pressure blasting machine

Get Price Quote

portable blasting machine

Get Price Quote

Portable Blasting Machine high productivity and long life wear and tear parts as compare to others. The portable abrasive blaster is works on 'Direct Pressure System' resulting in very high cleaning rate and more economical system by Manual blasting, It's manufactured as per IS-2825 and hydraulically tested for 250 psi. The machine is supplied with long life tungsten carbide lined nozzle, anti-static blast-hose, alloy steel wear and tear parts, withwithout remote control for on off and remote control versions are denoted with suffix "R", Remote control system is complete pneumatic control, when handle is activated blasting begins and when the handle is released the system releases air from the machine to allow for filling of abrasives.

Best Deals from Blasting Machine

Diabola Type Shot Blasting Machine For LPG Cylinder, Shaft, Round Rods

3,000,000 - 3,500,000 Per Piece

1 Piece (MOQ)

Dual Cabinet Jeans Blasting Machine

460,000 Per piece

1 piece (MOQ)

Portable Sand Blasting Machine

75,000 Per Piece

1 Piece (MOQ)

portable sand blasting machines

30,000 Per Piece

1 Piece(s) (MOQ)

ABRABLAST PORTABLE SAND BLASTING MACHINE AB-P7-1001R AB-P7-501R AB-P7-301R AB-P7-150 With safety wear

portable abrasive blaster

Get Price Quote

Abrasive blast cleaning machines

Get Price Quote

tumblast machine

Get Price Quote

Standard Tumblast machines are the flexible, low-cost solution to batch clean tumble-proof components in the most efficient and economical way. This machine has multiple applications such as : It is used for the descaling of heat treated and forged parts. It can be used for the desanding of components which are either ferrous or non ferrous. It can be also used on metallic and non-metallic parts for deburring. Die cast parts can be deflashed with it. It can also be used for the removal of contamination. Features Compact design, simple operating principle Forced but gentle turning and tumbling of the parts for all-round shot impingement Targeted high performance shot blasting for specific applications Continuous and thorough shot removal The tumbling action of the belt conveyor ensures that components are continually exposed to the blast stream and completely cleaned. For easy unloading, the belt conveyor is reversed, delivering the components into the loading skip or stillage. Optimized shot blast effect During shot blasting, the work pieces, regardless of size and shape, are evenly and continuously tumbled. This is necessary for the effective and uniform treatment of all surfaces. During tumbling, the work pieces continually undergo shot removal, enabling work piece interiors and cavities to be perfectly cleaned For the complete removal of all shot, the final tumbling time that follows the shot blast sequence can be regulated to suit the type of work pieces being blast cleaned The tightly sealed, leak-proof blast chamber minimizes shot consumption Steel/Metallic conveyor or rubber belt conveyor (depending on machine size and application) Space-saving, ergonomic design Distortion-resistant rigid housing Process-appropriate blast chamber shielded with large, smooth, and highly wear resistant liners especially designed to withstand abrasion by shot impact Gravity /Rotary/ magnetic separation systems Special design for use of aluminum abrasive Removal of shot, sand, or scale via screw conveyor Magna valves (optional) Ergonomic maintenance platform Adequate loading / unloading systems Dust removal system

Swing Table Type Shot Blasting Machine

1,500,000 - 3,500,000 Per INR

We offer a wide range of Swing Table Type Shot Blasting Machine to customers situated in India, UAE, Saudi, Sri Lanka and Australia. It is fabricated using superior grade raw materials and advanced machinery to guarantee its durability and high performance. Our Swing Table Type shot Blasting Machine has automatic operation and can be supplied in single as well as double doors with table. We also make available Swing Table and drum doors combination.

Tunnel Type

Get Price Quote

A range of airless shot blasting machine, 'tunnel type' with number of blast wheels varies according to the production output available. This is the most used and flourishing series for the long structural, channels, angles, plates, gratings, pipes.

Shot Blasting Machine

Get Price Quote

We are offering Shot Blasting Machine that is widely used in many industries for blasting purposes. Our Shot Blasting Machine is manufactured in compliance with the set industrial standards. We make use of only the best components in the market to assemble our machines. Further, this Shot Blasting Machine has latest features, which are helpful and safe to use. Highlights : Durable Easy to operateInstalled with latest features

Sand Blasting Machine

68,000 Per Piece

Portable sand blasting machine p7 . We are manufacturer of sand blasting machine, shot blasting machine, cabinet type blasting machine,

Portable Sand Blasting Machine

Get Price Quote

01 Piece(s) (MOQ)

We are offering portable sand blasting machine. Surface treatment equipments are listed among the foremost sand blasting machine manufacturer, exporter and supplier. We offer industrial grade sand blasting machine, which is equipped with wear resistant spares which make them anti abrasive and anti-corrosive in nature. Equipped with blasting nozzle exhaust valve automatic tank sealing air filters pressure gauge choke valve pinch valve mixing tube assembly nozzle holder hose connector this ma used for cleaning of pipes and vessels cleaning of sculptures and monuments cleaning of bridges, tanks, removal of rust, corrosion and scales re-conditioning and surface preparation before painting cleaning of structural steel

portable blasting machine

60,000 Per Piece

2 Piece (MOQ)

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

BU vacuum blasting machine

Get Price Quote

1 Piece (MOQ)

airless blasting machine

Get Price Quote

Our organization is renowned as reliable distributor in the industry and based in the well-connected state of Rajasthan(India). Due to our secure and hassle-free payment procedures, clients stay satisfied with us. We undertake both online and offline payment processing methods including cash and bank transfers.

portable blasting machines

Get Price Quote

This is small abrasive portable blaster. This is required for repairing & maintenance purpose. In this system abrasive storage capacity is up to 42 liters. In this model we use 5 mm tungsten carbide nozzle & blasting hose of 19 mm. Cleaning rate of this model is approx 3 – 4 sq. Meter.

