Internal Pipe Cleaning Equipment

48,000 Per Piece

1 Piece (MOQ)

Internal Pipe Cleaning Tool

45,000 Per Piece

20 Piece (MOQ)

Best Deals from Cleaning Machine

Sand Blaster Vibrator

Get Price Quote

5 Piece (MOQ)

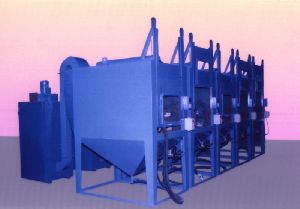

Pneumatic Mould Cleaning Machine

Get Price Quote

Machine consists of : Blast cabinet with main job entry/exit door Rubber lining inside the blast cabinet & on door Illumination inside the blast cabinet. Track mounted work car with rotating turn table. Work is provided with winching arrangement for to & fro motion. Turn table is equipped tilting arrangement, provided with manual hydraulic mechanism. Suction blast nozzles with manual horizontal reciprocation mechanism. Cyclone separator with blast generator Pulse jet type of dust collector. Working Principle : Moulds to be blasted are placed on the rotating turn table and taken inside the blast cabinet for blasting purpose. after taking the work car inside the blast cabinet door of the machine is closed manually. shot blasting operation is started, blast nozzles fire abrasive gently on the mould, placed on the turn table. mould rotates and its own axis, to ensure the 100% exposure to the blast stream. operator manually tilts the turn table from outside the blast cabinet, by manual hydraulic mechanism, so that blasting can be done on the inner corner of the mould. at the same time, if required operator can manipulate the nozzle direction, using manual horizontal reciprocation system, for covering the un-blasted area of the mould. at the same time, cyclone separator, vacuums the fired media from the bottom of the cabinet hopper and after required cleaning transfer the usable media to the blast generator. dust produced during the blasting operation is carried out by the dust collector.

Internal Pipe Cleaning Tool/Roto Blast Tool

50,000 - 70,000 Per Piece

1 Piece(s) (MOQ)

Balaji Tyre Mould Cleaning Machine

1,500,000 Per piece

1 piece (MOQ)

suction blaster

150,000 - 405,000 Per Piece

1 Piece (MOQ)

Cookware Blast Cleaning Machine

Get Price Quote

Generally, cookware is blast cleaned prior to Teflon coating. It removes oxide layer from the surface as well as it imparts surface roughness to facilitate proper adhesion of Teflon coating. SYNCO has developed a blast-cleaning machine for this purpose, wherein the operator places the job on satellite between two fixture plates. The fixture plate shall prevent the job from flying off from blasting station and only exposes the surfaces, which are to be blast cleaned. The indexing turntable carries it into blast chamber where satellite starts rotating the blast station. As job rotates blast guns blast clean the job. After completion of certain nos. of indexes [index counter is provided for this purpose] machine shall stop automatically for preset time and shall restart again. Only loading and unloading of the job is carried out by operator, rest all operations are automatic.

Suction Air Blasting Machine

Get Price Quote

Super Blaster Machine works on suction principle of lifting abrasive media to the blasting gun. High pressure compressed air when injected through venturi creates suction on the side of air injection. This suction pressure so created is used to lift abrasives which mix with the high velocity compressed air creating soft blasting. These super blaster machines are used for glass bead blasting, alumina blasting of soft metals like aluminum di-casting, carving on glasses, roughening of stones. Various standard and special size machines are available for selection. Suction Blaster Operating Principal Suction Blaster is the simplest and most effective way to remove corrosion and old paint. Suction Blaster is a clean, dust free sand blaster that leaves the surface cleaned and well prepared for painting, filling etc. When the cabinet and power module is correctly set-up, the cabinet is ready for operation by actuation of the foot pedal. After pressing the foot pedal air flows through the blast gun. Air moving through the gun draws media into the blast gun mixing chamber. The media mixes with the air and is propelled out the nozzle. After striking the object being blasted, the blast media, along with fines, dust, and byproducts generated by blasting, fall through the grate into the cabinet hopper. These particles are drawn into the reclaimer for separation. Dust and fines are first separated from the reusable blast media. Next the media is screened of oversize particles, and returned to the reclaimer hopper for reuse. Dust and fines are drawn from the reclaimer into the dust collector which traps the dust, discharging clean air. When the foot pedal is released the blasting stops.

