Vertical Tapping Machine

Itco INDIAN ENGG CORP is catering a wide scale of high speed Tapping Machine as a Manufacturer, Exporter & Supplier in INDIA. These Precision Tapping Machines are very successful in mass production of internal threading jobs. Any type of internal thread i.e. MetricBsw, LHRH can be tapped on this universal tapping machine by referring the Tap and Drill chart. The feed is given manually by hand and there is no tap breakage in these vertical tapping machines due to friction clutch assembly. A wide range of spindle speed is provided for machining different tap sizes. Only high speed steel machine tap’s are recommended along with appropriate tapping lubricant selected on the basis of material to be tapped. Machine Taps can be holded either in chuck or directly in machine spindle by using tap sleeves. Working of clutch type tapping machine is very simple, the forward and reverse rotation of spindle is done by means of taper cones and friction clutch assembly. Itco Tapping machines are very robust in design and have long operating life. Due to its simple operation, low energy consumption and high performance these high speed tapping machines find their application in almost all types of industries like, sheet metal, plastic switch gear, electronics and other allied non ferrous products.

...more

Pillar Type Drilling Machine

Located in Punjab (India), we are leading global manufacturersupplier of Precision Engineered Heavy duty Itco Drilling Machines & Tapping Machines. The unit is equipped with state of the art best Drilling Machine tools facilities and fully integrated to provide customers online with a one stop resource for shopping Sensitive Drilling and Tapping machines at an industry leading price. Our capability to offer world class technology Drilling machine tools in india at competitive prices backed with effective after sales service provides a significant advantage to our customers. Our product range includes a wide technical specifications of following types of vertical Drilling Machine & Tapping Machines: Bench Drill Machine, Pedestal Drilling Machine, Pillar Drilling Machine, Column Drill Machine, Geared type Drilling machine, Upright Drilling Machine, Drilling cum Tapping Machine,Automatic Drilling Machine, Auto feed Drilling Machine, Hydraulic & Pneumatic feed Drilling Machine, Precision Drill Machine, High Speed Tapping Machine, Pitch control Tapping Machinr, Gear type Automatic Tapping Machine, Gang Drilling Machine, Multi Spindle Drilling Machine, itco machine tools, special purpose machines with standard module of drilling & tapping machine configured to meet custom requirements.

...more

Multi Spindle Drilling Machine

ITCO PRECISION TAPPING MACHINES

Itco INDIAN ENGG CORP is catering a wide scale of high speed Tapping Machine as a Manufacturer, Exporter & Supplier in INDIA. These Precision Tapping Machines are very successful in mass production of internal threading jobs. Any type of internal thread i.e. Metric/Bsw, LH/RH can be tapped on this universal tapping machine by referring the Tap and Drill chart. The feed is given manually by hand and there is no tap breakage in these vertical tapping machines due to friction clutch assembly. A wide range of spindle speed is provided for machining different tap sizes. Only high speed steel machine tap’s are recommended along with appropriate tapping lubricant selected on the basis of material to be tapped. Machine Taps can be holded either in chuck or directly in machine spindle by using tap sleeves. Working of clutch type tapping machine is very simple, the forward and reverse rotation of spindle is done by means of taper cones and friction clutch assembly. Itco Tapping machines are very robust in design and have long operating life. Due to its simple operation, low energy consumption and high performance these high speed tapping machines find their application in almost all types of industries like, sheet metal, plastic switch gear, electronics and other allied non ferrous products. TM 6 is a Bench type Tapping Machine with Jacob taper type spindle for holding drill chuck. The Base plate has three holes for fixing the machine on a platform/table.TM 13 is a Pillar type Tapping Machine with Morse taper (self holding taper) spindle. The Base plate has four holes for grouting (foundation). SALIENT FEATURES Precision Tapping machines meets mass production Tapping requirement for instrumentation, sheet metal, electronics and other allied industries. These machines are simple to operate. Tapping is done at high speeds and gives max production output . The Friction clutch assembly is designed to give instantaneous control to change the rotation of tap without motor reversal. Tap breakage is reduced to absolute minimum. Useful for single, batch, mass productions without any change in setting. Special Quality Friction clutch for longer life. Spindle is made of alloy steel accurately machined and ground. Spindle Runout at final testing 20 to 30 microns. Head is made from close grained CI, accurately bored and honned o ensure perfect parallelism between the column and spindle. A precision ground column is made from Heavy section Seamless steel tube which ensures rigidity and resists deflection. Square Table is accurately machined for precision work. All moving parts are accurately machined & ground. Useful for both RH & LH Threading and fine depth accuracy even in blind holes. Machine Accuracy as per IS-6175.

