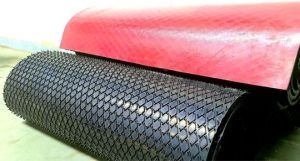

Diamond Groove Lagging Rubber Sheets

Get Price Quote

100 Roll (MOQ)

Waidhan group manufactures a comprehensive range of diamond and plain rubber lagging sheets for general, industrial and mining applications. We manufacture both small and large diamond profile pulley lagging. Diamond grooved lagging sheets are ideal for driven pulleys with high tensions and belt ratings. They are press cured using high temperature and pressure thus proving to give significantly longer life.

Rubber Pulley Lagging

Get Price Quote

Our organization has all the essential logistic resources and links to ensure on schedule delivery of order(s). Maintaining high standards of our extensive array of products, we focus on the quality of raw inputs and material used at the initial stages. With this, the final product comes out to be the finest.

Best Deals from Rubber Lagging Sheet

Pulley Lagging Rubber Sheet

Get Price Quote

5000 Meter (MOQ)

Pulley Lagging Rubber Sheet

720 - 2,400 Per Meter

50 Meter (MOQ)

Rubber Lagging Sheets

Get Price Quote

We are leading manufacturers & exporters of all type of premium quality Rubber Lagging sheets for Conveyor Pulleys. Our Rubber Lagging Sheets are available in various sizes and specifications that can be customized to meet specific requirements of the clients. 1. Diamond Grooved : Our Rubber Lagging Sheet eliminates belt slippage, increases belt life, its open design dissipates dirt, water and material build-up. Diamond Pattern Lagging: Ideal for all type of diameter pulleys on systems with conveyor belt. It prevents belt from slippage (in particular when water is present) and increase the drive traction of the pulley. It also deflects water into lateral or diamond shaped grooves, away from pulleys. Diamond Grooved Pattern: diamond grooved /pulley lagging rubber sheet provide protection from wear and corrosion and reduce material build-up. view more

Pulley Lagging Rubber Sheet

Get Price Quote

We hold expertise in supplying precision engineered Pulley Lagging Rubber Sheet. Our Pulley Lagging Rubber Sheet is available in different sizes, shapes and specifications. It is used in households, packaging industries etc. Further, Pulley Lagging Rubber Sheet is widely applauded by the customers for its excellent quality, flawless finish and high durability.

Diamond Groove Pulley Lagging Rubber Sheets

2,500 - 3,000 Per Square meet

Pulley Rubber Lagging

Get Price Quote

Diamond pulley lagging Rubber sheet

160 Per Kilogram

We are supplier of diamond pulley lagging rubber sheet. Its use in conveyor pulley .its very good quality of rubber.

Diamond pulley lagging Rubber sheet

Get Price Quote

1 Piece (MOQ)

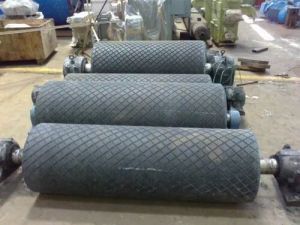

DIAMOND PULLEY LAGGING TROUGHED PULLEY CONVEYORS PULLEY LAGGING INTRODUCTION Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells. Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged for exactly this reason. This section provides some useful information regarding the different types of lagging as well as some technical details and recommendations for lagging of pulleys. DIAMOND PULLEY LEGGING Rubber lagging is applied to pulley shells in order to improve the friction between the pulley and the belt. Conveyor drive pulleys are often supplied with diamond grooved lagging as indicated in the adjacent sketch. ‘Diamond grooved lagging’ refers to the pattern in the lagging and this pattern, like with vehicle tyres, enhances the grip or friction even if the belt surface is dirty.

