screw feeder machine

125,000 - 150,000 Per Set

1 Piece (MOQ)

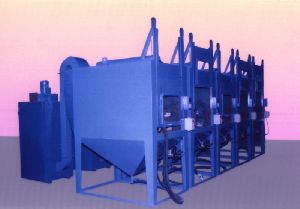

Sand Blasting Machine

Get Price Quote

Surface International offers an economical range of Sand Blasting Machine that consist of special attributes such as Sturdy Construction, Exquisite quality, and Low consumption of energy.

Best Deals from Industrial Machine

240 V Sand Blasting Machine

70,000 Per piece

1 piece (MOQ)

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

PLC Based Rotary Bag Packing Machine

400,000 Per Set

1 Set (MOQ)

Abrasive Blasting Machine

125,000 Per Piece

Cabinet type abrasive blasting machine we are manufacturer of all types of abrasive blasting machines.

WASHING MACHINE

Get Price Quote

Being a quality conscious firm, we conduct strict quality checks for ensuring the product quality. We have developed the entire in-house unit wherein we keep our raw material to fulfill variegated requirements of the buyers. Also, we make sure that the material is sourced from the reliable places only.

pressure blasting machine

Get Price Quote

Rotary Shotcrete Machine

Get Price Quote

The machine works on a dry mix principle. The material is duly filled into the feeding hopper from where it falls into the chamber of revolving rotor. The mix is then transported in a continuous process to the air chamber; from there it is blown by the compressed air stream through the hose to the spraying nozzle, and to the application area respectively. Water is added to the dry concrete in the nozzle at the end of the conveying hose pipe. The machine is driven by electric motor.

BU vacuum blasting machine

Get Price Quote

1 Piece (MOQ)

Rotary Barrel Type Shot Blasting Machine

Get Price Quote

abrasive blast equipment

Get Price Quote

abrasive blast equipment, shot peening equipment

Abrasive blast cleaning machines

Get Price Quote

Rotary Barrel Type Shot Blasting Machine

300,000 - 600,000 Per Set

Rotary Indexing Machines

Get Price Quote

Mec shot has recently designed manufactured, installed & commissioned airless blasting machines with rotary indexing hanger for surface preparation of aluminum dye casted automobile engines parts.

Guar Gum Powder Plant Machinery

Get Price Quote

We are pleased to introduce ourselves as leading manufacturer and exporter of guar gum from india, we are having vast experience in this field. As we are more then 21 years old in this market. we are manufacturing guar gum splits , guar gum powder and in producing this we always do new experiments on machines to do some good things in quality and quantity , and we have great pleasure to say that by this way we become master in making guar gum machines.

valve bag filling machine

270,000 Per piece

1 piece (MOQ)

Valave bag , wheat seeds bag filling , Flour bag filling machine

portable abrasive blasting machine

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving, Deflashing and cleaning.Portable abrasive blaster pressure feeds the system of abrasive propelling and results in higher production rates. The pressure vessels are tested to 250 psig and coded. Blast nozzles special design and tungsten carbides lined, result in long service life. It is equipped with high static and low weight blast hose. The remote control ON OFF is in operators' hand and requires no electric connection.

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving

guar gum machinery

Get Price Quote

Please follow the link of our Group companies: SHREE VIJAYLAXMI INDUSTRIES - (India largest Manufacturer & Exporter of Guar Gum Equipments)Please follow the link of our Group companies: SHREE VIJAYLAXMI INDUSTRIES - (India largest Manufacturer & Exporter of Guar Gum Equipments)

suction blaster

Get Price Quote

Suction Blaster is the simplest and most effective way to remove corrosion and old paint. Suction Blaster is a clean, dust free sand blaster that leaves the surface cleaned and well prepared for painting, filling etc. When the cabinet and power module are correctly set-up, the cabinet is ready for operation by actuation of the foot pedal. Fully depressing the foot pedal causes air to flow through the blast gun. Air moving through the gun draws media into the blast gun mixing chamber. The media mixes with the air and is propelled out the nozzle. After striking the object being blasted, the blast media, along with fines, dust, and byproducts generated by blasting, fall through the grate into the cabinet hopper. These particles are drawn into the reclaimer for separation. Dust and fines are first separated from the reusable blast media. Next the media is screened of oversize particles, and returned to the reclaimer hopper for reuse. Dust and fines are drawn from the reclaimer into the dust collector which traps the dust, discharging clean air. When the foot pedal is released the blasting stops.

portable abrasive blasting machine

Get Price Quote

This is small abrasive portable blaster. This is required for repairing & maintenance purpose. In this system Abrasive storage capacity is up to 42 liters. In this model we use 5 mm tungsten carbide Nozzle & Blasting hose of 19 mm. Cleaning Rate of this model is Approx 3 – 4 Sq. meter.

suction blaster

Get Price Quote

We are offering suction blaster. The suction blaster is work on induction-suction principle of abrasive delivery. It is mainly useful for fine and medium matte finish on soft and plastic material in wide range of heat treatment shops, too, die and mould makers and shot peening of light metal components etc.

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include deburring, descaling, peening, polishing, stress relieving

Rotary Barrel Type Shot Blasting Machine

Get Price Quote

Rotary Barrel Type Shot Blasting Machine, Portable Sand Blasting Machine

pressure blasting machine

Get Price Quote

offers an environment friendly cabinet type abrasive blasting machine for generating anchor pattern on components that can be handled in a cabinet enclosure and operator maneuver the blasting nozzle from hand holes provided at the front of cabinet. To view the blasting operation, a vision window is provided at front side. Works on Injection Suction principle of blasting. Uses the venturi principle to draw abrasive from a non-pressurized hopper to the blast gun where it is combined with the compressed air stream and propelled against the work surface. Suction blast machines are most easily distinguished by having two hoses (one for air and one for abrasive) running to the blast gun. Works on Injection Suction principle of blasting. Uses a slurry pump to draw the wet slurry of very fine abrasive and water to the blast gun where it is combined with the compressed air stream and propelled against the work surface

Rotary Barrel Machine

350,000 Per Set

1 Set(s) (MOQ)

This machine is probably the smallest in the family of Airless Machines, and miniature version of Tumblast Machine (power consumption is very low 5 HP only). Specially designed for cleaning of Small/Medium size Iron, Steel, Alloy, and Non-Ferrous Casting, Forging, Heat treated Parts etc. Hence it is ideal for foundries, forging unit and small job shops where less space is required and economic production is concerned. The Machine has rotatory barrel type (Size: 649 mm Dia x 625 mm Length) with thick perforated rubber sheet. The door is opened and components are fed into the machine. The barrels rotate at low rpm and tumbling action, which also ensures the safety of the components. The powerful Blast wheel fires shots on the components and uniform blasting is done. The machine is controlled by control panel and electronic timer. Also, abrasive Recollection System along with Dust Collector (dry type) is also provided as standard fitment.

Abrasive Blasting Machine

Get Price Quote

Abrasive Blasting Machine, Shot Blasting Machine

Rotary Barrel Peening Machine

Get Price Quote

Rotary Barrel Peening Machine, Indexing Shot Blasting Peening Machine

Abrasive Blast Cleaning Machine

Get Price Quote

We are offering best Abrasive Blast Cleaning Machine