...more

Gang Drill Machines

Itco INDIAN ENGG CORP stand among best Manufacturer, Exporter & Supplier of multiple types of Precision Vertical Drilling Machines & Gang Drill Machines special purpose as per custom requirement. Different sizes of drilling heads & tapping heads are mounted on a single platform/ table. Gang Drilling Machines are suitable for mass production of a component ensuring high performance and better productivity. The various machining operations like drilling, reaming, counter drilling, tapping etc are identified and accordingly the selection of drilling/ tapping heads is done. For machining operations where coolant is required, an independent complete coolant system can be integrated with these special purpose vertical drilling machines. These multiple heads are mounted on independent pillars/ columns spaced conveniently. The working base is accurately machined and hand scrapped for optimum finish. For fixing the drilling jig T-Slots are machined on the working base. Requirement of Power for Gang Drilling Machine is calculated on the basis of number of heads mounted. Sliding table can be mounted on the working base for indexing the job (without unclamping) between various drill stations. Indexing is done either manually by hand feed or Automatic indexing by means of hydraulic /pneumatic feed. SALIENT FEATURES Precision Drilling Machines are suitable for Drilling, Boring, Reaming, Spot Facing & Tapping operations of mass production jobs. Spindle Is made of alloy steel accurately machined & ground, concentric to Precision ground alloy steel Quill supported in 2 Nos Taper Roller Bearings. In model (PDM-18 & 20) Spindle has 4 splines as per machine tools splines standard and drives through broached sleeve. In model (PDM-25) Spindle has 6 splines as per machine tools spline standard and drives through broached sleeve. Properly balanced spindle pulley is mounted on Double Ball Bearings with Bracket support for absorbing V-Belt Load. Spindle MT Bore Accuracy 20 to 30 microns. Head is made from close grained CI, accurately bored and honed to ensure perfectly parallelism between the column & spindle. The Quill carrying spindle is precisely ground to slide in accurately honed bore. A Precision ground column is made from heavy section seamless steel tube, ensures rigidity and resists deflection. Base is accurately machined & Hand Scrapped with an accuracy of 20 to 30 microns. Machined T-Slots are provided for clamping the work piece. All moving parts are accurately machined & Ground. Precision Drilling Machine Accuracy as per IS-2425.