rubber lagging sheet

Get Price Quote

We are leading manufacturers & exporters of all type of premium quality Rubber Lagging sheets for Conveyor Pulleys.Our Rubber Lagging Sheets are available in various sizes and specifications that can be customized to meet specific requirements of the clients.Diamond Grooved : Our Rubber Lagging Sheet eliminates belt slippage, increases belt life, its open design dissipates dirt, water and material build-up. Diamond Pattern Lagging: Ideal for all type of diameter pulleys on systems with conveyor belt. It prevents belt from slippage (in particular when water is present) and increase the drive traction of the pulley. It also deflects water into lateral or diamond shaped grooves, away from pulleys. Diamond Grooved Pattern: diamond grooved /pulley lagging rubber sheet provide protection from wear and corrosion and reduce material build-up. We are manufacturing and supplying, our Lagging sheets in various Cover Grades with different Profiles like Grade Covers Abrasion Resistant HR / SHR Grade FR Grade White / Hygienic, Food Grade Big Diamond, Mini Diamond Small Diamond Square Diamond (Best profile with high flexibility, which can be easily used from both directions, which helps in reducing wastage). Plain Rubber Lagging Hearing Bone / Wavy Top Lagging Strip Lagging : Strip lagging is an cost effective, convenient, more durable & flexible, air bubble resistant pulley lagging process. There is almost no/ minimal wastage of ‘INSTA STRIP’ rubber lagging sheet material. It is available in standard / manageable/ maneuverable size of 200 mm / 400 mm width and continuous length of 50 / 100 meters or tailor made as per customer requirements (still larger diameter rolls are available subject to transportable diameter/ weight). ‘INSTA STRIP’ is light weight , handy and easy to install.‘INSTA STRIP’ strip lagging being manageable / maneuverable is easy to install , removal of entrapped air is possible, requiring less down time.‘INSTA STRIP’ strip lagging sheet is available with SPECIAL BONDER RUBBER. This feature facilitates strip lagging application directly to the pulley (no buffing/ grinding of ‘Insta Strip’ is required) and offers very high bond strength between pulley and the strip lagging.We are manufacturing and supplying, our Lagging sheets in various Cover Grades like in Big diamond / Small diamond Abrasion Resistant FR Grade HR / SHR Grade White / Hygienic, Food Grade RUBBER SKIRTING Available in Thickness: 5 mm to 40 mm. Available for Special Application: Heat Resistant Grade, Fire Retardant, Hygienic. Conveyor belt skirting rubber is used extensively for sealing on plant and equipment used for processing and material handling. Skirting rubber is primarily designed for use as a sealing strip around conveyor system loading, transfer and discharge points to direct material onto the conveyor belt and reduces spillage. It is also suitable for use in any application which requires a flexible and durable sealing material. Skirting rubber is available in full width slabs or pre-cut skirting rubber strips to suit standard conveyor system designs. Custom width & thickness of Rubber Skirting strips can also be supplied as per customer requirements. Continental Conveyors (P) Limited has the technical expertise to advise the best skirting rubber solution based on specific application requirements.Rubber Skirt Blocks : Continental Conveyors (P) Limited, Skirt sealing system is designed to seal the skirt at the loading station of the conveyor. The segmented rubber blocks guided by the guide plate on one face and supported by serrated clamps plates on the other face ensure effective sealing to match belt profile.VULCANIZING SOLUTION : The ‘CCPL-INSTACON’ R & D team has designed and developed “INSTA FIX” a high peel strength, reliable, instant ready to use jointing/ vulcanizing solution for belt jointing, belt repairing, pulley lagging fixing etc.Benefits of ‘INSTA FIX’ The belt joint, repaired portion can be put to use instantaneously, it is readily available, easy to handle and store. High peel strength. ‘Insta fix’ can be used for jointing, repairing, lagging etc. The chances and fear of jointing area contamination is eliminated as the jointing is instant and no drying or waiting is required. It does not require special procedures. Require normal storage conditions. We are more than positive that after going through the merits of ‘INSTA FIX’ you would like to go for a trial to avail all the benefits offered by ‘INSTA FIX’ to the best of your organizations gain e.g. reliable, instant, easy, clean, jointing/ repairing of the conveyor belts thereby saving precious time and money. On our part, through our other quality products and services, we assure reliable, easy and cost effective material conveying at all times. VULCON INSTAFIX (Available for Heat Resistant & FR Grade Belts.) ‘Insta fix’ can be used for jointing, repairing, lagging etc. Hot Vulcanizing Kits Skim Compound & Cover Compound RUBBER GOURMET / BEADING : Our Rubber Beading / Gourmet are in compliance with industrial standards, which are manufactured with best quality rubber. Our “CCPL-INSTACON” make Rubber Beading which are Water Proof have Super-fine finishing and high durability. We can manufacture & supply as per standard design & as per customer’s requirement.IMPACT RUBBER RINGS : Can be manufactured in various sizes for Critical & Super-Critical Applications with maintained Hardness as per Application with Anti-Abrasive Properties.Impact Rubber Rings are used for Material Conveying Machineries / Equipments.We manufacture & export high quality Impact Rings, deliver ultimate performance with superior flexibility.RUBBER SCRAPPER : We have been manufacturing & exporting Rubber Scrappers, which are used in material handling systems, to keep the Conveyor belts clean and to avoid rollback of material and spillage. Our Rubber Scrappers are very cost effective measure to, keep industrial belts clean. Our Scrappers helps in reducing maintenance and lower the downtime, and can be used in Critical & Super-Critical applications. We manufacture various types of Rubber Scrappers for Internal as well as External cleaning of rubber Conveyor Belts.

