2 HP Shot Blasting Machine

225,000 Per piece

1 piece (MOQ)

Pneumatic shot blaster machine

Get Price Quote

We are leading manufacturer of Pneumatic shot blaster machine. Our products are in different segments

Best Deals from Blasting Machine

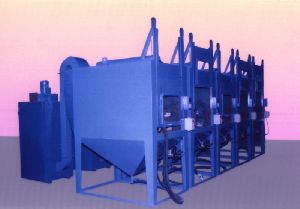

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

Overhead Rail Shot Blast Machine

Get Price Quote

Surface International manufacturers continuous overhead conveyor shot blast machines which can be used for a wide spectrum of applications and work piece shapes and sizes. Characteristics Versatile transport technology Highly efficient blast wheels Multiple machine sizes and variations available Applications Removal of mill and forge scale as well as rust Removal of burrs and scales Removal of molding sand Increase of surface roughness Applications include blast cleaning welded steel fabrications, deburring and homogeneous die-cast parts, and peening dynamically stressed components. Batches of small components or singular large, heavy work pieces can be treated. This flexibility is achieved by several special features : Rotation and oscillation To achieve complete coverage, the work piece carrying hooks rotate and stop automatically at different location in the blast chamber. This rotation and oscillation process means that even highly complex work pieces, with hard to reach surfaces, can be safely and accurately treated. Hook and hoist options The transport system can be designed for different size & weights. As an option, carrying hooks are available with integrated chain hoists for operational ease and safety. The Process The work pieces are transported manually on rotating hooks or automatically on an overhead rail system into the blast cabinet. The blast cycle runs in accordance with the preset program and blast time. Used abrasive and fines fall through the abrasive collection hopper beneath the blast cabinet and are transported via a screw conveyor to a bucket elevator and to the abrasive reclamation unit. In the reclamation unit, the used abrasive is separated from fines and contaminants and returned to the abrasive silo. The screw conveyor to provide targeted cleansing/ separating of sand and heavy contaminants from the used abrasive. The conveyor should ideally be installed with a magnetic separator (also optional) to remove sand in order to prolong the service life of the machine. The abrasive then goes to the air wash separator as before. Manually Operated Monorail As standard, the monorail system is designed in a single or Y-shape and equipped with two carrying hooks made from manganese steel. The work piece batches are manually pushed to the door of the shot blast machine where they are automatically taken by a feeding system. For especially heavy work pieces there is the option to install an automatic transport facility over the whole length of the overhead rail system. Lifting Gears Depending on the work pieces to be treated, and the preceding and subsequent processes, it may be advantageous to combine the carrying hooks with a chain hoist so that work piece batches or heavy parts can be easily picked up. The chain hoist is operated directly at the loading/unloading station of the overhead rail system. Blast Cabinet with wear resistant lining The blast cabinet of this machine is completely lined from manganese steel. The advantage of manganese steel: it is hardened by the impact of round abrasive from 20 HRC to more than 50 HRC, so it has extremely good wear characteristics. Wear plates around the �hot spot� provide additional protection for the cabinet. Made from 10 mm thick manganese steel, they overlap, suspended on a carrying system. To seal the cabinet, a slot seal is integrated in the machine roof to avoid the escape of abrasive from the monorail slot. The sealing system consists of a manganese steel labyrinth with a double rubber lip and additional strip brushes. Abrasive Removal During the blast process, dust, broken abrasive and other solid particles or contaminants (fines) are generated by the rust and scale removed from the work pieces. The fines are separated in the abrasive reclamation unit which is individually adjustable to the different types and sizes of abrasive. The Abrasive reclamation unit consists of an impact separator and a cartridge filter. The cartridge filter provides the necessary negative pressure to remove dust. It is installed separately beside the shot blast machine.

