to make rollers that can handle the expected load in a given application. Surface Finish:The surface finish of the HDPE roller may be designed to minimize friction and wear. Smoother surfaces can contribute to better conveyor system performance. Color: Generally we make Green and Grey colour rollers. It's important to note that specific requirements may vary based on the industry, application, and environmental conditions. For more details please consult us. Customers:- Punjab plasto, Deesh Plastics chaheru, Vardhan packaging, Aarti packaging etc

Pizza Ovens

15,000 Per Piece

1 Piece(s) (MOQ)

Pizza ovens in difernt sizes availaible .IN All steel versions 4 pizza 8 pizza & also in conveyer oven.

CI Belt Type Drum Pulley

Get Price Quote

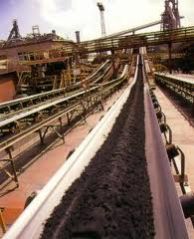

Rubber Conveyor Belts

Get Price Quote

Conveyor belts generally consist of cover rubber, carcass and rubber skim coat. The reinforced breaker fabric is used for extra protection.COVER RUBBER :Covers of natural or synthetic rubber are designed to protect the carcass from -abrasion, impact, deterioration and other injurious influences. They are compounded to meet particular service conditions such as abrasion, oil, heat, fire, chemical resistant and antistatic, etc. CARCASS :Carcass of a belt maintains the belt tension and supplies structural strength; it does all of the work in supporting and pulling the load. Carcass consists of multiple plies of rubber impregnated fabric bonded with friction and skim coats. The fabrics most commonly used are; nylon, polyester and cotton.RUBBER SKIM COAT :Â An extra layer compound between plies that increases flex life and creates a more elastic link so that plies flex without separation. Skim coats cushion fabrics against impact and help protect against moisture. BREAKER FABRIC :A specially woven fabric between the cover and the carcass to improve adhesion and provide better resistance to cover stripping, gouging or tearing. This is normally used in belts handling primarily crushed and sized material which gives great impact to the belt when lumps drop at a loading point. COMPOUND AND USAGE :The cover rubber determines belt life and the selection of the correct cover rubber grade and thickness is most important.HEAT RESISTANT CONVEYOR BELT :In general, it is economical to adopt a heat resistant belt if the temperature of the material to be carried is over 60 C (140 F). As the damage of cover depends on the temperature and nature of transported material, the proper selection of a belt to fit particular operating conditions is important. Especially the relation of temperature between the material and belt surface should be considered when selecting the belt.When transporting material of high temperature of belt surface rises by contact with the material, but on the return journey the heated surface gets cooled naturally by air so that the surface temperature becomes considerably cooler than that of the material. The temperature depends on kind, size, temperature quantity of material to be carried, belt speed, belt length and etc. This belt is designed for transporting cement clinker, cokes, sintered ores, soda ash, chemicals, fertilizer and etc.ABRASION RESISTANT CONVEYOR BELT :Material being carried as well as idlers and frame of the conveyor may cause excessive wearing on normal belts. To prolong the life of the belts running under severe wearing conditions, special and super abrasion rubber is compounded for the belt covers.OIL RESISTANT CONVEYOR BELT :Oily material causes the ordinary rubber covers of the belt to swell and peel off, which results in a complete breakdown in the conveyor system. This belt compounded of oil-resistant -quality synthetic rubber has good resistance to the damaging effects encountered when conveying oil or oily materials. FIRE RESISTANT CONVEYOR BELT :This belt is a prerequisite to prevent fire risks in coal mines where not easily accessible and to reduce maintenance of the conveyors which may be damaged by flame at the blast furnaces of iron works. ANTI-STATIC CONVEYOR BELT :This belt is made especially for use where, for instance in the paper or textile mills, the products being carried stick to the belt surface, or fire risks may be involved due to electro-static sparks.

Rubber Conveyor Belt

Get Price Quote

Grade M-24 conforming to IS:1891 (Part I) 1988 is suitable to withstand high resistance to cutting, tearing etc. In heavy duty applications for highly abrasive materials like metallic ores, coke, stone, rocks etc.Grade N-17 conforming to IS:1891 (Part I) 1988 is recommended to carry moderately abrasive materials as coal, fine ores, cement, sand etc.