Pulley Lagging Rubber Sheet

1,800 Per Meter

100 Meter (MOQ)

Pulley Lagging Rubber Sheets

1,000 - 3,000 Per Meter

100 piece (MOQ)

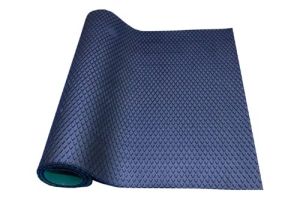

Clients can avail a quality range of Pulley Lagging Rubber Sheets from us. These Pulley Lagging Rubber Sheets are known for improving the friction coefficient between conveyor belt and driven pulley, and thus are used for covering the pulleys under the rubber conveyor belt. These Pulley Lagging Rubber Sheets have diamond grooved design on top surface, and another surface is anti-skid that eases the installation. We use mixture of natural and synthetic rubber for the manufacturing of these Pulley Lagging Rubber Sheets. These sheets are used in various industries for bulk handling, and are resistant to adverse weather, temperature, and radiation etc. Features : Pulley Lagging Rubber Sheets are resistant to heat, oil, temperature, whether, ageing and are abrasion resistant for long term service. Application : Used in almost every industry for bulk handling. Size Length x Width : 1meter x 2 meters, or as per customer’s requirement. Thickness 8mm 10mm 12mm 15mm Surface : Smooth on both sides (plain rubber sheets) Diamond groove on one side & fabric-impression/smooth on other side. Skirt board rubber strips or sheets are also a part conveyor belt system; it is placed at both sides of conveyor belt to prevent the fall of material carried on conveyor belt. We manufacture skirt rubber sheets in a wide range of width, length & thickness.

rubber lagging sheet

Get Price Quote

We in consistence technically design manufacture and export huge quantity of Diamond Groove Grip Rubber Sheets with bare bottom according to our buyers users requirements in Diamond Rubber Grooves with Heights of 10mm, 12mm and 14mm. These Rubber Sheets are available in various types and designs with specifications:

Rubber Pulley Lagging

4,500 Per Piece

100 Piece(s) (MOQ)

Pulley lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and take-up. key benefits: Extends the life of key conveyor components. Reduces wear from abrasive materials. Prevents belt slippage by increasing the coefficient of friction between the conveyor belt and the pulley. Creates a self-cleaning action on the pulley surface and prevents the buildup of transported bulk material, water, snow or ice.

Pulley Lagging Rubber Sheet

1,450 Per Square Meter

Rubber Pulley Lagging

10,000 - 1,200,000 Per Piece

10 Piece(s) (MOQ)

Ceramic Lagging Rubber Sheet

10,000 - 11,000 Per Square Meter

25 Square Meter (MOQ)

Pulley Lagging Rubber Sheet

Get Price Quote

Pulley Lagging Rubber Sheet prevents belt slippage and protects from wear and corrosion and reduces material build-up. They also infuence belt tracking positively. They are available with plain, diamond or square profiles, with or without special bonding layer.They are manufactured from high-grade natural and synthetic rubber specially designed to deisplay excellent abrasion and ozone resistance. They are widely used in various industries for bulk handling and are resistant to adverse weather, temperature and radiation etc. It is vailable in a wide range of hardness from 40° to 70° Shore A and working temperature range of -30°C to +70°C.

