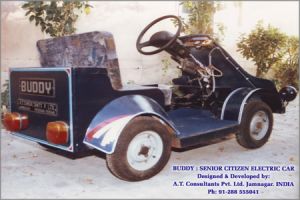

Senior Citizen Electrical Vehicle

Buddy – A Senior Citizen electric vehicle designed and developed by us:The concept of "Buddy" car - a single seater senior citizen vehicle was designed to offer mobility and independent commute to the elderly or disabled where the vehicle can be used for short distances around the city. Being a four wheeler, the concept of a car driving is held in the mindsets, eliminating the feel of being senior or specially challenged. This car was a prototype made in the Y2K times.As we all know Electric vehicles are gaining attention as an option for improving air quality and lessen the dependency on imported oil. While today’s technology is considered to be emerging as new, battery powered vehicles have been around since a long time. EV’s were in the market even before the gasoline automobiles and records show that some 50000 EV’s were used in the US sometime during 1912.EV’s are ZERO EMMISSION VEHICLES because they produce no pollution from the tailpipe or through fuel evaporation. This means that EV’s can greatly reduce emission of carbon monoxide and smog forming pollutants in the cities with dirty air.Promoting EV’s will be a considerable movement towards offering clean air and control the global warming hazard over the human life. Advantages of BUDDY: Buddy – is a single seater electric vehicle with space for little luggage or another companion to squeeze in if need be!Total maneuverability for a senior citizen.Designed as a four wheeler, it gives the feeling of a car; while overcoming the challenges of driving a big car in congested and traffic full areasIt is easy to take anywhere in the city as it is small in size.It is easy to drive on the roads as it mingles with the other traffic like the scooters and auto rickshaws on the street. Though the speed is limited to 25-30 kmph; the city traffic does not allow any vehicles to cross this speed limit anyway.It is easy to park.It is easy to plug it at night or in free hours in any outlets for charging the batteries.Open for a clear view – no doors; however safe as not just a two wheeled scooter!Good Road clearance.Very competitive in Cost! All in all: It is a great companion! Other uses:Pick up and drop offs for school childrenGrocery shoppingDriving in congested areas made easyDriving inside big factories or grounds also made easy.Inside airports for one passengerGood for amusement parksGood for children’s ride

...more

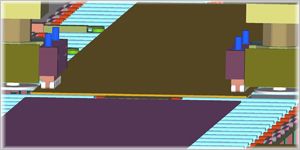

Plate edge Beveling Machine

This was a special purpose machine designed for beveling of both sides of a 60 mm thickness plate. There was a gantry designed with magnetic pick and place devices to load the plates on the machine. The plate would travel on the roller conveyors while the profile cutters would bevel the plate from both the sides while it travels through the table

...more

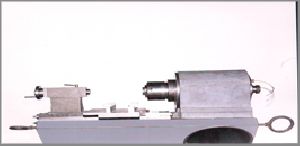

Pilger Machine

Special features of our pilgar mill with the latest technology available at an affordable price: 1.Full ring die with curved groove profile on die and mandrel to suit the smooth flow of cold pilgered material during cold forming whether it is s.s.,alloy steels or non-ferrous alloys e.g. Cu,Al etc.2.High productivity because of higher cross-sectional reduction/stroke of mother hollow combined with higher speed because of better balancing of inertia and torque forces.3.Use of electronics by employing high reflex servo motors for unique feed and turn device and for automatic and continuous operation (with two feed and turn carriages). This enables elimination of mechanical elements such as gearbox, cams, springs etc., that minimizes the maintenance and increases the machine availability.4.The mills give the best commercial option and return on investment since production capacity on one mill replaces the combined capacity on a number of mills of other cheaper options that may not have these features. This also results in lesser manpower, lesser built up shed area etc. minimizing fixed cost (spent on building with no returns) and running cost (because of lesser manpower,consumables,overheads etc.) thus resulting in much lower cost of production.5.Most importantly the quality of rolled tubes improves metallurgically and dimensionally (because of heavy wall thickness reduction). The product achieves very stable dimensional tolerances, good surface finish and roundness and is ideal for selling to OEM’s at competitive prices in the world today. Hence, these Pilger Mills are very cost-effective and givesbest value for money.

