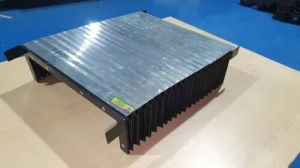

CTPT Transformer Bellows

2,000 Per Piece

1 Piece (MOQ)

Metallic Bellows

Get Price Quote

We, manufacture ss bellows from id 20 mm to id 2500 mm. We follow latest ejma standards and asme code for the design,manufacture & quality assurance of metallic bellows and joints. We manufacture ss bellows in all grades of 300 series steel and with all types of end fittings. We manufacture bellows suitable for various application in sector such as cement, fertilizer, chemicals,sugar,steel & iron, refineries,dg sets, power plants, petrochemicals, textile, automobiles, defence, nuclear, oil & gas, railways, shipping, heavy industries, instrumentation, cryogenic etc. We are also exporting wide range of ss bellows. Features abrasion resistance longer service life competetive pricing

Best Deals from Metal Bellows

Metal Bellows

500 - 50,000 Per Piece

Metal Bellows

10,000 Per Piece

1 Piece (MOQ)

Metal bellows products are used in a wide variety of industrial and mechanical applications and are designed to compress, extend, or bend to absorb axial and angular movement.

Metallic Bellows

Get Price Quote

The product range covers 1" to 6 mtrs I.D bellow square and rectangular bellows.Bigger sizes can also be made to customers requirements as the technology upgradation is the continues process at gandhi engineering company. We offer Pressure range from high vacuum to 70 kg/cm2 with various end connections and material of construction. SS 321/304/316/304L/Inconel/Monel/Non-ferrous metal etc. Bellows in Rubber/PTFE & fabric are also offered against specific demands.

Metallic Expansion Bellows

5,000 Per Piece

Metallic Expansion Bellows

Get Price Quote

Metallic Expansion Joints are installed in pipe work and duct systems to prevent damage caused by thermal growth, vibration, pressure thrust and other mechanical forces.There is a wide range of metallic bellows designs in a variety of materials. Options range from the simplest convoluted bellows used in petroleum refineries.Materials include all types of stainless steels and high grade nickel alloy steels. Any pipe connecting two points is subjected to numerous types of action which result in stresses on the pipe. Some of the causes of these stresses are: internal or external pressure at working temperature weight of the pipe it self and the parts supported on it movement imposed on pipe sections by external restraints thermal expansion Size Range :- 50 NB to 500 NB

Corrugated Metallic Bellows Without Braid

Get Price Quote

Our company is concerned within the manufacture of a good vary of SS furrowed golden Bellows while not Braid that is high on demand within the marketplace for a range of functions in numerous industries to be used as a spare within the construction method. These merchandise area unit offered to the purchasers at terribly cheap rates within the market and that we build use of the most effective machinery and technology offered within the marketplace for the manufacture of those merchandise.

non metallic bellows

1,350 Per Piece

We have a large infrastructure facility, parted into different segments and one of them is warehouse wherein we maintain a large stock for meeting bulk requirements of the clients. We are instrumental in offering extensive range of products that is in compliance with the internationally accepted standards. Thus, the final products are of excetional quality.

Metallic Bellow

Get Price Quote

We are manufacturer, exporter, designer & oem supplier of metallic bellow made of stainless steel 304, 302, 316, 321 etc. manufacturing capacity : rectangular - i.d. Upto 5 x 4 mtrs. square - i.d. Upto 4 x 4 mtrs. circular / round - i.d. Upto 3 mtrs. working temperature - upto 800â° c. working pressure - upto 10 kg. / cmâ². flow media - any type. application : steel plants, cement plants, boiler plants, thermal power plants, petro-chemical refineries, hvac, environmental systems, chimneys, water pipelines etc.