Swing Table Type Shot Blasting Machine

1,500,000 - 3,500,000 Per INR

We offer a wide range of Swing Table Type Shot Blasting Machine to customers situated in India, UAE, Saudi, Sri Lanka and Australia. It is fabricated using superior grade raw materials and advanced machinery to guarantee its durability and high performance. Our Swing Table Type shot Blasting Machine has automatic operation and can be supplied in single as well as double doors with table. We also make available Swing Table and drum doors combination.

abrasive blast equipment

Get Price Quote

abrasive blast equipment, shot peening equipment

High Speed Airless Blast Wheel

Get Price Quote

MECShot has introduced a new wheel which gives an increased blast pattern and cleaning area. The casing is protected with wear resistant liners. Whole wheel assembly is designed in such a way that it is compact and easy for maintenance.

Hanger Type Shot Blasting Machine

Get Price Quote

To blast clean automatically wide varitey of work pieces."ABRABLAST" has a range of airless shot blasting machin Hnager type with number of blast wheels varying according to the job size for the wide variety of work pieces for large prduction output in terms of surface treatment . THE OVERHED CONVEYOR CARRIES THE JOB IN & out of the blast cabinet where numbers of blast wheel are located depending upon the type of the job for attaing homogemenos finish.major parts of the machine include blast wheel for giving high prodcution output, over head conveyor for job conveyinng & the media recovery , consist of bucket elevetor screw conveyor rotary screen seprator etc. & dust collcetor.The machine is desinged for auotmatic efficeint shot blasting of aluminium casting . The job is loaded on the hanger in the blasting cabinet wher they are blasted inside the chamber. The speed of the hanger drives can be regulated by AC drives The cabinet is protected from erosion by liners ( Hardened wear plates ), mounted on the side walls , top & doors.The dust particles generated in the system are collected in a number of pleated bags in dust collector , clean aur is exausted throgh fan. The pleated bags are cleande by pulse type recers jet air cleaner controlled throg h solenoid valve and the collected dust particules fall in a dust bin and taken out for disposal from time to time.The dust particles genrated in the systems are collected in a number of pleated bags are cleaned by pulse type revrsse jet air cleaner controlled through solenoid valve and the collected dust particles fall in a dust bin and taken out for disposal from time to time. Models Hanger Type Shot Blasting Machine Ex-works Price – 7.5 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month –4 Nos Ab- Y-hanger Type Shot Blasting Machine Ex-works Price – 11.50 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 4 Nos Continues Hanger Type Shot Blasting Machine Ex-works Price – 18.0 Lac Processing Time – 6 Week Minimum Order Qty – 1 Supply Ability Per Month – 3 Nos Ab-Ash-monorail Type Shot Blasting Machine Ex-works Price – 16.0 Lac Processing Time – 6 Week Minimum Order Qty – 1 Supply Ability Per Month – 3 Nos Ab-Ash-close Loop Hanger Type Shot Blasting Machine Ex-works Price – 19.0 Lac Processing Time – 7-8 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Ab-Ash-t Hanger Type Shot Blasting Machine Ex-works Price – 12.0 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Ab-Ash-1 Shot Blasting Machine Ex-works Price – 6.5 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 5 Nos Ab-Ash-6 Shot Blasting Machine Ex-works Price – 7.5 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 5 Nos Ab-Ash-8 Shot Blasting Machine Ex-works Price – 9.5 Lac 10.0 Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 3 Nos

Sand Blasting Machine

68,000 Per Piece

Portable sand blasting machine p7 . We are manufacturer of sand blasting machine, shot blasting machine, cabinet type blasting machine,

portable blasting machine

60,000 Per Piece

2 Piece (MOQ)

Abrasive blast cleaning machines

Get Price Quote

Shot Blasting Machine

Get Price Quote

We are offering Shot Blasting Machine that is widely used in many industries for blasting purposes. Our Shot Blasting Machine is manufactured in compliance with the set industrial standards. We make use of only the best components in the market to assemble our machines. Further, this Shot Blasting Machine has latest features, which are helpful and safe to use. Highlights : Durable Easy to operateInstalled with latest features