...more

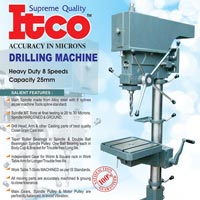

ITCO PILLAR DRILLING MACHINES

Itco INDIAN ENGG CORP is famed Pillar Drilling Machine Manufacturer, Exporter & Supplier in Punjab (INDIA). Drill Machine price tendered is very prudent in contrast to high quality of workmanship. The Drill Press offered are very heavy duty, made of high grade raw materials, developed using hi tech machines & technologies online with the latest industry standards . These Vertical Drill Machines find their application in almost all major industrial jobs: auto parts, hand tools, tool rooms, all types of production jobs and special purpose jobs etc. Working of Drilling machine is very simple and is ideal for metal drilling, wood drill, pipe drilling operations. Clients can select these sensitive drilling machines on the basis of pillar/column diameter, capacity of drilling, range of spindle speeds, power requirement etc. Pillar type drill presses are similar to bench type drill press but are of larger in size with higher drilling capacity and more powerful. While Bench drill press are fixed on a table, pillar drill presses are grouted to floor (foundation). Pillar drill machines are also know as stand drill machine. Standard Drill sizes upto 20mm in steel can be drilled with these machines. Precision Pillar Drill machines are available in self holding taper (MT-2). SALIENT FEATURES Spindle Is made of alloy steel accurately machined & ground, concentric to Precision ground alloy steel Quill supported in 2 Nos Taper Roller Bearings. Spindle has 4 splines as per machine tools splines standard and drives through Broached Sleeve. Properly balanced spindle pulley is mounted on Double Ball Bearings with Bracket support for absorbing V-Belt Load. Spindle MT Bore Accuracy 20 to 30 microns. Head is made from close grained CI, accurately bored and honed to ensure perfectly parallelism between the column & spindle. The Quill carrying spindle is precisely ground to slide in accurately honed bore. A Precision ground column is made from heavy section seamless steel tube, ensures rigidity and resists deflection. Square Table is accurately machined for precision work. 2 Nos of Machined T-Slots are provided for clamping the work piece. All moving parts are accurately machined & Ground. Pillar Drilling Machine Accuracy as per IS-2425.

...more

ITCO GEARED TYPE PILLAR DRILLING MACHINES

Itco INDIAN ENGG CORP flourish as an expertise in precision Geared type Pillar Drilling Machine Manufacturer, Exporter & Supplier in INDIA and abroad. These Pillar Drill Presses are designed for both industrial mass production components and Tool room jobs. A wide range of machining operations like drilling, reaming, boring, spot facing etc can be performed successfully on these industrial pillar drills. Features like streamlined design with compact construction, wide range of spindle speeds, heavy duty pillar/column section, accurate table with machined T-slots for fixing drill vice, interchangeability of all the spares parts, grounded self holding taper of drill spindle fitted with precision taper roller bearings etc. Workmanship/ Quality of our Pillar Drill stand us apart from our competitors. Heavy duty Pillar drill press machine can also be used for drilling mini/small drills with straight shank held in drill chuck. There are four holes drilled on the base plate for foundation on the floor standing pillar drill. For safety of the operator from drill chips, guard can be fitted as an additional accessory. These Vertical drilling machine are offered at an industry leading prices. Easy back gear engagement gives slow speed range required for various drilling operations like, reaming, chamfering, Tapping, counter drilling etc. Gears are accurately machined/ ground & fitted with sintered bushes for automatic continuous lubrication. These gears when engaged produces very less noise/vibration ensuring an accurate & precise work. Geared type Drilling machines are preferred when the hole sizes vary and ease of speed change is desired. SALIENT FEATURES Geared type Pillar Drilling Machines are suitable for Drilling, Reaming, Boring and Spot facing and has 8 spindle speeds. Spindle Is made of alloy steel accurately machined & ground, concentric to Precision ground alloy steel Quill supported in 2 Nos Taper Roller Bearings. In model (DM-20-8) Spindle has 4 splines as per machine tools splines standard and drives through broached sleeve. In model (DM-25) Spindle has 6 splines as per machine tools spline standard and drives through broached sleeve. Properly balanced spindle pulley is mounted on Double Ball Bearings with Bracket support for absorbing V-Belt Load. Spindle MT Bore Accuracy 20 to 30 microns. Head is made from close grained CI, accurately bored and honed to ensure perfectly parallelism between the column & spindle. The Quill carrying spindle is precisely ground to slide in accurately honed bore. A Precision ground column is made from heavy section seamless steel tube, ensures rigidity and resists deflection. Square Table is accurately machined for precision work. 2 Nos of Machined T-Slots are provided for clamping the work piece. All moving parts are accurately machined & Ground. Geared type Pillar Drilling Machine Accuracy as per IS-2425.