Structure Cleaning Shot Blasting Machine

Get Price Quote

1 Piece (MOQ)

Suction Blaster Machine

1,250,000 Per Piece

Abrasive blast cleaning machines

Get Price Quote

Floor Polishing Machines

Get Price Quote

Heavy weight for higher productivity, stability and durability, Thick sheet body for strength and long life, Heavy duty steel coupling for long life operations, Voltmeter I Ampere meter for convenient operations, Heavy duty electric motor of 3.8 HP(Special Design) for high performance and productivity, Inbuilt water tank for continuous water supply for higher productivity and better result, Heavy abrasive holding plate for higher productivity, stability and best result.

Tyre Mould Cleaning Machine

Get Price Quote

1 Piece (MOQ)

Features High in strength Easy to clean Long service life Aerowheel ensures its clients whether in India or abroad timely and efficient delivery of Tyre Mould Blast Cleaning Machine. We have an expert staff with rich and varied experience of more than 25 years who have served the blasting equipment industry with their heart and soul. These professionals will take care of your machine and your requirements most effectively. Besides assurance of quality and competence, we offer you Tyre Mould Blasting Machines that are fully compatible with your requirements. You can tailor your machine as per your specifications with our expert staff. Also Aerowheel is a single destination for all your requirements throughout the optimum life of the machine. We have in our stock a range of additional spare parts and accessories with special services at your services to bring your machine back to its routine function and it enhances the cost of the machine.

Vacuum Cleaner

16,999 Per Piece

Ultrasonic Therapy Machine

3,000 Per Piece

1 Piece(s) (MOQ)

Bar Cleaning Machine, Tube Cleaning Machine

Get Price Quote

We offer Bar Cleaning Machine and Tube Cleaning Machine. The machine is engineered for inline cleaning of external surface of metallic pipes and rods to reputed customers. The machine is simple to operate with minimum maintenance and operator has to simply load and unload the rods/pipes on rotating rollers. the abrasive media generally used is steel shots / c.i. Grit of 25 mesh. The external surface of metallic especially m.s. Pipes / rods are required to be blast cleaned to remove rust and corrosion. the machine is highly productive and featured with roller arrangement, 2 # high speed blasting nozzles, abrasive recovery and cleaning system, dry dust collection unit and control panel. the machine is suited for continuous working. The pipes / rods are placed on motorized roller arrangement, which moves the rods / pipes forward as well as rotates inside the blast chamber. The rods / pipes are exposed to the abrasive blast stream through the twin blat nozzle assembly for blast cleaning. The dust created during blasting is separated & collected in fabric bag dust collector and clean air is discharged to atmosphere keeping the environment clean and eco-friendly. features: mec shot has designed an automatic blasting machine for external cleaning of metallic rods/pipes featured with roller arrangement for job rotation and linear movement. the external surfaces of rods / bars / tubes are cleaned to remove rust / corrosion etc. As a part of surface preparation before subsequent treatment.

Surgical Equipments Cleaning Machine

Get Price Quote

krishna engineers develop medical and surgical tools industry there is requirement for cleaning parts with abrasives to achieve desired anti glare matte finish.

Surgical Equipments Cleaning Machine

Get Price Quote

In medical and surgical tools industry there is requirement for cleaning parts with abrasives to achieve desired / anti glare / matte finish.Finishing of Tweezers, Cleaning of Dental Braces, Finishing of critical metal for joints like hip, knee, elbow, shoulders etc., finishing of critical equipments for cosmetic purpose, Glare free finishing of surgical and hospital instruments, Deburring of hypodermic neddles are some of the application we can assist you with.

floor polish machine

18,000 - 18,500 Per Piece

suction blaster

Get Price Quote

We are offering suction blaster. The suction blaster is work on induction-suction principle of abrasive delivery. It is mainly useful for fine and medium matte finish on soft and plastic material in wide range of heat treatment shops, too, die and mould makers and shot peening of light metal components etc.