...more

pilger die

The main function of this machine is to grind the groove of pilgar dies which are used in the cold pilgar mills for producing pipes. The machine is so designed that the complete groove will be generated automatically on the die with the specially designed motorized spindle. The machine is designed to The machine is fully automatic with four Axes CNC high end controller which is the top of line controller in the market. This machine is solely designed and manufactured to improve the quality of pipes and tool life in cold pilgar mills. The appropriate use of the machine may reduce the problems faced on the shop floor like tool breakage, reconditioning etc and save costs. The machine can be custom made to handle any sizes of dies ranging from 100mm to 650 mm of diameter and the width of dies from 80 mm to 180 mm. the groove diameter can be from 10 mm to 90 mm. the dies can be reground to a different size after using it on to the mills. Special features of the machine includes motorized spindle, probe for inline measurement and advanced automization to contribute to time and cost savings. This machine has proven to be an import substitute for the Indian market as well as cost effective for the global market in every aspect of technological advancements, accuracies, tool room costs and quality of the pipes.

...more

NC Cold Saw Cutting Machine

Cold saw cutting machine is a special machine used in the tube manufacturing and the tube processing industry, in steel mills, forge shops, in steel producing mills wherever bars or shapes must be sawed in continuous line.This machine was developed for cutting steel bars, tubes in layers, bars in a length of up to 20 meters of square or round shapes. Specially designed carbide saw blades are used for providing high output through continuous operation even when cutting large batches and hard materials. There are hydraulically operated fixed vice jaws used ; both horizontally and vertically for clamping the tube diameters which ranges from 24 mm to 105 mm.Easy access to changing of blades is so designed that it can be changed in a simple and quick manner.The machine offers advantages like Quick cutting, Minimum burrs and clean metal surfaces without structural deformation, Tension and crack free cuts, Less material cost as result of minimum possible stock removal available, Cost saving technology for the industry.The machine can be customized for any size and material as per the specifications and requirement of the customers.

...more

insert grinding machine

This is a special purpose 12 Axes CNC insert grinding machine designed and manufactured to grind FPS inserts on all eight working sides; including both up and down sides. The loading and unloading of the inserts with a magazine is done automatically with pneumatics so designed to place the inserts for grinding with a special fork and then place it back on the tray table after grinding. The grinding of carbide inserts is done with specially designed two motorized grinding spindles. The CNC program designed for grinding offers a complete automatic cycle from auto loading, grinding, indexing and unloading of the inserts. The dressing is also programmed into the CNC for auto dressing cycles of diamond wheels. Machine consists of 12 Axes CNC high end controller, coolant filtration unit, spindle chiller unit, hydraulic power pack, mist collector etc The machine is centrally controlled by PLC giving individual commands to each unit to work independently.

...more

hybrid electric vehicles

Worldwide Environmental concerns have placed pressure on the development of low and zero emission vehicles. Legislations in different countries are bringing ever more stringent requirements on new vehicles. At the current time the zero emission requirements can only be met by batteries, with fuel cell technology still in development. The problem with the batteries is their low power density compared to fossil fuels. For this reason, the hybrid electric vehicle concepts have grown to meet the low and the ultra low emission requirements. Highlights and Distinguished features of the Hybrid system designed by A T Consultants. The Hybrid systems are designed either on parallel or on series systems. Our system is a series system.A specially designed High speed AC induction motor is used in the system. The motor is light in weight, compact in design, has high speed and torque and functions at 100 Hz. The frame size of 160 mm gives a continuous torque of 89 KW and a peak torque of 118 KW. The motor runs at a maximum speed of 10000 RPM and a minimum base speed of 3000 RPM. The stator and the rotors are such designed that the motor is a liquid cool motor. Such design gives excellent results and offers the distinctive feature in the system. Another unique concept is of the compressor designed for the Hybrid system. Normally, the braking of the vehicle works on pneumatic power. All compressors are connected to the camshaft of the engine and never goes beyond 1500 RPM so all the currently used compressors have 1500 RPM and are bulky and big in size. The compressor designed by us has 3000 RPM and the size to fit it is as compact as an Airconditioner fit into a car.