...more

Drilling Machine

We are offering geared type pillar drilling machines are suitable for drilling, reaming, boring and spot facing and has 8 spindle speeds. spindle is made of alloy steel accurately machined & ground, concentric to precision ground alloy steel quill supported in 2 nos taper roller bearings. In model (dm-20-8) spindle has 4 splines as per machine tools splines standard and drives through broached sleeve. in model (dm-25) spindle has 6 splines as per machine tools spline standard and drives through broached sleeve. properly balanced spindle pulley is mounted on double ball bearings with bracket support for absorbing v-belt load. spindle mt bore accuracy 20 to 30 microns. head is made from close grained ci, accurately bored and honed to ensure perfectly parallelism between the column & spindle. The quill carrying spindle is precisely ground to slide in accurately honed bore. a precision ground column is made from heavy section seamless steel tube, ensures rigidity and resists deflection. square table is accurately machined for precision work. 2 nos of machined t-slots are provided for clamping the work piece. All moving parts are accurately machined & ground. geared type pillar drilling machine accuracy as per is-2425.

...more

Drilling Machine

We are offering drilling machine 20mm. Itco indian engg corp is leveraging on wide industrial expertise of manufacturing, exporting, and supplying geared type pillar drilling machine in india and abroad. Designed for both mass production and tool room jobs the versatility of drilling machine gives the wide range of operations and is efficient in drilling, reaming, spot facing and boring. These drilling machines offer streamlined design with compact construction and wide range of spindle speeds.

Brand Name : itco

...more

ITCO DRILLING CUM TAPPING MACHINES

Itco INDIAN ENGG CORP is manufacturing, exporting & supplying state of art Drilling cum Tapping Machine in INDIA & abroad. These Tap Drill machines are custom designed and fitted with special best quality bearings. Reliable branded electrical components are fitted in tapping attachment / electrical panel for economical high precision production of drilling and tapping operation. This Universal Tapping machine is suitable to tap any type of thread inside a vertical hole. One can do threading in Metric or BSW threads, Left Hand (LH) or Right Hand (RH) threads depending upon the machine tap selected. Tapping Drill sizes are selected from drill and tap chart. Working of this electric tapping machine is very simple. There are two limit switches operated by means of an adjustable cams which are used for Tapping in blind holes. While tapping through holes foot control switch is provided. These are semi automatic tapping machine i.e. the operator has to bring the tap towards the hole by manual action and once few threads are cut (1 to 2 nos) no further hand feed is required and the tap automatically advances towards the depth set and withdraw back successfully to home position. To switch between drilling and Tapping process mode a selector switch is provided. Machining of External threads is also possible by using a special purpose tapping tool. These Vertical Tapping machines are simple to operate, very accurate and offers a unique combination of drilling & tapping operation suitable for mass production/ tool room jobs. SALIENT FEATURES Drilling cum Tapping machines are Highly versatile for Tapping, Drilling, Reaming and Screwing at preset depth. Simple to install, simple to operate, no extra skill required. Dual operation of Tapping and Drilling without any extra attachment. The mere flick of switch sets the machine from Tapping to Drilling and vice-versa. Automatic reversal of spindle at preset depth and changes the direction of spindle automatically back to normal. Simple back gear arrangement facilitates 8 spindle speeds to suit the cutting speeds. Emergency reversing foot switch to avoid tap breakage. Being an electrical switch gear unit no wear and tear and hence no maintenance is required Machine Accuracy as per IS 2425

...more

Drill Machine

We are offering itco indian engg corp is counted among leading bench drill machine manufacturer, exporter, and supplier in punjab (india). We bring forth an optimum grade bench drilling machine which works with very high precision particulars size drilling capacity in steel 13mm spindle travel 87 pillar diameter 47.6 pillar length 625 distance btw centre of spindle & pillar front 150 max distance btw spindle & table 250 max distance btw spindle & base 363 table working space ø 200 base working surface (machined) 175 x 175 overall size of base 320 x 230 no of spindle speeds 4 range of spindle speeds (rpm) 640-1040-1640-2540 v belt a 36 motor 12 h.p net weight 45 kg space occupied (lxbxh) 390 x 300 x 815