Diabolo Shot Blasting Machine

Get Price Quote

SURFEX introduced low cost Shot Blasting Machine for cleaning of Rods / Bars. The use of this machine is recommended for replacing acid pickling process which is environmentally hazardous hence banned by Central Pollution Control Board (CPCB) of India. The Machine is provided with singleBlast Wheel Station mounted on Blast Cabinet. The Dia-Bola type of conveyor system is provided for rotating as well as moving forward the Rods / Bars. The Rods are fed on dia-bola which convey the same into Blast Chamber, there it is shot blast / cleaned. The blast / cleaned Rods come out from outlet side of blast cabinet. The machine is continuously operating single rod process system. The production rate upto 4 to 5 per meter per minute can be achieved. The machine can also be provided for feeding 2 rods at a time, hence output is doubled. The machine is equipped with effective shots recovery & cleaning system and dust collector conform to Central Pollution Control Board (CPCB) norms. The entire operation of machine is controlled by control panel.

Micro Blasting Machine

Get Price Quote

We have Micro Blasting Machine for drill bits & tool. Thin layer of oxide deposits on drill bits & tools. To blast clean that oxide layer mec shot has developed plc controlled automatic micro blast cleaning machine. the operator place the job on satellites/ spindle. The indexing turn table carries it into blast chamber where satellite starts rotating. Each satellite have 8 spindles & rotates when come in contact of friction of timing belt. features: vertical gun reciprocation horizontal lead screw inching system plc-for sequence operation & parameter repeatability. indexing turn table with satellite/spindles cartridge type dust collector & reclaimer.

airless shot blasting machine

Get Price Quote

TumBlast comes with motorized tumbler fitted to endless belt in blast chamber, to form a cupped shaped tumble. It runs at a constant speed through gear assembly. Job is loaded on the belt manually or automatically through automatic loader (optional). Now, blasting is done through centrifugal blast wheel mounted on top of blast cabinet. Blast media id transferred through the perforated belt to the hopper and further to the bucket elevator via screw conveyor. Media separation unit is deployed to separate dust and usable media, which is fed again to the blast wheel.

grit blasting machine

Get Price Quote

We are One of the Leading Grit Blasting Machine Manufacturers and Exporters in the Industry. the Grit Blasting Machine is in High Demand in the Market Owing to Its Accurate Profile and Dimensional Accuracy. Competitively Priced and High Quality Grit Blasting Machine Has Placed Us in the Elite Group of Grit Blasting Machine Manufacturers and Suppliers from India.

Rotary Barrel Machine

350,000 Per Set

1 Set(s) (MOQ)

This machine is probably the smallest in the family of Airless Machines, and miniature version of Tumblast Machine (power consumption is very low 5 HP only). Specially designed for cleaning of Small/Medium size Iron, Steel, Alloy, and Non-Ferrous Casting, Forging, Heat treated Parts etc. Hence it is ideal for foundries, forging unit and small job shops where less space is required and economic production is concerned. The Machine has rotatory barrel type (Size: 649 mm Dia x 625 mm Length) with thick perforated rubber sheet. The door is opened and components are fed into the machine. The barrels rotate at low rpm and tumbling action, which also ensures the safety of the components. The powerful Blast wheel fires shots on the components and uniform blasting is done. The machine is controlled by control panel and electronic timer. Also, abrasive Recollection System along with Dust Collector (dry type) is also provided as standard fitment.

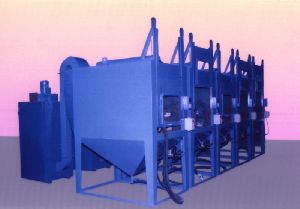

Blasting Rooms

Get Price Quote

Blast room equipment is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The surface of the work piece is cleaned by a mixture of abrasive and high pressure compressed air being directed on to the work piece by blast nozzle. The blast room contains the abrasive being shot at the work piece, as well providing lighting and ventilation for the operator's safety. MEC offer a variety of blast room designs and room configuarations which allow to design a blast room facility uniquely tailored to meet the economic production, safety and environmental concerns of each customer. The modular blast room is specially ventilated and illuminated for enclosed abrasive blasting, and is fully sealed, dust tight, all steel structure. The components are prefabricated for simple bolt-together erection, with little or no site welding required. The enclosure stands by it's own structural support without connections to the surrounding facilities. The size of the job depends on

Pavers Block Shot Blasting Machine

500,000 Per Piece

1 Piece(s) (MOQ)

paver block shot blasting machine

500,000 Per Piece

1 Piece(s) (MOQ)

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include deburring, descaling, peening, polishing, stress relieving

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving

Blast Room

Get Price Quote

01 Set(s) (MOQ)

We are offering Blast Room. Easy to install easy to use zero dust leakage fully grit recovery system fully dust exhaut system.