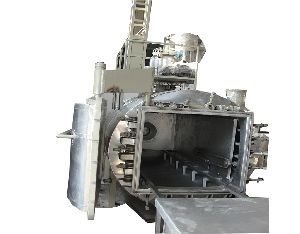

DM-60 Drum Mixing Plant

Get Price Quote

We deliver DM-60 Drum Mixing Plant, which is built with precise engineering and is acclaimed for its sturdy make and long service life. We keep our warehouse clean and installed it with advanced machines due to which the entire lot remains free from different types of damages such as moisture, dust, rain and others. We have ultra-modern packaging systems available to keep the products safe from physical factors that may damage the product to some extent. Thus, we only use qualitative packaging material.

Mild Steel Tile Adhesive Mixing Plant

150,000 Per Unit

1 Unit (MOQ)

Best Deals from Mixing Plant

Phenyl Mixing Machine

1,999 Per Piece

1 Piece (MOQ)

Compact Concrete Batching Mixing Plant

Get Price Quote

1 piece (MOQ)

Asphalt Drum Mixing Plant

2,000,000 - 3,500,000 Per Piece

1 Piece (MOQ)

Ready Mixed Concrete Mixing Plant

1,700,000 Per Piece

Epoxy Mixing Cum Casting Plant

90,000 Per Piece

1 Piece (MOQ)

Continuous Asphalt Mixing Plant

Get Price Quote

The Drying and Mixing unit of the asphalt plant demands complex flight design and heat transfer technology. With continuous R&D and incorporation of the latest design up-gradations; Our thermodrum is miles ahead of competition. The thermodrum unit follows a triple heat transfer system by conduction, convection & radiation technologies ensuring transfer of heat to the aggregates, translating into higher productivity and lower fuel consumption. The unique flight design ensures total heat transfer, a thorough mixing & coating, lower emissions and prevention of bitumen oxidation.

Epoxy Mixing & Casting Plants

Get Price Quote

In order to obtain void-free epoxy castings with low partial discharge and good du-electric strength suitable for use at high voltage it is necessary, among other things, to mix the resin & pre-dried filler well, to de-aerate it by vacuum and finally to pour it, also in vacuum. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Water-cooled trap is provided for preventing volatile hardeners from entering the vacuum pump. Pouring chamber can be heated or unheated as required. Rotary turntable with vacuum-tight rotary seal or chain & sprocket driven trolley or rails allows the moulds to be positioned below the pouring spout without breaking vacuum. Epoxy mixing & de-aerating plant: Medium size epoxy vacuum mixing plant for use in the laboratories of a progressive Electrical Manufacturer can handle from 5 kg to 200 kg of Resin-filler gardner mix. It is very versatile being able to handle solid or liquid resins hot or cold processing. Temperatures fro 160oC to room temperature are possible. A vacuum of 1 torr is easily obtained. the use of the plant enables void-free castings to be obtained. Our Team The reason behind the success and growth of our organization is the support of our competent team of experts. These professionals have industry expertise of many years and posses a thorough knowledge in their respective domains. We make sure that the professionals are regularly trained to keep them updated about the market scenario. The team consists of the following: Technicians Quality controllers Research & development associates Sales & marketing executives With the united and tenacious efforts of these professionals, we ensure that the products offered by us are in compliance with the needs of our clients.

Direct Feeding Concrete Pump Mobile Mixing Plant (GEPL CBC - 30)

Get Price Quote

With an increased GEPL CBC 30 model, our Direct Feeding Concrete Pump Mobile Mixing Plants are one of our most bestselling Mixing Plants due to their long service life, high efficiency and low maintenance costs. Tested against international standards and regulations, these Direct Feeding Concrete Pump Mobile Mixing Plant (GEPL CBC - 30) have been created keeping the customer’s needs and wants in mind. Our cutting-edge technology and techniques guarantee that this product will be the best deal in the market.

mobile concrete batching mixing plant

Get Price Quote

In Built Skip and Feeder Plant is highly acclaimed on running sites. Three Bin Feeder each for sand , 10 mm & 20 mm can be easily filled with the help of loader or excavator. After Weighing of Aggregate material is being poured in the Mixing Unit with the Skip Sliding up and down in definite track path. This plant can be easily transfer within site with the help of a tractor. Easy to operate and easy to maintain. Cement pouring is done with the help of screw conveyor. Separate Provision for Water and Ad-Mixture.

Modular Concrete Mixing Plant

4,700,000 Per unit

Epoxy Mixing Cum Casting Plant

Get Price Quote

Overview Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a thermosetting polymer. During the setting process, the liquid monomer polymerizes into the polymer, thereby hardening into a solid. Our resin casting plant is manufactured using quality components and spare parts to ensure optimum performance and long functional life. Resin casting plant is integrated with mixing chamber, which is designed with heating system with temperature controlling arrangement. The simplest method is gravity casting where the resin is poured into the mold and pulled down into all the parts by gravity inside a vacuum chamber. The casting is done in a vacuum chamber to extract the air which avoids formation of air bubbles. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Features : Mixing chamber for mixing of resin, with hardener, accelerators, pigment and filters, of capacities from 5kg to 1000kg, designed for high vacuum degassing. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required. Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum. Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves. The plants can be offered continuous production process. Applications : CT and PT manufacturer Dry type transformer etc

Double Drum Asphalt Mixing Plant

3,500,000 Per Set

1 Set(s) (MOQ)

Our double drum hot mix plant is suitable for high capacity mixing requirements, in out double drum asphalt mixing plant the drying of aggregates and mixing of aggregates is done in two different drums given precise mixing quality with anti gradation of aggregates and mix recipe.

Drum Mixing Plant

Get Price Quote

Concat RD-Series Concrete Mixing Plant

Get Price Quote

Concat - RD Series is dedicated to Concrete Batching & Mixing Plant with Reversible Drum Technology with Boom Scraper. This plant is available in two models ( RD-20 & RD -30)

Reversible Concrete Mixing Plant

Get Price Quote

Reversible drum mixer machines are designed to find out midway solution between concrete mixing machine and batching plants. Reversible drum mixer is an integration of two i.e. Drum mixer and batching plant.

Resin Mixing And Pouring Plant

Get Price Quote

Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a plastic thermosetting polymer. During the setting process, the liquid monomer polymerises into the polymer, thereby hardening into a solid.

akona rd series concrete batching mixing plant

Get Price Quote

akona rd series concrete batching & mixing plant is designed to meet practical requirement and it provides more flexibility for working. Fully automatic akona rd series concrete batching & mixing plants are available in following two different models with us namely rd-20 (20m3hr) and rd – 30 (30m3hr). Rd – 30 (30m3hr) rd series has separated digital weight display for all constituents. technical features : to1 : plc operated completely automatic control panel to2 : blade mixing technology with planetary gear-boxesto3 : electronic weighing system for better accuracy in design mix.to4 : separate weighing system for cement and fly-ashto5 : italian screw feeder, to pour cement speedilyto6 : password locking facility to7 : water and ad-mix pour by weightto8 : boom scrapper to make you work easierto9 : pneumatically operated gate for aggregate & sand to10 : italian vibratorsto11 : tabulated print our system for each batchto12 : no pit required only nominal civil workto13 : heat proof control cabinto14 : cement with vertical screw feeder (optional)to15 : e-mail & sms facility (optional)

Asphalt Drum Mixing Plant

3,150,000 - 5,350,000 Per Unit

1 Set (MOQ)

Asphalt Drum Mixing Plant