...more

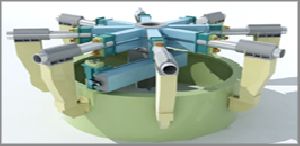

flange facing machine

This machine is a remote controlled portable In-Situ Flange facing and Boring machine used for facing the large FlangesShells at the ship breaking yards and oil industries. Any type of drilling, tapping, machining, boring etc operations are possible to do on this machine. This machine can be operated horizontally as well as vertically. It can be mounted to the flanges horizontally or vertically. A specially designed octagonal capsule has the clamping facility with interchangeability for internal diameter as well as different setting arrangements for external clamping on the same settings. The complete machine is held with eight rigid clamping to do the machining in both the settings. This machine can handle job sizes of Range 550 mm to 3000 mm. The entire operation is done with remote control. The machine can be customized for any sizes of Od and Id machining as per the requirement of the customers.

...more

electric pedicab

This is a pedal rickshaw cum a battery operated electric vehicle; mainly designed for city commute."KUKI" - the yellow tricycle puller was developed for those who are less fortunate in terms of income where they pull passengers in such rickshaws seen in the stqte of UP, and many pilgrim places. The person does this for making his living. He can ride upto 40 kms by himself, whereas the combination of the battery support provided here as an electric vehicle combined to rickshaw pulling can offer him double the kilometers, The battery supports up to 50-60 kmsin one charge of 6-7 hours, and the rest of the kilometers if at all he pulls would be another 40 kms which gives them double the earning and less physical trouble promoting good health and better life for these people. This was part of the CSR project of our company in Jamnagar Gujarat, initiated by ourDirector Mr P J Budhabhatti. Although these concepts are not commercialized, we wish to do so with partners who wish to venture into these ideas that will make a better tomorrow for the country and we wish to offer it to the custoers in the market also.Kuki can also be introduced in the congested areas of the market, or for shuttle service in the metro cities for metro rail stations, and at places where approach of vehicles are prohibited; like national monuments and small streets.To give an idea on the pricing, each of these "KUKI" type EV's if in large scale production may run anywhere from 75-80K.

...more

Pipe Beveling Machine

This machine is designed for beveling of the pipes of large size in length up to 4 meters and diameter of 2.5 meters. Since the pipes are generally not round and the thickness is less, the tool for machining must be guided by the pipe itself so that the face of the pipe can be beveled perfectly. The chuck is fitted with the specially designed tool – named – ‘dancing tool’ whcihholds the pipe through rollers inside and outside to get perfect beveling. The machine was conceptualized for one of our international clientele.

...more

CNC Yoke Machine

This machine is a automatic PLC controlled Steering Yoke manufacturing machine. The yoke of the steering wheel is loaded at one station and it travels through nine different stations to do seven different operations on the piece. Since there are nine stations in a rotary table, all the operations are done simultaneously on each station while the table moves with the rotation on single station holding one job for a particular operation. This saves time and increases the productivity. Stations included job loading, facing of all sides, drilling of holes, boring, spot facing, tapping, slitting, chamfering and unloading of the jobs on an in line bin.This machine was specially designed for offering accurate jobs with minimum time and therefore savings of costs and labor. The single machine alone replaced small turning machines and lathes occupied for each operation.The machine was highly productive and gave results from raw to finish product for the parts sold in the automobile industry.

