fabric belts

Get Price Quote

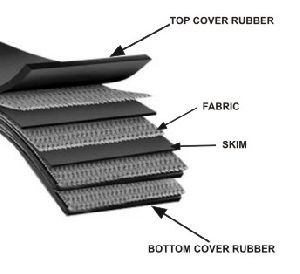

neelkanth belts are manufactured with a variety of fabrics like cotton/cotton, cotton/nylon and synthetic fabrics like nylon/nylon grade n6 or n66 and polyester/nylon (ep) our fabric belts are perfect combination of quality raw material, modern technology,experienced manpower and elaborate quality assurance measures. Neelkanth conveyor belts have high adhesion levels,special chemical bonding techniques ensure very high adhesion levels between cover to ply and ply to ply, achieving superior belt consolidation and higher peel resistance. High adhesion levels and presence of thick rubber cushions between plies provides outstanding impact resistance and eliminates cover stripping and ply to ply delamination. Our belts give higher transverse flexibility which allows deeper troughing,improving volumetric transfer capacity of conveyors. At the same time , higher longitudinal flexibility allows use of smaller pulleys diameter and reduces flex fatigue. width upto 2500mm length open or endless plies 3 to 7 plies cover thickness upto 40mm tensile strength upto 2500 kn/m types of synthetic carcass general duty (gd), extra duty (ed) & heavy duty (hd) edges cut edge or moulded edge breaker ply breaker is provided on face, back and edges as per customers requirement ply construction straight ply, stepped ply and reversed stepped ply. fabric specification (i) cotton/cotton fabric - the conventional cotton/cotton fabrics used are 28oz, 32oz, 36oz, 42oz & 48oz(ii) cotton nylon fabrics - the belts with cotton nylon fabrics have higher carrying capacityas they trough more than cotton fabric belts. The cotton nylon fabrics are cn40, cn50, cn60, cn70, cn75, cn90, cn100, cn130, cn150(iii) synthetic fabric - the synthetic fabrics are the most effective reinforcement for conveyor belts. The extra strength and controlled rigidity obtained from synthetic fabric carcass combined with high levels of ply to ply adhesion enable less bulky constructions to be employed compared with conventional cotton/cotton or cotton/nylon fabrics. The belts with synthetic fabric carcsss offers a longer service life with improved performance under arduous conditions. skim coating skim coating is offered as standard construction in nylon/nylon, polyester/nylon carcass.

NYLON FABRIC BELTING

Get Price Quote

Friction surface material is NBR film. Back surface material is NBR film.The belt factor is 2 N/mm at 1% elongation for product code MTS 20F, 4 N/mm for MTS 40F, 6.50 N/mm for MTS 80F.

Best Deals from Fabric Belt

fabric belts

Get Price Quote

fabric belts, conveyor fabric belts, Rubber Conveyor Belts, Rubber Sheet