BU vacuum blasting machine

Get Price Quote

1 Piece (MOQ)

Portable Sand Blasting Machine

Get Price Quote

01 Piece(s) (MOQ)

We are offering portable sand blasting machine. Surface treatment equipments are listed among the foremost sand blasting machine manufacturer, exporter and supplier. We offer industrial grade sand blasting machine, which is equipped with wear resistant spares which make them anti abrasive and anti-corrosive in nature. Equipped with blasting nozzle exhaust valve automatic tank sealing air filters pressure gauge choke valve pinch valve mixing tube assembly nozzle holder hose connector this ma used for cleaning of pipes and vessels cleaning of sculptures and monuments cleaning of bridges, tanks, removal of rust, corrosion and scales re-conditioning and surface preparation before painting cleaning of structural steel

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving

Hanger Blast Room

Get Price Quote

Our Hanger Type Blast Room and airless shot blasting machine suitable for cleaning of varieties of small and big, regular & irregular structures which sometimes cannot be conveyed on rollers or diabola types of conveyors. The machine is most suitable for the jobs like transformer tanks, small cylinders, cylinder heads, alloy wheels and various small complicated structures for homogenous cleaning. the machine comes in different versions depending upon the conveying mechanism of the jobs for example 'y' hanger type, 't' hanger type, closeloop/continuos hanger type, inline overhanging conveyor. Jobs can be conveyed into the blasting chambers either through the hanger on the doors or through the monorail overhead conveyor. The type of the overhead conveyor and the number of the blast wheels are determined by the kind of the dimensions of the jobs and the production output required. essential elements: blast wheel assembly. shot blasting chamber with mm lining/rubber lining. abrasive re-circulation consisting of screw conveyor, bucket elevator, rotary screen separator & dribble valve. dust collection system - pulse jet type. monorail conveyor / doors with hanger.

airless shot blasting machine

Get Price Quote

Surfex’ Airless Shot Blasting Machine Rotary Barrel Type‘Surfex Airless Shot Blasting Machine Rotary BarrelType complete with Elevator, Abrasive Recycling System, Control Panel, Electric Motors, Fabric Bag Type Dust Collector Unit, Capacity 1200 Cfm. with Load Carrying Capacity175 Kg.Operating Principle :The machine consists of Rotary Barrel lined with perforated rubber sheet. The barrel is loaded with components. The barrel rotate at low rpm and gently tumble components. A powerful Blast Wheel Unit is fitted at the bottom of barrel which fires shot on tumbling components and blast them thoroughly. The door of barrel is opened and blasted components are taken out. The machine is fully ventilated by Dry Type Fabric Bag Dust Collector. The machine is recommended for small to medium size components. Leading Technical Specification: Note: Above specifications are subject to change due to continuous development of product.

Blasting Rooms

Get Price Quote

Blast room equipment is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The surface of the work piece is cleaned by a mixture of abrasive and high pressure compressed air being directed on to the work piece by blast nozzle. The blast room contains the abrasive being shot at the work piece, as well providing lighting and ventilation for the operator's safety. MEC offer a variety of blast room designs and room configuarations which allow to design a blast room facility uniquely tailored to meet the economic production, safety and environmental concerns of each customer. The modular blast room is specially ventilated and illuminated for enclosed abrasive blasting, and is fully sealed, dust tight, all steel structure. The components are prefabricated for simple bolt-together erection, with little or no site welding required. The enclosure stands by it's own structural support without connections to the surrounding facilities. The size of the job depends on

Shot Blasting Equipment

Get Price Quote

Shot blasting equipment in offering customized Fabrication Work machines and components at highly competitive prices. Shot Blasting Equipments is a manufacturer of Air operated Airless Shot Blasting Machines, ..

Pressure Abrasive Blasting Machine

Get Price Quote