...more

CNC Tool Room Education Lathe Machine

ATG-50-CNC is an education cum tool room lathe. This CNC controlled lathe offers the turning operations of jobs with expedient facilities and offers institutional training for advanced education. It coincides with the standards of modern technology with its unique concept while maintaining in all the operational and functional requirements of a CNC lathe machine.Ideal for education institutes, it can offer small and medium scale job workers a highly productive and cost effective solution for their business. Speed, accuracy, easy maintenance, programmable operations for repetitive and reliable job accuracies, touch screen controls, AC spindle drives and PC interface are amongst the few advantages this machine can offer to its customers.Facilities of G codes, M codes, Graphics and Zoom facilities, Customized Macro programs, Simple part programs for jobs of length up to 200 mm and diameter up to 100 mm and facing of plate up to 300 mm;; the machine offers flexibility to the customer. Built in spindle The machine uses very little floor space and yet offers large benefits to the customer with the features designed for optimum use. International market would find a very cost effective solution with this machine.

...more

CNC Roll Groove Turning Machine

This is a specially designed CNC Roll Groove Turning machine used for turning of the three rolls fitted to the SRM – Stretch Reducing Millstands used in the PQF mills. The rolls are machined in an in situ condition on the stands meaning that the rolls are not taken out of the stands for machining but all the three rolls are machined in the assembled condition in the stand under the required accuracies. The concentricity of all the three grooves, root diameter of the rollers, centering of the stand etc is taken into consideration for the accuracies of the stand to produce a perfect pipe on the PQF mill. The stands are used in order to maintain the sizing, finishing and to control the geometrical tolerances of the pipes. The machine is used to redress the worn out surfaces of the rollers in the SRM stands to achieve the required accuracies on the pipes. Once the rolls are machined, the same stands can be used in the PQF mills for producing the required pipes. Therefore it is also called a Callibration machine. Special cycles are developed for machining these rolls on the stands. The cycle uses interpolation of the axes to get the machining done. Specially designed probe cycle us also used to assess the pre and the post machining parameters. A combination of mathematical formulas, intense mathematical calculations and features of a high end CNC comtroller used to program the cycles has been successfully designed to meet the requirement of this application. The result of using this machine for calibrating the stands is extraordinary in terms of accuracy on the end product – the pipes, and in terms of the time taken in getting the job done which is highly productive and in turn profitable to the company. Similar machine is developed for mills using round stands also. The machine is fully automatic and is customized for the specific sizes of the roll stands of width 250 mm and 390 mm and length of 660 mm and 1100 mm respectively with the roll diameter of 275 mm and 450 mm respectively. A loading and un-loading system is also specially designed for the machine to suit the customer requirement. The machine was an import substitute and can prove to be very cost effective for the international market also in terms of capital costs, time and productivity. Specially designed in line degreasing system was introduced for the first time in one of these machine which cleans the OD and ID of the billets with hot water, alkaline solution and hot air before placing them on to the unloading table. This was conceptualized for one of our customers using this machine. The system was accurate and cost effective for the customer.

...more

CNC Pilger Die Groove Grinding Machine

This is a special purpose CNC Die Groove Grinding machine used for dies used in the Pilgar mills. This machine is a tool room machine for the pilgar mill machine owners.The main function of this machine is to grind the groove of pilgar dies which are used in the cold pilgar mills for producing pipes. The machine is so designed that the complete groove will be generated automatically on the die with the specially designed motorized spindle. The machine is designed to The machine is fully automatic with four Axes CNC high end controller which is the top of line controller in the market.This machine is solely designed and manufactured to improve the quality of pipes and tool life in cold pilgar mills. The appropriate use of the machine may reduce the problems faced on the shop floor like tool breakage, reconditioning etc and save costs.The machine can be custom made to handle any sizes of dies ranging from 100mm to 650 mm of diameter and the width of dies from 80 mm to 180 mm. the groove diameter can be from 10 mm to 90 mm. the dies can be reground to a different size after using it on to the mills. Special features of the machine includes motorized spindle, probe for inline measurement and advanced automization to contribute to time and cost savings. This machine has proven to be an import substitute for the Indian market as well as cost effective for the global market in every aspect of technological advancements, accuracies, tool room costs and quality of the pipes.