...more

Itco 20mm Drill Machine

TECHNICAL SPECIFICATION: Model Itco Drilling Machine 20mm 8 speed is a heavy duty machine having drilling capacity in Steel 20mm, CI 22mm. The machine is suitable for Tapping, Reaming, Boring and Spot facing and has 8 spindle speeds. Spindle is made of alloy steel accurately machined and ground, supported in precision ground alloy steel quill carrying 2 taper roller bearings Spindle has 4 splines as per machine tool spline standard and drives through broached sleeve. Properly balanced spindle pulley is mounted on ball bearing with bracket support for absorbing V- belt load. Spindle MT bore accuracy 20 to 30 microns. Additional 4 speeds are obtained from Gear set. Head Is made from close grained CI, accurately machined to ensure perfect parallelism between the column and spindle. The quill carrying spindle is precisely ground to slide in precisely honed bore. A Precision ground Column is made from heavy section seamless steel tube which ensures rigidity and resists deflection. Square Table is accurately machined for precision work. All moving parts are accurately machined and ground. Machine Accuracy as per IS 2425 Technical Specifications DRILLING CAPACITY IN STEEL 20mm DRILLING CAPACITY IN CAST IRON 22mm MORSE TAPER IN SPINDLE MT-2 SPINDLE TRAVEL 125 PILLAR DIAMETER 72 PILLAR LENGTH 1065 DISTANCE BTW CENTRE OF SPINDLE & PILLAR FRONT 206 MAX DISTANCE BTW SPINDLE & TABLE 410 MAX DISTANCE BTW SPINDLE & BASE 785 TABLE WORKING SPACE : ROUND Ø 325 SQUARE 280 x 280 BASE WORKING SURFACE (MACHINED) 571 x 310 OVERALL SIZE OF BASE 355 x 245 NO OF SPINDLE SPEEDS 8 RANGE OF SPINDLE SPEEDS (rpm) 80-150-250-430-510-920-1590-2850 V BELT A 45 MOTOR 1H.P, 1400rpm, 3 Phase NET WEIGHT 120kg SPACE OCCUPIED (LxBxH) 710 x 430 x 1350

...more

ITCO BENCH DRILLING MACHINES

Itco INDIAN ENGG CORP is leading brand of Bench type Drill Machine manufacturer, exporter & supplier in Punjab (INDIA). We bring forth an optimum grade best Drill Machine online with very high accuracy, precision working at nadir prices. Precision Bench drilling machines offered by us are accurately machined to ensure flawless working for longer time span. All the moving parts of Bench drill press are accurately machined and ground. Owing to its compact size and simple operation one can use this mini drill machine for home use also. These mini drilling machines exhibits excellent rigidity & strength, are Vee belt driven, highly efficient, quieter running and few moving parts with potentially less possibility of breakdown. Motor rating of 0.5 horse power, 1440 rpm is required for these electric drill machine. These small drilling machine are suitable for single phase motor also. Installation of this small drill machine is very simple and they are preferably mounted on table.The oprator has to stand while working on these small/ mini drill machine belt drive bench drills machine are the best option if the holes to be drilled are of same or similar size. Bench drill press/drilling machines are available in (Jacob taper) drill chuck type/ Morse taper (self holding taper). A Morse taper spindle provides greater flexibility. This sensitive drilling machine is available in two models: In ITCO DM-13 (Red colour) Bench Drill Machine, spindle is single splined with Taper JT-6/MT-2. ITCO DM 13-HD (Blue colour) is Heavy Duty Bench Drill Machine. Spindle is 4 splined with Taper JT-6. Broached Sleeve, Quill & Quill Gear is Heavy duty. SALIENT FEATURES Spindle is made of alloy steel accurately machined and ground, supported in precision ground alloy steel quill carrying taper roller bearings. Properly balance pulley is mounted on double ball bearings. Spindle accuracy 10 to 20 microns. Head is made of close grained C.I, accurately machined to ensure perfect parallelism between the column and spindle The quill carrying spindle is precisely ground to slide in precisely honed bore. A Precision ground Column is made from heavy section seamless steel tube which ensures rigidity and resists deflection. Work Table is accurately machined for precision work. Base Plate is made of close grained Cast Iron, accurately machined working surface and is strongly webbed underneath for rigidity and strength. Two wide slots are provided for clamping the work piece. All moving parts are accurately machined and ground. Bench Drilling Machine Accuracy as per IS 2425 .