Metal Bellows

Get Price Quote

Metal expansion joints (MEJ) also called compensators or metal / metallic bellow. An expansion joint/bellow element employed in a piping system is an assembly of generally more than one convolute in series with the shape of the convolution designed to withstand the internal pressures, Thermal expansion, mechanical vibrations of pumps, draft fans, compressors, turbines, motors, vessels and other plant components, but flexible enough to accept axial, lateral, and angular deflections. They consist of one or more metal bellows. Metal expansion joints have to be designed according to rules laid out by EJMA (expansion joint manufacturing association).For Fabric & Rubber expansion joints there are guidelines and a state-of-the-art description by FSA (fluid sealing association). Expansion joints are differentiated according to the three basic types of movement: axial, angular and lateral expansion joints. The central component of each expansion joint is the metal bellows .Due to its shape and thin wall, acts like a spring. The bellows however has to meet the following basic criteria to qualify for its use as an expansion element. It must : • Withstand the operating and test conditions (pressure, temperature). • Ensure corrosion resistance. • Provide sufficient flexibility for the purpose. • Include sufficient squirm stability. MOVEMENTS & SPRING RATES: There are four basic movements that can be applied to a bellows. These are Axial, Lateral, Angular and Tensional. Respective spring rates are - Axial spring rate, Lateral spring rate, Angular spring rate. The spring rate of a bellows is entirely dependent on bellows geometry and material properties. AXIAL MOVEMENT (+/‐ MM): Axial movement is the change in dimensional length of the bellows from its free length in a direction parallel to its longitudinal axis. Compression is always expressed as negative (‐) and extension as positive (+). The units for axial spring rates displayed in N/mm. LATERAL MOVEMENT (+/‐ MM): This relative displacement of the two ends of an Expansion Joint perpendicular to its longitudinal axis. This has been referred to as lateral offset, lateral movement, parallel misalignment, direct shear or transverse movement. ANGULAR MOVEMENT (+/‐ DEGREES): This displacement of the longitudinal axis of the Expansion Joint from its initial straight line position into a circular arc. TYPES OF EXPANSION JOINTS: • Axial Expansion Joint • Lateral Expansion Joint • Hinge Expansion Joint • Gimbal Expansion Joint • Inline Pressure Balanced Expansion Joint • Elbow Pressure Balanced Expansion Joint • Externally Pressurized Expansion joint • Two ply testable bellow • Rectangular Expansion Joint • Slip Type Expansion Joint

Non Metallic Fabric Bellows

1,000 - 10,000 Per Nos

We are making customise non Mettalic fabric bellow.

Metal Bellows

150 Per Piece

non metallic bellow

468 - 1,548 Per piece

1 Piece (MOQ)

these are a profoundly adaptable connector shaped of normal or engineered texture. These non metallic bellows and tangled non metallic residue boots are adaptable seals utilized in wide scope of use that is intended to give pressure alleviation in the funneling business for warm developments and mechanical vibration. Both the roars have their own utility and significance. In the event that you rate on the size of Good, better and best. Among both metal roar and non metallic howls, metal cries with the rough numerous layer configuration are considered as the best. In view of its different layer plan, these cries are generally utilized in different mechanical applications in channeling industry. As they are considered as generally dependable and reliable for marine industry for quite a long time. Advantages of metal bellows : Higher pressure range: up to PN 100 Higher temperature range: up to 1000 °C Besides fluids and gases, also suitable for abrasive media and solids Flexible connection types possible Flexible extension possibilities Temperature : Non metallic bellows are constructed with the synthetic material under the temperature range to 230°F, Whereas a flexible metal bellows are designed from a great range from -420°F to +1800°F. However, working pressures are reduced at elevated temperatures.

Metallic Bellows

Get Price Quote

We are engaged in offering a wide range of Metallic Bellows which is extensively to stop dust particles, metallic chips and foreign particles from entering in the important parts of the machine. This helps in minimizing abrasion and provides longer life to the machine parts. Our product is manufactured using top quality raw material and is widely used in the industries.

Non-Metalic Bellow

500 - 5,000 Per nos

5 Piece (MOQ)

Metal Bellows

300 Per Piece

Metal Clad Bellow

1,500 Per Number

01 Number (MOQ)

Metal Flap Bellow

Get Price Quote

We are the notable Exporter and Supplier of Metal Flap Bellow based in Maharashtra (India). Procured from well-known vendors, our Metal Flap Bellows are in compliance with the laid industry norms and standards. Hence, they are widely used in milling machines, boring machines and welding machines. Buyers are free to place urgent as well as bulk orders with us. We are supported by a strong distribution network, which facilitates timely delivery of all the orders.Details : Fold + Stitched Bellows when fitted with metal 'Flaps' on the top or exposed face - become Metal Clad Bellows These bellows are suitable for extremely hot chip load conditions and can sustain sparks too Materials : PVC Coated Nylon Fabric + PVS Stiffeners + Metal FlapsShapes : All Squares & Rectangles 'C' & 'J' Shapes Tapering Shapes Applications : Milling Machines Boring Machines Welding Machines CNC

non metallic bellows

Get Price Quote

Ours is a reckoned name in this arena and capable to deliver high quality products to our worthy patrons. One can rely on us for the quality as our offerings are prepared using the best in class raw material. We are acknowledged for providing only damage-free products to the clients. For this, we make use of quality and tamper-free packing materials along with sophisticated packing machines. Features : Rugged construction Corrosion resistant Low operational cost