...more

Cnc Mandrel Grinding Machine

Mandrel is the basic tool required in Cold Pilger Mills or Cold Tube Rolling Mills in tube industries. The inner dia of the tube or pipes are controlled with the mandrels i.e. size and finish of the tubes / pipes are controlled with the mandrels. To control the inner diameter of tube is very essential. To achieve the good quality of the tubes the die and the mandrels should be properly ground and it should meet the close tolerances with each other. Also the surface finish of the tubes is very much dependent on the surface finish of mandrels. Basically mandrels are in form of taper shaped shafts. As per the tool designer for tubes on the pilger mill, the data is generated for forming of the mandrel. The general arrangement of the mandrel grinding machine is like cylindrical grinder. But, the cylindrical grinder has its limitations for grinding. Mandrel grinding machine is designed and manufactured as per the requirement to make the perfect tool for pilger mills. Machine is capable to grind each and every point on the mandrel as per the data generated by the tool designer. Mandrel grinding machine consists of 4 axes. After completion of the processes on the mandrel like rough turning, hardening etc, mandrel is to be placed and fitted in between center to center in the machine for grinding. Machine will grind as per the tool data. And auto CNC program will perform the grinding operation. Dressing of the abrasive wheel will be done automatically through CNC program after specified durations. After grinding the mandrel, the mandrel is checked with the probe after checking as per the required The machine grinds the mandrels of size 105 mm in diameter and 1200 mm in length. The machine is custom made as per the requirement of the customer and is part of the tool room equipment for all pilgar mill owners in the industry.

...more

CNC Billet Radiusing Machine

This machine is specially designed for the tube industries.The machine consists of the main machine, auto loading and unloading units for the billets. It is a fully automatic CNC machine. When a billet is on the loading table, the arms of the loading table loads the billet from the table, machines it, and unloads it to the unloading table all of which is done automatically. The machine is capable to radius the billets ranging from 143 mm to 250 mm diameter of billets and 350 mm to 900 mm length of billets.The billet radiusing machine is used for radiusing and chamfering the ends of billets used in the extrusion press for extruding the tubes used in the tube industry.The billets are end faced so that the flow of the material when extruded will be uniformed.The machine can be customized to suit the customer requirement for any sizes and material. Specially designed in line degreasing system was introduced for the first time in one of these machine which cleans the OD and ID of the billets with hot water, alkaline solution and hot air before placing them on to the unloading table. This was conceptualized for one of our customers using this machine. The system was accurate and cost effective for the customer.

...more

CN Insitu Flange Faching Machine

Generally any job required to be machined goes to the machine for its operation. When jobs like very big shells and flanges are to be machined it cannot be brought to the machine and special designed machines are to be manufactured to hold the machining at site to go there and do the machining. This machine is a remote controlled portable In-Situ Flange facing and Boring machine used for facing the large Flanges/Shells at the ship breaking yards and oil industries. Any type of drilling, tapping, machining, boring etc operations are possible to do on this machine. This machine can be operated horizontally as well as vertically. It can be mounted to the flanges horizontally or vertically. A specially designed octagonal capsule has the clamping facility with interchangeability for internal diameter as well as different setting arrangements for external clamping on the same settings. The complete machine is held with eight rigid clamping to do the machining in both the settings. This machine can handle job sizes of Range 550 mm to 3000 mm. The entire operation is done with remote control. The machine can be customized for any sizes of Od and Id machining as per the requirement of the customers.

...more

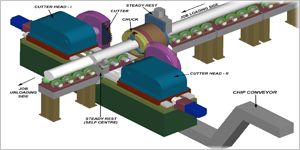

Bar Cutting Machine

The design is conceptualized on the requirement of bar cutting of SS material for Bar sizes of 350 mm in diameter to be cut in practically half the time then normal time taken to cut it in full. The cutting is dry cutting standard circular saw. Very high speed and high capacity spindle motors are used for the operation. Two cutters would approach the bar simultaneously for cutting up to nearing the center of the bar, and thereafter the bar would rotate to complete the cutting. The machine is highly efficient for productivity and fully automatic to offer accurate bar cuttings for the steel industry. It can be custom made to handle any type of bar size and length.

...moreBe first to Rate

Rate ThisOpening Hours