Rubber Conveyor Belt

Get Price Quote

Rapid industrialization has necessitated the use of conveyor belts which have proved to be the most cost-effective system for transportation of raw material & finished goods in any form, for any application super champion belting are manufactured in our most modern, plant, using the finest raw material inputs, under the strict vigil of qualified technical personnel. Our belts have found satisfactory customers in the domestic and the international export market with our clientele ranging iron & steel plants, coal, copper, gold mines, cement plants, thermal plants, fertilizers plant our conveyor belts conform to all relevant indianinternational standards and are manufactured in a wide range to suit all applications

HR grade conveyor belt

2,500 - 3,200 Per Meter

100 Meter (MOQ)

Steel Cord Rubber Conveyor Belts

Get Price Quote

We are engaged in manufacturing, exporting and supplying Steel Cord Rubber Conveyor Belts. Our Steel Cord Rubber Conveyor Belts consist of galvanized steel cord and core rubber which possesses superior adhesive property. Their body is covered with top and bottom rubber layers. Steel cord of our belts is composed of left and right twisting wire. It is arranged evenly and longitudinally in the belt. We make available our Steel Cord Rubber Conveyor Belts in various strengths and specifications at highly competitive prices. Availability : Up to 2400 mm width Types of Cords used High Carbon Steel cords Zinc coated to ensure superior bonding between Cord and Rubber and prevent corrosion Cord configurations available : 7 *7 , 1*19+7*7 , 7*19 etc

Heat Resistant Conveyor Belt

Get Price Quote

We manufacture and supply Heat Resistant Conveyor Belts. These belts are stringently tested to comply with industrial standards. These comes in various specifications and can be customized as per client's needs and demands. We manufacture general purpose conveyors under two grades:HR (Heat Resistant): Suitable for transporting hot materials. Up to 125°C for coarse materials & 100°C for fine materials). Used to carry hot coke, foundry sand, iron pallets, sintered ore, hot lime stone, cement, clinker soda ash.) SHR (Semi-Heat Resistant): Suitable for transporting hot materials. Up to 150°C for coarse materials & 125°C for fine materials).

Seven Deck Cooling Conveyor

Get Price Quote

Spring Divider

Get Price Quote

Description :-This handy caliper/divider is great for marking, finding centers and making circles. Adjustment is made using a quick-adjust split nut. High quality manufactured and durable.

Flat Transmission Belts

Get Price Quote

We are highly acclaimed as the Manufacturer, Exporter & Supplier of Flat Transmission Belts from Punjab, India. Used for various applications, the high strength flat belts include belts for power transmission from both sides and single side. Customers can also avail belts with grooves for high load and power transmission requirements. We ensure timely delivery of the Spindle Tape to buyers. Salient Features : High abrasion friction covers for long service life. Different surface structures for maximum performance under normal and adverse running conditions. Oil and chemical resistance. High energy efficiency.

Spring Divider

Get Price Quote

Description :- This handy caliper/divider is great for marking, finding centers and making circles. Adjustment is made using a quick-adjust split nut. High quality manufactured and durable.

Food Grade Rubber Conveyor Belt

Get Price Quote

Food Grade Rubber Conveyor Belt offered by us, is manufactured with FDA approved polymers, which ensure high durability. Our entire range of Food Grade Rubber Conveyor Belts is manufactured as per international standards. These belts have white rubber covers that do not impart odour and do not stain the materials, which are conveyed. Advantages Abrasion resistant Antistatic Oil resistant High performance Longer working life Suitable For Food processing industries Pharmaceuticals industries

Continous Conveyer Shot Blasting Machine

300,000 - 500,000 Per Piece

Fire Resistant Conveyor Belt

Get Price Quote

1 Piece (MOQ)

Grade Fire resistance confirming to IS;189 (Part 5) belting is specially meant to prevent the fire risk in coal mines & thermal power stations, where fire hazards exist. The important characteristics of this grade is self-extinguishable rubber cover , FR Grade belts are manufactured as per IS standard [(IS:1891) (Part5)]. Canadian standard [CAN/CSA/M-422/M87] and ISO 340.

Lattice Conveyor Belts

Get Price Quote

Roller Conveyor Type Shot Blasting Machine

Get Price Quote

Accurately designed Roller Conveyor Type Shot Blasting Machine can be procured from us at very reasonable prices. Our machine is inline continuous roller conveyor type. We manufacture this machine using top class raw materials. Our Roller Conveyor Type Shot Blasting Machine is ideal for scaffolding pipes, plates, etc.

Rectangular Waste Bin Chute

Get Price Quote

Conveyor Belt Fastener

Get Price Quote

NN / EP Conveyor Belts

Get Price Quote

NN EP Conveyor Belts Compounded premium from premium quailty natural rubber to provide excellent resistance to cutting gouging,

plastic machine rubber roller

Get Price Quote

Rubber rollers for the following plastic machinery rubber rollers Bag manufacturing and sealing machine rubber rollers Flexo machine rubber rollers Roto graver rubber rollers.Plastic sheet rubber rollers, Plastic printing rubber rollers, Packing machine rubber rollers

Food Grade Conveyor Belts

Get Price Quote

These hygienic conveyor belts do not stain and odorize the materials to be conveyed and widely used in the food industries for appropriate handling of food stuffs, pharmaceutical industries. Our range of hygienic belts is stringently quality checked to ensure that they are free from any kind of defect.

