Steel Grinding Balls

120 Per Kilogram

200 Kilogram (MOQ)

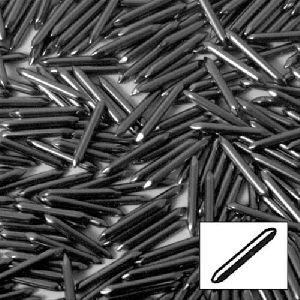

Stainless Steel Media for Burnishing

Get Price Quote

APX Stainless Steel Media - Ball, Satellite, Pin are used for high performance burnishing and polishing.Made up of high grade steel to sustain long uses and impactful applications and available in various sizes for different workpieces and processes.Highly suitable for use with our ball burnishers and vibrators for a smooth and lasting high lustre shine.

Best Deals from Grinding Steel Balls

hyper steel grinding media balls

70 Per Kilogram

5000 Kilogram (MOQ)

Grinding Steel Balls

Get Price Quote

Here the hardened balls are ground to improve suface finish and geometrical parameters. Several careful grinding processes with ceramic wheels lead to a higher size precision preparing the balls for the next final lapping operation.

Hi Chrome Steel Grinding Media Ball

85,000 Per Metric Ton

5 Metric Ton (MOQ)

Forged Steel Grinding Media Balls

Get Price Quote

Forged Steel Grinding Media Balls Item Code: IS12658-1989 We have on offer for our customers a vast range of Forged Grinding Media Balls in various sizes and technical specifications. Steel, carbon, manganese, phosphorus, silicon, sulfur, chromium and others are utilized in the manufacturing process of these types of grinding media balls. Extensively utilized in grinding and milling applications, these products have helped us garner a rich clientele in the market. Specifications: Balls diameter (mm): 125,100, 90, 80, 75, 70, 65, 60, 50 ,40, 30, 25 & 20 Cylpebs (mm): 25x25, 22x22, 19x19 Balls diameter (mm): 125, 100, 90, 80, 75, 70, 65, 60, 50, 40, 30, 25, & 20 Cylpebs (mm): 25x25, 22x22, 19x19 Forged Steel Grinding Media Balls as per IS 12658:1989

grinding media steel balls

140 Per Kilogram

Hi-chrome Steel Grinding Media Balls

Get Price Quote

Ultimo Engineers is leading Manufacturer, Exporter & Supplier of Hi-Chrome Steel Grinding Media Balls. These Hi-Chrome Steel Grinding Media Balls are widely used across the industry for numerous milling and grinding applications. Ball mills and Pulverizers are a few examples where Hi-Chrome Steel Grinding Media Balls are regularly used. Advantages Suitable for applications where resistance to wear and chemicals is needed Ensures effective grinding and mixing Grinding process is contamination free and fast Can be hardened according to customer requirements for use in cases where impact grinding is required Applications Food Processing industry Mining And Oil industry Cosmetic industry Pharmaceutical industry Metal Processing industry Different Grades Available Impact & Wear Resistant High Mn. Steels, lS : 27 6. Wear Resistant Steels. IS : 4 771 Plain Carbon Steels, IS : 1030,2707. Abrasion Resistani Steels. IS : 4896. Heat Resistant S teels,lS :4522. Stainless Steels, AISI : 304, 316 Grades. Ceramic Porcelain Balls 2mm to 90mm Ceramic Steatite Balls 2mm to 90mm Ceramic High Aluminus Balls 2mm to 80mm

Grinding Steel Balls

110 - 120 Per kgs

1 Ton (MOQ)

All Sizes of Grinding steel balls are available on competitive prices.

Hyper Steel Grinding Balls

Get Price Quote

Stainless Steel Grinding Media Ball

300 Per Kilogram

hyper steel grinding media balls

Get Price Quote

Steel Grinding Media Balls

300 - 500 Per Kilogram

1000 Kilogram (MOQ)

hyper steel grinding media balls

Get Price Quote

Melting and Moulding Shop Medium Frequency Dual Track Induction Furnace, fully automatic Sand Moulding Plant with 4 nos. of Jolt Squeeze type Moulding Machine and Overhead Cranes. Heat Treatment Shop Fully automatic continuous pusher type heat treatment plant with temperature graph attachment for Hi Chrome & Hyper steel grinding media balls and liner with oil and Air quenching arrangement & fully automatic 2 nos. of batch type furnace with water quenching arrangement for manganese steel castings.

chrome steel grinding media ball

Get Price Quote

Our products are used in various manufacturing industries like pellet, steel, cement, thermal power etc.

Steel Grinding Balls

Get Price Quote

hyper steel grinding media balls

Get Price Quote

Hyper steel Grinding Media Balls and Cylpebs as per IS 6079-1980 (a) CHEMICAL COMPOSITION: The chemical composition of the grinding media will be as per IS 6079-1980: as follows: GRADE-1 (For size 60 mm & above) GRADE-2 (For size below 60 mm) Carbon 1.10-1.60 1.50-2.00 Silicon 1.00 Max. 1.00 Max. Manganese 0.90-1.60 0.90-1.60 Chromium 1.20-2.40 1.20-2.40 Sulphur 0.06 Max. 0.06 Max. Phosphorous 0.06 Max. 0.06 Max. (b) HARDNESS: When tested in accordance with IS 15001983 the hardness at any point across the section of the ball is more than 375 BHN. (c) MICROSTRUCTURE: Microstructure shall be free from continuous carbide network. (d) HEAT TREATMENT: The grinding media is suitably heat treated to obtain the required hardness and Microstructure.

Steel Grinding Balls

Get Price Quote

We are actively engaged in offering Steel Grinding Balls to the clients. The Steel Grinding Balls are manufactured using Cold forging (Heading) and Hot forging process. Checked on different parameters, the Steel Grinding Balls are appreciated for their excellent finish and long lasting durability. The Steel Grinding Balls are widely used in process equipment such as Ball Mills, Conical Ball Mills, Attritor and Dispersion Mills, for the reduction in particles size by Grinding / Milling operation.

Steel Grinding Balls

70 Per Kilogram

hyper steel grinding media balls

Get Price Quote

As per the variegated application requirements of clients, they can avail from us a quality range of Hyper steel grinding Media Balls and Cylpebs in various diameters and technical specifications. These grinding media balls and cyplebs are widely utilized in grinding and milling applications. Specifications: Chemical composition: The chemical composition of the grinding media is in accordance with IS 6079-1989 Hardness: When tested in accordance with IS 1500/1983, the hardness is found to be more than 375 BHN Microstructure: Microstructure is free from continuous carbide network Heat treatment: The grinding media is heat treated to obtain the required hardness and microstructure Balls diameter (mm) – 125, 100, 90, 80, 75, 70, 65, 60, 50, 40, 30, 25, 20, 17, 15 Cylpebs (mm) – 35 x 35, 25×25, 22×22, 19×19 Hardness: When tested in accordance with IS 1500/1983 the hardness at any point across the section of the ball is more than 375 BHN. Microstructure: Microstructure shall be free from continuous carbide network. Heat treatment: The grinding media is suitably heat treated to obtain the required hardness and Microstructure. Standard size of grinding media: Balls diameter (mm)-125, 100, 90, 80, 75, 70, 65, 60, 50, 40, 30, 25, 20, 17, 15 Cylpebs (mm)-35 x 35, 25×25, 22×22, 19×19