...more

ITCO AUTO FEED DRILLING MACHINES

Itco INDIAN ENGG CORP lends complete solution as a Manufacturer, Exporter & Supplier of Precision Hydraulic/Pneumatic Auto feed Drilling Machines. These Automatic Drilling Machines are ideal for Drilling, Boring, Reaming, Spot Facing operations of mass production jobs. For Customer having requirement of multiple holes drilling at single stroke, a multi spindle drilling attachment can be mounted on auto feed drilling machine. We offer complete process automation for hydraulic drilling machines through a single command i.e. by pressing a push button, auto clamping of job followed by drilling operation, auto coolant system, unclamping of job after successful completion of machining. Due to power feed cycle time is reduced considerably and results in increase in production. Owing to complete automation of process in auto feed drilling machine human effort/fatigue is reduced to minimum, need of skilled labor is eliminated and a single worker can operate more than one machine at a time. Safety of the worker is considered at foremost while designing the automatic drill machine system.In auto feed drilling machine all necessary safety equipments are installed and the process is designed by poka yoke techniques. Auto drilling machine manufactured by us are very heavy duty and sturdy in construction, perceived for its high performance and very low maintenance cost. Elements of power pack and electrical panel accessories used are of Standard make online with latest industrial standards. Auto feed Drill Machine are supplied complete with Electricals & Accessories of Standard make. SALIENT FEATURES Hydraulic autofeed Drilling cycle: rapid forward, feed, dwell, rapid return Hydraulic spindle feed infinitely variable within the range ASLC (Application specific logic controller for automation Built in coolant system Hydraulic job clamping (Optional) Variable spindle speeds within the range (Optional) Pecking cycle for deep hole drilling (Optional) User friendly operating system Single switch operation Drill bit wearing is low TECHNICAL SPECIFICATIONS

...more

Hydraulic Drilling Machine

Itco INDIAN ENGG CORP lends complete solution as a Manufacturer, Exporter & Supplier of Precision HydraulicPneumatic Auto feed Drilling Machines. These Automatic Drilling Machines are ideal for Drilling, Boring, Reaming, Spot Facing operations of mass production jobs. For Customer having requirement of multiple holes drilling at single stroke, a multi spindle drilling attachment can be mounted on auto feed drilling machine. We offer complete process automation for hydraulic drilling machines through a single command i.e. by pressing a push button, auto clamping of job followed by drilling operation, auto coolant system, unclamping of job after successful completion of machining. Due to power feed cycle time is reduced considerably and results in increase in production. Owing to complete automation of process in auto feed drilling machine human effortfatigue is reduced to minimum, need of skilled labor is eliminated and a single worker can operate more than one machine at a time. Safety of the worker is considered at foremost while designing the automatic drill machine system.In auto feed drilling machine all necessary safety equipments are installed and the process is designed by poka yoke techniques. Auto drilling machine manufactured by us are very heavy duty and sturdy in construction, perceived for its high performance and very low maintenance cost. Elements of power pack and electrical panel accessories used are of Standard make online with latest industrial standards. Auto feed Drill Machine are supplied complete with Electricals & Accessories of Standard make.