Plate Cleaning Machine

Get Price Quote

plate cleaning machine plate cleaning shot blasting machine consist of multiple centrifugal blast wheels each of them driven by individual motors to give a through cleaning. The jobs kept on suitable conveying system with variable speed flexibility. The jobs enters the blast cabinet for cleaning from abrasives fired by multiwheels for homogenous finish. The duly shot blasted components come out from the exit of cabinet. These machines are fully equipped with abrasive recovery and cleaning system, dust collector, control panel and manganese lining. plate cleaning machine the blast cabinet is lined with high manganese tiles in overlap style for ease of replacement. The perforated high manganese casted sheet is placed above screw conveyor line for protection purpose. Multiple shot blast rubber curtains are provided in the inlet and outlet vestibules to stop escaping abrasives. The roller inside blast cabinet is lined with replaceable high manganese steel. the service door is provided in blast cabinet with safety features. The sensor is provided at vestibules for starting blast cycle, when the job is in blast cabinet to avoid unnecessary blasting of job. Blast wheel 4 nos. / 6 nos. Are fitted on blast cabinet to cover shot blasting of end faces of fabricated components. A suitable capacity elevator is provided for transferring shots to rotary screen separator. The rotary screen separator cleans the abrasives and remove oversize as well as dust particles and only required size of shots are fed to blasting wheels. all blast wheel stations are provided with enclosed type shot valve for regulating quantum of shots to the blast wheel unit. A dust collector of reverse pulse jet style is designed and provided for continuous heavy duty operation. The function of dust collector is to keep blast cabinet ventilated and also remove dust particles and small size of shots from abrasive. The operation of entire machine is sequentially programmed by plc mounted in control panel. The plc shows working status of machine, no. Of hours machine run for maintenance requirement and various trouble shooting requirement. Plc programme can be made as per customer’s requirement. the machine is suitable for shot blast cleaning of pre fabricated components for building & automobile structure etc. It is capable of imparting surface finish sa 2.5 & sa-3. The machine can be integrated with painting line as per customer’s requirement. The loading and unloading system for job can also be provided to suit customer’s requirement. the blast wheel is provided which is coupled with blast motor through bearing housing. The blast wheel is precision balanced and hardened for 55 hrc by special hardening process. Hard blasting blades (8 nos.) are provided with hi moly., hi chrome composition giving longer life. The control cage impellers are also made of hi moly, hi chrome. All liners are hi manganese quality for longer life.

Floor Cleaner

30 Per Bottle

Internal Pipe Cleaning Blasting Machine

Get Price Quote

SUCTION BLAST CABINET MACHINE

Get Price Quote

The suction blaster is working on INDUCTION-SUCTION principle of abrasive delivery. It is mainly useful for fine and medium matte finish on soft and plastic material in wide range of heat treatment shops, tool, die and mould makers and shot peening of light metal components etc.

suction blast machines

Get Price Quote

suction blast machines, Sand Shot Blasting Hose, abrasive media

floor polishing pads

Get Price Quote

Floor Polishing Pads are specially designed for marble polishing can be used on engineering stones. Attach them to the floor polisher (three pieces recommended) and supply enough water to get the best results. It is also known as water guard holder, mud guard, flesh guard for marble polishing.

Plate Cleaning Machine

Get Price Quote

Plate Cleaning Machine, Needle Cleaning Machine, Stainless Steel Flat

Abrasive Blast Cleaning Machine

Get Price Quote

We are offering best Abrasive Blast Cleaning Machine

Vacuum Cleaner

Get Price Quote

We are offering latest products of Vacuum Cleaner for all age man & woman.