suction blaster

150,000 - 405,000 Per Piece

1 Piece (MOQ)

Suction Blaster Machine

Get Price Quote

1 Machine (MOQ)

Best Deals from Cleaning Machine

Internal Pipe Cleaning Tool

45,000 Per Piece

20 Piece (MOQ)

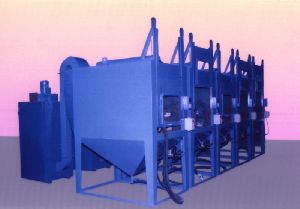

strip cleaning machine

Get Price Quote

Steel Strip Shot Blasting Machines are specifically designed to treat steel strips (carbon, alloy or stainless steel) on a continuous passage under the blast streams at the speed required by customer. This machine consists of multiple centrifugal blast wheels each of them driven by individual motors to give a thorough cleaning. The jobs kept on suitable conveying system with variable speed flexibility. The strip is fed from de-coiler to shot blasting machine. Then the strip enters into blasting chamber for blasting, blast wheel stations are located strategically on to blasting cabinet. The cleaned strip moves forward and enters into out vestibule. From there strip is pulled by coiler. The entire operation of machine is controlled by PLC. Â

Abrasive blast cleaning machines

Get Price Quote

Mould Cleaning Machine

Get Price Quote

The Mould Cleaning Machine has engineered for uniform surface finishing of glass tube mould for television to achieve surface finish within close range of + 0.5 ra in single operation. the machine consists of large blast chamber fitted with doors for easy access with pitless pneumatic recovery system as well as high level of internal illumination. the enclosure has a white, reflective inner surface to enhance the operator's visibility. The vision glass is made from toughed safety glass. the machine incorporates automated workcar with rotary table for "in & out" of moulds from the enclosure. Oscillating arms mounted with multi blast nozzles for covering the complete job, profile/surface. The motion of oscillating norms is synchronized with rotary table rpm for consistent surface finish. such heavy duty machines can operate 24 hours a day, 7 days of week. The inside walls and turntable are lined with uhmw material and all gun holder, gun rods, gun arms and tooling are made of hardened steel for long service life. The machine is also featured with plc and electronic panel view for operational sequence parameters selection and fault finding. The components are cleaned by automatic air purging after blasting. High efficiency reversejet filter elements cartridge type dust collector ensure that air exhausted is maintained at high level of cleanliness.

strip cleaning machine

Get Price Quote

STRIP CLEANING MACHINE Strip cleaning machine are used for stainless steel,descaling of carbon steels. This machine consist of multiple centrifugal blast wheels each of them driven by individual motors to give a through cleaning. The jobs kept on suitable conveying system with variable speed flexibility. The jobs enters the blast cabinet for cleaning from abrasives fired by multiwheels for homogenous finish. Operation:The strip is fed from de-coiler to inward side of tunnel /vestibule of pinch rollers of shot blasting machine. Then the strip enters into blasting chamber for blasting operation/purpose.8 no of blast wheel stations are located strategically on to blasting cabinet.(i.e 4 wheels are located on top of blasting cabinet and 4 wheels are located on to bottom portion of blasting cabinet) .the blasted /cleaned strip moves forward and enter into out let tunnel/ vestibule. From there strip is pulled by coiler and other equipment (arranged by customer).The machine is designed for cleaning strip @ 60 mtr per minutes. Operating Principle :The machine entails robust and sturdy Blast Cabinet on which 8 Nos. of Blast Wheel Station are located at descaling angle. The cabinet is also equipped with Abrasive Recovery & Cleaning System and Dust Collector for ventilating Blast Cabinet. The strip is fed from decoiler to inward side of tunnel through pinch roller of Shot Blasting Machine. The strips enters into Blasting Chamber for Blast cleaning application. 8 Nos. of Blast Wheel Stations cleans the strips from both sides in single pass. The strip is pulled by Coiler and other equipment and adjustable as per requirement. Maximum Coil Strip is of 60 mtrs. per minute can be achieved. The entire operation of machine is meticulously controlled by PLC.

Bar Cleaning Blasting Machine

Get Price Quote

The offered range is made utilizing optimum grade raw material, sourced from certified vendors of the market. In addition to this, the offered range is available in different designs, shapes and allied specifications in accordance with the assorted demands of clients.

Internal Pipe Cleaning Blasting Machine

Get Price Quote

Abrasive Blast Cleaning Machine

Get Price Quote

We are offering best Abrasive Blast Cleaning Machine

Toilet Cleaner

Get Price Quote

Housekeeping Cleaning Chemicals, Water Softening Plant

Toilet Cleaner

Get Price Quote

Dishwash Gel

Wheat Cleaning Gravity Machine

Get Price Quote

Wheat Cleaning Gravity Machine, Spice Processing Plant

Suction Blaster Machine

Get Price Quote

Suction Blaster Machine, SEND BLASTING SQURE PART, CYCLONE

Abrasive Blast Cleaning Machine

Get Price Quote

Abrasive Blast Cleaning Machine, End Draft Type Paint Spray Booth

Suction Blaster Machine

Get Price Quote

Suction Blaster Machine, airless shot blasting machine, Brown Aluminum Oxides