...more

hydraulic auto drilling machine

Itco INDIAN ENGG CORP lends complete solution as a Manufacturer, Exporter & Supplier of Precision HydraulicPneumatic Auto feed Drilling Machines. These Automatic Drilling Machines are ideal for Drilling, Boring, Reaming, Spot Facing operations of mass production jobs. For Customer having requirement of multiple holes drilling at single stroke, a multi spindle drilling attachment can be mounted on auto feed drilling machine. We offer complete process automation for hydraulic drilling machines through a single command i.e. by pressing a push button, auto clamping of job followed by drilling operation, auto coolant system, unclamping of job after successful completion of machining. Due to power feed cycle time is reduced considerably and results in increase in production. Owing to complete automation of process in auto feed drilling machine human effortfatigue is reduced to minimum, need of skilled labor is eliminated and a single worker can operate more than one machine at a time. Safety of the worker is considered at foremost while designing the automatic drill machine system.In auto feed drilling machine all necessary safety equipments are installed and the process is designed by poka yoke techniques. Auto drilling machine manufactured by us are very heavy duty and sturdy in construction, perceived for its high performance and very low maintenance cost. Elements of power pack and electrical panel accessories used are of Standard make online with latest industrial standards. Auto feed Drill Machine are supplied complete with Electricals & Accessories of Standard make.

...more

geared drilling machine

Itco INDIAN ENGG CORP flourish as an expertise in precision Geared type Pillar Drilling Machine Manufacturer, Exporter & Supplier in INDIA and abroad. These Pillar Drill Presses are designed for both industrial mass production components and Tool room jobs. A wide range of machining operations like drilling, reaming, boring, spot facing etc can be performed successfully on these industrial pillar drills. Features like streamlined design with compact construction, wide range of spindle speeds, heavy duty pillarcolumn section, accurate table with machined T-slots for fixing drill vice, interchangeability of all the spares parts, grounded self holding taper of drill spindle fitted with precision taper roller bearings etc. Workmanship Quality of our Pillar Drill stand us apart from our competitors. Heavy duty Pillar drill press machine can also be used for drilling minismall drills with straight shank held in drill chuck. There are four holes drilled on the base plate for foundation on the floor standing pillar drill. For safety of the operator from drill chips, guard can be fitted as an additional accessory. These Vertical drilling machine are offered at an industry leading prices.

...more

Gang Drilling Machines

Drilling Cum Tapping Machine

Itco INDIAN ENGG CORP is manufacturing, exporting & supplying state of art Drilling cum Tapping Machine in INDIA & abroad. These Tap Drill machines are custom designed and fitted with special best quality bearings. Reliable branded electrical components are fitted in tapping attachment electrical panel for economical high precision production of drilling and tapping operation. This Universal Tapping machine is suitable to tap any type of thread inside a vertical hole. One can do threading in Metric or BSW threads, Left Hand (LH) or Right Hand (RH) threads depending upon the machine tap selected. Tapping Drill sizes are selected from drill and tap chart. Working of this electric tapping machine is very simple. There are two limit switches operated by means of an adjustable cams which are used for Tapping in blind holes. While tapping through holes foot control switch is provided. These are semi automatic tapping machine i.e. the operator has to bring the tap towards the hole by manual action and once few threads are cut (1 to 2 nos) no further hand feed is required and the tap automatically advances towards the depth set and withdraw back successfully to home position. To switch between drilling and Tapping process mode a selector switch is provided. Machining of External threads is also possible by using a special purpose tapping tool. These Vertical Tapping machines are simple to operate, very accurate and offers a unique combination of drilling & tapping operation suitable for mass production tool room jobs.

...more

Bench Drilling Machines

Itco INDIAN ENGG CORP is leading brand of Bench type Drill Machine manufacturer, exporter & supplier in Punjab (INDIA). We bring forth an optimum grade best Drill Machine online with very high accuracy, precision working at nadir prices. Precision Bench drilling machines offered by us are accurately machined to ensure flawless working for longer time span. All the moving parts of Bench drill press are accurately machined and ground. Owing to its compact size and simple operation one can use this mini drill machine for home use also. These mini drilling machines exhibits excellent rigidity & strength, are Vee belt driven, highly efficient, quieter running and few moving parts with potentially less possibility of breakdown. Motor rating of 0.5 horse power, 1440 rpm is required for these electric drill machine. These small drilling machine are suitable for single phase motor also. Installation of this small drill machine is very simple and they are preferably mounted on table.The oprator has to stand while working on these small mini drill machine belt drive bench drills machine are the best option if the holes to be drilled are of same or similar size. Bench drill pressdrilling machines are available in (Jacob taper) drill chuck type Morse taper (self holding taper). A Morse taper spindle provides greater flexibility. This sensitive drilling machine is available in two models:

...more

Bench Drill

Itco INDIAN ENGG CORP is leading brand of Bench type Drill Machine manufacturer, exporter & supplier in Punjab (INDIA). We bring forth an optimum grade best Drill Machine online with very high accuracy, precision working at nadir prices. Precision Bench drilling machines offered by us are accurately machined to ensure flawless working for longer time span. All the moving parts of Bench drill press are accurately machined and ground. Owing to its compact size and simple operation one can use this mini drill machine for home use also. These mini drilling machines exhibits excellent rigidity & strength, are Vee belt driven, highly efficient, quieter running and few moving parts with potentially less possibility of breakdown. Motor rating of 0.5 horse power, 1440 rpm is required for these electric drill machine. These small drilling machine are suitable for single phase motor also. Installation of this small drill machine is very simple and they are preferably mounted on table.The oprator has to stand while working on these small mini drill machine belt drive bench drills machine are the best option if the holes to be drilled are of same or similar size. Bench drill pressdrilling machines are available in (Jacob taper) drill chuck type Morse taper (self holding taper). A Morse taper spindle provides greater flexibility. This sensitive drilling machine is available in two models:

...more

Automatic Tapping Machine

Located in Punjab (India), we are leading global manufacturersupplier of Precision Engineered Heavy duty Itco Drilling Machines & Tapping Machines. The unit is equipped with state of the art best Drilling Machine tools facilities and fully integrated to provide customers online with a one stop resource for shopping Sensitive Drilling and Tapping machines at an industry leading price. Our capability to offer world class technology Drilling machine tools in india at competitive prices backed with effective after sales service provides a significant advantage to our customers. Our product range includes a wide technical specifications of following types of vertical Drilling Machine & Tapping Machines: Bench Drill Machine, Pedestal Drilling Machine, Pillar Drilling Machine, Column Drill Machine, Geared type Drilling machine, Upright Drilling Machine, Drilling cum Tapping Machine,Automatic Drilling Machine, Auto feed Drilling Machine, Hydraulic & Pneumatic feed Drilling Machine, Precision Drill Machine, High Speed Tapping Machine, Pitch control Tapping Machinr, Gear type Automatic Tapping Machine, Gang Drilling Machine, Multi Spindle Drilling Machine, itco machine tools, special purpose machines with standard module of drilling & tapping machine configured to meet custom requirements.

...more

AUTOMATIC DRILLING MACHINE

Itco INDIAN ENGG CORP lends complete solution as a Manufacturer, Exporter & Supplier of Precision HydraulicPneumatic Auto feed Drilling Machines. These Automatic Drilling Machines are ideal for Drilling, Boring, Reaming, Spot Facing operations of mass production jobs. For Customer having requirement of multiple holes drilling at single stroke, a multi spindle drilling attachment can be mounted on auto feed drilling machine. We offer complete process automation for hydraulic drilling machines through a single command i.e. by pressing a push button, auto clamping of job followed by drilling operation, auto coolant system, unclamping of job after successful completion of machining. Due to power feed cycle time is reduced considerably and results in increase in production. Owing to complete automation of process in auto feed drilling machine human effortfatigue is reduced to minimum, need of skilled labor is eliminated and a single worker can operate more than one machine at a time. Safety of the worker is considered at foremost while designing the automatic drill machine system.In auto feed drilling machine all necessary safety equipments are installed and the process is designed by poka yoke techniques. Auto drilling machine manufactured by us are very heavy duty and sturdy in construction, perceived for its high performance and very low maintenance cost. Elements of power pack and electrical panel accessories used are of Standard make online with latest industrial standards. Auto feed Drill Machine are supplied complete with Electricals & Accessories of Standard make.

...more

drilling tapping machines

Be first to Rate

Rate ThisOpening Hours