MTS Conveyor Belts

Get Price Quote

Width: 300 mm to 1800 mm in steps of 50 mm. Length : Open or endless upto 200 mtrs in single length Fabrics plies : 2 plies to 8 plies Fabrics : Polyster Nylon (EP) EP 100, EP 125, EP 150, EP 200, EP 250, EP 300, EP 350 , EP 400 and EP 450 Nylon Nylon (NN) NN 100, NN 125, NN 150, NN 200, NN 250, NN 300, NN 350, NN 400 and NN 450. Cotton Cotton 28 OZ, 32 OZ, 36 OZ, 42 OZ, 48 OZ and for elevator belts 34 OZ. X Mechanical Fasteners not recommended.For Specific requirements not covered in above table, please contact with details. The figures mentioned above are approximate values for consideration for drive design. and are subjected to change without notice in the make of fresh developments. Cover Grades : Cover type Tensile strength Elongation at break General Applications Specific. Kg/cm2 (Min.) (% Min.)M-24 240 450 Suitable for rugged services for conveying crushed Metallic ores, Lime stone, Granite etc. Also suitable for large size ores. IS-1891, (Part-I)-1994 N-17 170 400 Suitable for Materials, like Asbestos, Ash, Bauxite, Cement lime etc. IS-1891, (Part-1)-1994 HR(T1) 125 350 Suitable for Transporting hot material (Upto 125oC for coarse material and 100oC for fine material) IS-1891, (Part 2) SHR(T2) 125 350 Suitable for transporting hot material (Upto 150oC for coarse material and 125oC for fine material) IS-1891, (Part 2) OR (Oil Resistant) 120 250 Cover Grade of specially blended synthetic Polymers is designed to give very high resistance to mineral vegetables and Animal Oils & Fats. IS-1891, (Part 3) FR (Fire Resistant) 170 350 Recommended for use in surface applications in coal and such type of mines where the ambient temp. may not be high but there is distinct hazard of belts being enveloped in fire. Rubber covers are fire resistant and anti static. CAN/CSA/M-422/ M-87 & IS-1891 (Part 5) Covers thickness : 1mm to 12mm in steps of 0.5 mm Type of Edges : Available in cut edges and moulded (protected) edges. Skim coated : The belts are processed with its all fabric plies skim coated with superior quality rubber compounds Mildew inhibition : The rubber compounds used in the belts are designed such as to have full protection against mildew Breaker Ply: To with stand extra impact during service the belts are provided with breaker ply on demand. Belt Designation: Available in three types i.e. General Duty (GD), Heavy Duty (HD) and Extra Heavy Duty (EHD). Apart from straight ply construction the belts are offered in Stepped ply as well as Reverse stepped ply constructions also. National and International Standards followed : 1. Bureau of Indian Standards BIS 2. British Standards BS 3. International Organisation for Standardization ISO 4. German Standards DIN 5. Canadian Standards CBM 6. Australian Standards ASS 7. France Standards NF-T47-100/101 Special features of MTS Conveyor Belts : 1. Unique Carcass Design & Assembly. 2. Superior Adhesion Levels. 3. Higher Longitudinal Flexibility. 4. Improved Transverse Flexibility. 5. Higher Tensile Strength. 6. Low Belt Stretch. 7. Outstanding Impact Resistance. 8. Improved resistance to mechanical damages. 9. Higher carrying capacity with low belt weight. 10. Rot Resistance. 11. Hot & cold splice proven. 12 Superior joint efficiency & increased life. 13. Universal applications.14 Resistance to environmental operating condition.15. Smooth & trouble free service.

General Purpose Conveyor

Get Price Quote

We manufacture and supply General Purpose Conveyors. General purpose conveyors are manufactured under two grades: M-24 Grade N-17 Grade

PVC Conveyor Belts

15,000 - 4,000 Per Square Meter

Hot Air Oven

Get Price Quote

Engineering Equipment

Get Price Quote

Doming punchs and block description :- these professional quality doming punchs and blocks are used for shaping, forming and chasing metal in dapping blocks. The complete set 40 pcs. Doming punchs, block and polished wooden stand for easy storage and identification. Code sizes 294d doming punchs and block (40 pcs. Set)