Pulley Lagging Rubber Sheets

Get Price Quote

We are mfg. and distributors of positive drive pulley(Timing Pulley) . Timing Pulleys are manufactured from quality materials Ferrous and non-Ferrous and or as per customer's drawing. We exports rubber products like rubber sheets.Mainly we are involving with FORWEAR, FORCHEM, FORSKIRT, FORSYN.

Zenith Pulley Lagging Rubber Sheets

Get Price Quote

10 Kilogram (MOQ)

We offer zenith pulley lagging rubber sheets. Available with withwithout neoprene bonding in - small square large diamond designs

Geogrip Brand Lagging Rubber Sheet

Get Price Quote

Specially made for conveyor pulley rubber lagging, tank lining etc… Extra bonding power and high abrasion resistant. Available in standard profiles, plain, diamond grooved, square grooved, ceramic embedded etc.. It has sticking element at bottom for extra bonding. Various thicknesses available,2mm & above. No curing time required.

Pulley Lagging Rubber Sheet

Get Price Quote

We are offering pulley lagging rubber sheet., we can sypply as per customer requiements width upto 2000mm.

Rubber Lagging Sheets

Get Price Quote

We offer Rubber Lagging such as Rubber Lagging Sheets, Rubber Lagging for Pulley and Rubber Lagging for rollers to the customers in the domestic market. We use mixture of natural and synthetic rubber for the manufacturing of our Rubber Lagging Sheets. They have high functional life due to its resistant to adverse weather, temperature, radiation, abrasion etc. Customers can avail our Rubber Lagging Sheets as per their specifications at market leading prices.

rubber lagging sheet

Get Price Quote

Improved coefficient of friction means less tension required. Reduces material build up. Significantly reduced occurrence of belt slippage in wet conditions. Increased protection of pulley shell from wear leading to early failure. Can be applied in-situ. Jaw Crusher Parts AVAILABLE SIZES Sr.No. Description Inquiry 01 Rubber Lagging Sheet 8 stalco 02 Rubber Lagging Sheet 10 stalco 03 Rubber Lagging Sheet 12 stalco 04 Rubber Lagging Sheet 14 stalco

Pulley Lagging Rubber Sheet

550 Per Square Feet

Conveyor Pulley Lagging Rubber Sheet

6,000 Per Square Meter

100 Square Meter (MOQ)

rubber lagging sheet

Get Price Quote

Conveyor belt pulley lagging sheet manufactured of quality synthetic rubber neoprene or SBR rubber diamond grooved or plain finish made in India by HIC Universal superseding ISO 1629, DIN 53516, DIN 53479 quality standards. Pulley lagging sheet manufactured Width and Length sizes 1 m x 2 m and 1.2 m x 2.4 m, Thickness MM 6.5, 8, 10, 12, 15, Finish Diamond or Plain, plain up to max 10 meter long, Wear factor 80 mm3 at 10N, T.S. 7~15 MPa, Elongation Min 300%, Color Black, Rubber grade Natural or FRAS or White Nitrile Food, Shore Hardness A 60 ± 5, 70 ± 5.

rubber lagging sheet

Get Price Quote

Gutter less design for cleaner compatibility reduces belt vibration and cleaner chatter for standard application with minimal slippage.Pulley lagging rubber sheets are used to eliminate belt slippage, increase pulley life, improve water shedding

rubber lagging sheet

Get Price Quote

CORI manufactures a comprehensive range of rubber Sheets are available in various size and thickness to withstand a temperature range between -40°C and +250°C conforming to international standards and customer requirements. sheets for general, industrial and mining applications. It includes vulcanised black and coloured sheets for technical uses and industrial application with or without textile insertion, with smooth surfaces or with a canvas-type print on one or both sides.