Vibro Feeder Machine

2,050,000 Per Set

1 Set (MOQ)

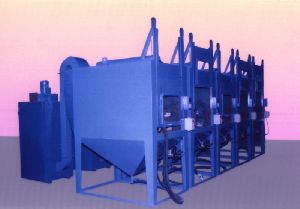

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

Best Deals from Industrial Machine

Abrasive Blasting Machine

125,000 Per Piece

Cabinet type abrasive blasting machine we are manufacturer of all types of abrasive blasting machines.

portable sand blasting machines

30,000 Per Piece

1 Piece(s) (MOQ)

ABRABLAST PORTABLE SAND BLASTING MACHINE AB-P7-1001R AB-P7-501R AB-P7-301R AB-P7-150 With safety wear

Rotary Barrel Type Shot Blasting Machine

300,000 - 600,000 Per Set

valve bag filling machine

270,000 Per piece

1 piece (MOQ)

Valave bag , wheat seeds bag filling , Flour bag filling machine

Rotary Indexing Machines

Get Price Quote

Mec shot has recently designed manufactured, installed & commissioned airless blasting machines with rotary indexing hanger for surface preparation of aluminum dye casted automobile engines parts.

Rotary Indexing Satellite Table Machine

Get Price Quote

The essential component of our Rotary Indexing Satellite Table Machine is the indexing mechanism that rotates the work piece through fixed positions within the blasting machine. It consists of various small symmetrical parts such as gears, engine disks, shafts, bomb shells, brakes and clutch disks. Our Rotary Indexing Satellite Table Machine is specifically designed for use in automotive, aerospace industries & defense industries. It can be combined with robots for automatic loading and unloading, thereby, creating fully integrated manufacturing cells.

Abrasive blast cleaning machines

Get Price Quote

suction blaster

Get Price Quote

We are offering suction blaster. The suction blaster is work on induction-suction principle of abrasive delivery. It is mainly useful for fine and medium matte finish on soft and plastic material in wide range of heat treatment shops, too, die and mould makers and shot peening of light metal components etc.

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving

portable abrasive blaster

Get Price Quote

Portable Abrasive Blaster The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving,

suction blaster

Get Price Quote

Suction Blaster is the simplest and most effective way to remove corrosion and old paint. Suction Blaster is a clean, dust free sand blaster that leaves the surface cleaned and well prepared for painting, filling etc. When the cabinet and power module are correctly set-up, the cabinet is ready for operation by actuation of the foot pedal. Fully depressing the foot pedal causes air to flow through the blast gun. Air moving through the gun draws media into the blast gun mixing chamber. The media mixes with the air and is propelled out the nozzle. After striking the object being blasted, the blast media, along with fines, dust, and byproducts generated by blasting, fall through the grate into the cabinet hopper. These particles are drawn into the reclaimer for separation. Dust and fines are first separated from the reusable blast media. Next the media is screened of oversize particles, and returned to the reclaimer hopper for reuse. Dust and fines are drawn from the reclaimer into the dust collector which traps the dust, discharging clean air. When the foot pedal is released the blasting stops.

portable abrasive blasting machine

Get Price Quote

This is small abrasive portable blaster. This is required for repairing & maintenance purpose. In this system Abrasive storage capacity is up to 42 liters. In this model we use 5 mm tungsten carbide Nozzle & Blasting hose of 19 mm. Cleaning Rate of this model is Approx 3 – 4 Sq. meter.

pressure blasting machine

Get Price Quote

offers an environment friendly cabinet type abrasive blasting machine for generating anchor pattern on components that can be handled in a cabinet enclosure and operator maneuver the blasting nozzle from hand holes provided at the front of cabinet. To view the blasting operation, a vision window is provided at front side. Works on Injection Suction principle of blasting. Uses the venturi principle to draw abrasive from a non-pressurized hopper to the blast gun where it is combined with the compressed air stream and propelled against the work surface. Suction blast machines are most easily distinguished by having two hoses (one for air and one for abrasive) running to the blast gun. Works on Injection Suction principle of blasting. Uses a slurry pump to draw the wet slurry of very fine abrasive and water to the blast gun where it is combined with the compressed air stream and propelled against the work surface

guar gum machinery

Get Price Quote

Please follow the link of our Group companies: SHREE VIJAYLAXMI INDUSTRIES - (India largest Manufacturer & Exporter of Guar Gum Equipments)Please follow the link of our Group companies: SHREE VIJAYLAXMI INDUSTRIES - (India largest Manufacturer & Exporter of Guar Gum Equipments)

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include deburring, descaling, peening, polishing, stress relieving

suction blaster

Get Price Quote

1 Piece (MOQ)

manual sand blasting machine

Get Price Quote

1 Piece (MOQ)

pressure blasting machine for drum and cylinder

Get Price Quote

pressure blasting machine for drum & cylinders