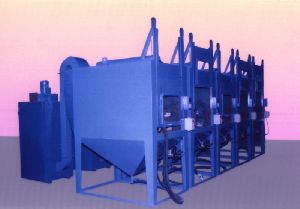

BU vacuum blasting machine

Get Price Quote

1 Piece (MOQ)

Portable Sand Blasting Machine

Get Price Quote

We manufacture all types of shot blasting machines both standard and special purpose. Our product range is shown below. We advice suggest a suitable model for your application in terms of job size weight, material production volume etc hence to know your requirement please fill in the enquiry form & submit to us.

Best Deals from Blasting Machine

Portable Sand Blasting Machine

Get Price Quote

01 Piece(s) (MOQ)

We are offering portable sand blasting machine. Surface treatment equipments are listed among the foremost sand blasting machine manufacturer, exporter and supplier. We offer industrial grade sand blasting machine, which is equipped with wear resistant spares which make them anti abrasive and anti-corrosive in nature. Equipped with blasting nozzle exhaust valve automatic tank sealing air filters pressure gauge choke valve pinch valve mixing tube assembly nozzle holder hose connector this ma used for cleaning of pipes and vessels cleaning of sculptures and monuments cleaning of bridges, tanks, removal of rust, corrosion and scales re-conditioning and surface preparation before painting cleaning of structural steel

paver block shot blasting machine

500,000 Per Piece

1 Piece(s) (MOQ)

hook shot blasting machine

250,000 Per piece

1 piece (MOQ)

Shot Blasting Machine

800,000 - 1,000,000 Per one

1 Piece (MOQ)

Tunnel Shot Blasting Machines

Get Price Quote

To descale mild steel plate & structurel section prior to painting."ABRABLAST" has a wide range of Airless Shot Blasting Machine Tunnel Type With numbers of Blast Wheels to suit the Job Size and according to Productin output required. This is the mostly used to Blast Clean long structural members, channels, angles, gratings, pipe fabricated components etc. for large production output for removing rust and to achieve superior quality (approx. Sa2/Sa2.5 SSPC standaerds) finish after blast cleaning prior to painting.The opening of the tuunel & required number of blast wheels depends upon the structure of job for attaching homogeneous finish.Major assemblies of the machine are blast wheels for giving high production output, roller conveyor for job conveyoing & media recovery consists of bucket elevetor , screws conveyors , rotary screen separators , abrasive storage hopper etc. & pulse jet type dust collectors is less than 10 miiligram per cubic meter.the works pieses is to be placed as far as possible in the centre of the guides of rolers on in feed conveyor when the rollers are not in rotating. The possition of work pieses is in such a way that it can rolled easily hrizontal as shown in phtograph , to avoid the accumulation of shots . After then it passes throgh entry vestibule tunnel and then enters into the blasting chambner for blast clean process . If the prefabricated structure can not be rolled on the rollers then it has to be kept either on predesinged fixture or a trya enabling it to travel & pass through the blast cabinet.Blast wheel stations are aranged strategically around and located on the top of cabinet propels abrasive on the rolling works pieces. The blower arrangment continuely blow- off abrasive accumlated on the top side of the work piece . After shot blasted homogeneously finished all around air washed work pieces rolls out from exit vestibules tunnel to the out feed conveyor rollers , from where it is to be unloaded manually . The operatons of squence is details programmed for ease of operaton and to achive the required performance. Tunnel Type Shot Blasting Machine Ex-works Price – 15.0 Lac To 20.0 Lac Processing Time – 8 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Stone Shot Blasting Machine Ex-works Price – 12.0 To 18.0 Lac Processing Time – 5-6 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Structure Shot Blasting Machine Ex-works Price – 30.0 Lac To 45.0 Lac Processing Time – 48week Minimum Order Qty – 1 Supply Ability Per Month – 3 Nos Paver Block Shot Blasting Machine Ex-works Price – 8.0 Lac To 12.0 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 4 Nos Rod Bar Cleaning Shot Blasting Machine Ex-works Price – 15.0 Lac To 16.0 Lac Processing Time – 5-6 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Pipe Cleaning Shot Blasting Machine Ex-works Price – 14.0 Lac To 16.0 Lac Processing Time – 6 Week Minimum Order Qty – 1 Supply Ability Per Month – 3 Nos Fabricated Structure Shot Blasting Machine Ex-works Price – 25.0 Lac To 35 Lac Processing Time – 7-8 Week Minimum Order Qty – 1 Supply Ability Per Month – 2 Nos Stone Texuring Shot Blasting Machine Ex-works Price – 13.0 Lac To 15.0 Lac Processing Time – 4 Week Minimum Order Qty – 1 Supply Ability Per Month – 3 Nos

