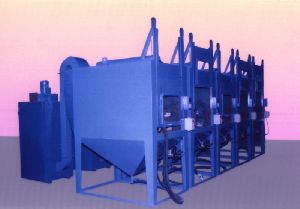

Suction Air Blasting Machine

Get Price Quote

Super Blaster Machine works on suction principle of lifting abrasive media to the blasting gun. High pressure compressed air when injected through venturi creates suction on the side of air injection. This suction pressure so created is used to lift abrasives which mix with the high velocity compressed air creating soft blasting. These super blaster machines are used for glass bead blasting, alumina blasting of soft metals like aluminum di-casting, carving on glasses, roughening of stones. Various standard and special size machines are available for selection. Suction Blaster Operating Principal Suction Blaster is the simplest and most effective way to remove corrosion and old paint. Suction Blaster is a clean, dust free sand blaster that leaves the surface cleaned and well prepared for painting, filling etc. When the cabinet and power module is correctly set-up, the cabinet is ready for operation by actuation of the foot pedal. After pressing the foot pedal air flows through the blast gun. Air moving through the gun draws media into the blast gun mixing chamber. The media mixes with the air and is propelled out the nozzle. After striking the object being blasted, the blast media, along with fines, dust, and byproducts generated by blasting, fall through the grate into the cabinet hopper. These particles are drawn into the reclaimer for separation. Dust and fines are first separated from the reusable blast media. Next the media is screened of oversize particles, and returned to the reclaimer hopper for reuse. Dust and fines are drawn from the reclaimer into the dust collector which traps the dust, discharging clean air. When the foot pedal is released the blasting stops.

Abrasive blast cleaning machines

Get Price Quote

Best Deals from Cleaning Machine

Internal Pipe Cleaning Tool

45,000 Per Piece

20 Piece (MOQ)

suction blaster

Get Price Quote

We are offering suction blaster. The suction blaster is work on induction-suction principle of abrasive delivery. It is mainly useful for fine and medium matte finish on soft and plastic material in wide range of heat treatment shops, too, die and mould makers and shot peening of light metal components etc.

Piston Cleaning Machine

Get Price Quote

We have Piston Cleaning Machine. The various types and sizes of piston rings are required to be cleaned as part of manufacturing process to create desired surface roughness for subsequent coating operations. The task of blast cleaning is performed either by dry blast cleaning or wet blast cleaning process. The piston rings I.D./ O/D. Are cleaned by propelling high-speed abrasive media on the surface with the help of compressed air. As a result, the contaminants/scales/rust etc. Is removed and nascent metal is exposed on the surface. The selection of abrasive depends upon surface roughness required. However, use of finer size of aluminium oxide grit and glass beads (minute spherical glass balls) as abrasive blasting media is quite common. The equipment is Closed Type Cabinet along with Automatic Abrasive Recycling and featured with provision of motorized mandrel rotation and nozzle reciprocation through hydro-pneumatic arrangement with adjustable stroke facility with the help of limit switches. The dust generated during blasting process is collected in Fabric Bag Type Dust Collector Housing or Paper Filter Element Cartridge Reverse jet Type Dust Collector in Dry Blasting Machines. However, provision of Water Wash Gun, Slurry Agitation, Water Separator System & Mist Collector are the standard features of this equipment.

strip cleaning machine

Get Price Quote

STRIP CLEANING MACHINE Strip cleaning machine are used for stainless steel,descaling of carbon steels. This machine consist of multiple centrifugal blast wheels each of them driven by individual motors to give a through cleaning. The jobs kept on suitable conveying system with variable speed flexibility. The jobs enters the blast cabinet for cleaning from abrasives fired by multiwheels for homogenous finish. Operation:The strip is fed from de-coiler to inward side of tunnel /vestibule of pinch rollers of shot blasting machine. Then the strip enters into blasting chamber for blasting operation/purpose.8 no of blast wheel stations are located strategically on to blasting cabinet.(i.e 4 wheels are located on top of blasting cabinet and 4 wheels are located on to bottom portion of blasting cabinet) .the blasted /cleaned strip moves forward and enter into out let tunnel/ vestibule. From there strip is pulled by coiler and other equipment (arranged by customer).The machine is designed for cleaning strip @ 60 mtr per minutes. Operating Principle :The machine entails robust and sturdy Blast Cabinet on which 8 Nos. of Blast Wheel Station are located at descaling angle. The cabinet is also equipped with Abrasive Recovery & Cleaning System and Dust Collector for ventilating Blast Cabinet. The strip is fed from decoiler to inward side of tunnel through pinch roller of Shot Blasting Machine. The strips enters into Blasting Chamber for Blast cleaning application. 8 Nos. of Blast Wheel Stations cleans the strips from both sides in single pass. The strip is pulled by Coiler and other equipment and adjustable as per requirement. Maximum Coil Strip is of 60 mtrs. per minute can be achieved. The entire operation of machine is meticulously controlled by PLC.

Balaji Tyre Mould Cleaning Machine

1,500,000 Per piece

1 piece (MOQ)

Suction Blaster Machine

Get Price Quote

1 Machine (MOQ)

Ultrasonic Therapy Machine

3,000 Per Piece

1 Piece(s) (MOQ)

Abrasive Blast Cleaning Machine

Get Price Quote

We are offering best Abrasive Blast Cleaning Machine

Internal Pipe Cleaning Blasting Machine

Get Price Quote

Floor Cleaner

Get Price Quote

Floor Cleaner, swimming pool chemical, cane washing chemicals

Abrasive Blast Cleaning Machine

Get Price Quote

Abrasive Blast Cleaning Machine, End Draft Type Paint Spray Booth

Suction Blaster Machine

Get Price Quote

Suction Blaster Machine, SEND BLASTING SQURE PART, CYCLONE