portable abrasive blaster

50,000 - 150,000 Per Piece

1 Piece (MOQ)

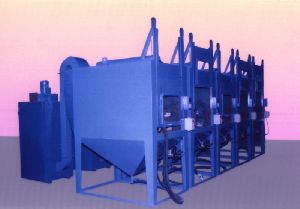

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

Best Deals from Abrasive Blasting Machine

abrasive blast equipment

Get Price Quote

abrasive blasting equipment, portable blasting machine, grit blasting

Abrasive Blasting Machine

125,000 Per Piece

Cabinet type abrasive blasting machine we are manufacturer of all types of abrasive blasting machines.

Abrasive blast cleaning machines

Get Price Quote

Pressure Abrasive Blasting Machine

Get Price Quote

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving

portable abrasive blasting machine

Get Price Quote

This is small abrasive portable blaster. This is required for repairing & maintenance purpose. In this system Abrasive storage capacity is up to 42 liters. In this model we use 5 mm tungsten carbide Nozzle & Blasting hose of 19 mm. Cleaning Rate of this model is Approx 3 – 4 Sq. meter.

portable abrasive blaster

Get Price Quote

The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. The operation is performed on metals, glass, ceramics, plastic and stone.The machine works on pressure blasting principle, consist of a blast generator. The abrasives are filled at the top of machine when machine is not working and blast generator is not pressurized. At the top, a vibrating sieve is provided to sieve the abrasive filled. The oversize abrasive and debris are retained on the screen, thus prevent the choking of blast line. When mushroom valve is opened the abrasive will get transferred to blast generator for blasting. The mushroom valve gets closed when compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. The Blast Generator is fabricated from MS Steel plate of thickness not less than 6 mm as per IS-2825 and hydraulically tested for 250 psi.

portable abrasive blasting machine

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving, Deflashing and cleaning.Portable abrasive blaster pressure feeds the system of abrasive propelling and results in higher production rates. The pressure vessels are tested to 250 psig and coded. Blast nozzles special design and tungsten carbides lined, result in long service life. It is equipped with high static and low weight blast hose. The remote control ON OFF is in operators' hand and requires no electric connection.

portable abrasive blaster

Get Price Quote

The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. The operation is performed on metals, glass, ceramics, plastic and stone.The machine works on pressure blasting principle, consist of a blast generator. The abrasives are filled at the top of machine when machine is not working and blast generator is not pressurized. At the top, a vibrating sieve is provided to sieve the abrasive filled. The oversize abrasive and debris are retained on the screen, thus prevent the choking of blast line. When mushroom valve is opened the abrasive will get transferred to blast generator for blasting. The mushroom valve gets closed when compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. The Blast Generator is fabricated from MS Steel plate of thickness not less than 6 mm as per IS-2825 and hydraulically tested for 250 psi.

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include deburring, descaling, peening, polishing, stress relieving

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone.

portable abrasive blaster

Get Price Quote

Brown Aluminum Oxides, White Fused Alumina, Acrylic Abrasive Blasting Media

portable abrasive blasting machine

Get Price Quote

Heavy Engineering Fabrication Service, air coolers oil coolers

Abrasive Blast Cleaning Machine

Get Price Quote

We are offering best Abrasive Blast Cleaning Machine

portable abrasive blaster

Get Price Quote