Suction Air Blasting Machine

Get Price Quote

Super Blaster Machine works on suction principle of lifting abrasive media to the blasting gun. High pressure compressed air when injected through venturi creates suction on the side of air injection. This suction pressure so created is used to lift abrasives which mix with the high velocity compressed air creating soft blasting. These super blaster machines are used for glass bead blasting, alumina blasting of soft metals like aluminum di-casting, carving on glasses, roughening of stones. Various standard and special size machines are available for selection. Suction Blaster Operating Principal Suction Blaster is the simplest and most effective way to remove corrosion and old paint. Suction Blaster is a clean, dust free sand blaster that leaves the surface cleaned and well prepared for painting, filling etc. When the cabinet and power module is correctly set-up, the cabinet is ready for operation by actuation of the foot pedal. After pressing the foot pedal air flows through the blast gun. Air moving through the gun draws media into the blast gun mixing chamber. The media mixes with the air and is propelled out the nozzle. After striking the object being blasted, the blast media, along with fines, dust, and byproducts generated by blasting, fall through the grate into the cabinet hopper. These particles are drawn into the reclaimer for separation. Dust and fines are first separated from the reusable blast media. Next the media is screened of oversize particles, and returned to the reclaimer hopper for reuse. Dust and fines are drawn from the reclaimer into the dust collector which traps the dust, discharging clean air. When the foot pedal is released the blasting stops.

Rotary Barrel Type Shot Blasting Machine

300,000 - 600,000 Per Set

abrasive blast equipment

Get Price Quote

abrasive blast equipment, NON STICK COOKWARE BLASTING MACHINE

High Speed Airless Blast Wheel

Get Price Quote

MECShot has introduced a new wheel which gives an increased blast pattern and cleaning area. The casing is protected with wear resistant liners. Whole wheel assembly is designed in such a way that it is compact and easy for maintenance.

Abrasive blast cleaning machines

Get Price Quote

portable blasting machine

60,000 Per Piece

2 Piece (MOQ)

Sand Blasting Machine

68,000 Per Piece

Portable sand blasting machine p7 . We are manufacturer of sand blasting machine, shot blasting machine, cabinet type blasting machine,

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

wet blasting machine

Get Price Quote

It is self-contain System which uses slurry of Abrasive Media & water to clean, descale and degrease surfaces in a single operation. The slurry is directed through a special high volume pump to blast gun where regulated air pressure adjusts the aggressiveness of the process. The process is free of dust and is close-loop. Water acts as a buffer between metal & media to cushion the shock on delicate components. This WET SHOT BLASTING MACHINE is recommended for degreasing & Blast Finishingof delicate jobs. In this method cabinet hopper contains the slurry of abrasive and liquid. The slurry is continuously agitated to ensure a through mining of the abrasive and the liquid. The slurry is drawn up by pump through flexible pipe to the nozzle of the blast gun. Where it is propelled by compressed air to increase the velocity. The stream of abrasive, suspended in a liquid is projected at high velocity through a gun. The fired slurry from nozzle gets collected into the hopper like bottom of blast cabinet. From where it is passed to slurry pump for recycling. The quantity of slurry to the blast nozzle can be controlled through the valve provided inside the blasting chamber. An arrangement with the help of washing gun will be provided for cleaning of job after micro wet blasting.

Pavers Block Shot Blasting Machine

Get Price Quote

Mtek shot blasting equipments has recently designed and manufactured a new shot blasting conveying machine for cement concrete interlocking paving blockssand stonemarble panelsgranites.

Sand Blasting Machine

Get Price Quote

01 Set(s) (MOQ)

Automatic sand blasting machine quick start sand blasting machine easy to use sand blasting machine best quality sand blasting machine portable sand blasting machine easy to fill sand in sand blasting many capacity are abailability of sand blasting machine.

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include deburring, descaling, peening, polishing, stress relieving

Blast Room System

Get Price Quote

We are reckoned as one of the prominent blast room system manufacturers in india. The airless blast room system is ideally designed to effectively blast clean big components. The blasting room system is equipped with proper light, dust collector, main door with louvres and portable blasting machine. The recovery system of the blast room can be mini hopper type where in the abrasives falling in to the hopper are carried to the cyclone with suction air current. These abrasives get cleaned during the process & re-circulated. the other type of recovery system is mechanical recovery system with screw conveyors & bucket elevators. The system also conveys the material to the blasting machine through screw conveyor & bucket elevator system and the abrasives get cleaned in the course of movement to the portable blasting machine.