Sand Blasting Machine

Get Price Quote

industrial flour mill machine

Get Price Quote

Best Deals from Industrial Machine

Portable Sand Blasting Machine

Get Price Quote

Belt Feeder Machine

1,075,000 Per Piece

1 Piece (MOQ)

pressure blaster machine

Get Price Quote

Pressure blaster works on the direct pressure principle of blasting. The pressure blaster produces high abrasive velocity which results in completing the job at a faster rate. A pressure vessel, directly bolted below a hopper of a cabinet, has automatic abrasive refilling arrangement. A tubular fabric bag dust collector, with generous filter area is attached with the cabinet as standard feature for high efficiency of dust collection. A manual shaker is also provided for rigorous shaking. The pressure blaster is recommended for fast cleaning, removal of heavy rust and corrosion using coarse abrasives. It is most suitable for etching the surface needed for rubber lining, FRP lining and metal spraying. Castings and forgings are cleaned speedily. Blast pressure can be controlled from 30 to 90 psig. Almost all types of coarse and medium sized abrasives can be used depending on the application.

Rotary Indexing Machines

Get Price Quote

Mec shot has recently designed manufactured, installed & commissioned airless blasting machines with rotary indexing hanger for surface preparation of aluminum dye casted automobile engines parts.

Pressure Air Blasting Machine

Get Price Quote

This surface pressure blaster is from the family air operated shot blasting machine and is suitable for units with moderate output. The abrasive stream is propelled with high velocity air current creating abrasion on the components. The components can be exposed to the blast stream by maneuvering it under the blasting Stream. If the components are bigger they can be kept on the floor of the blast cabinet or on a rotary table provided as optional accessory. Other optional accessories are motorized tum blast basket & rotary table with mounted track extension. This machine is a manually handled air operated machine. In this machine component is placed in-side the cabinet. One nozzle is provided for blasting purpose; operator put its hand in the Hand gloves section and used the gun/nozzle to blast clean the component. In this system track extension system along with manual turn table can also be incorporated

Abrasive Blasting Machine

125,000 Per Piece

Cabinet type abrasive blasting machine we are manufacturer of all types of abrasive blasting machines.

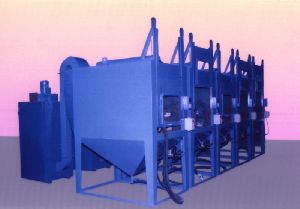

Abrasive blast cleaning machines

Get Price Quote

valve bag filling machine

270,000 Per piece

1 piece (MOQ)

Valave bag , wheat seeds bag filling , Flour bag filling machine

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

Rotary Barrel Type Shot Blasting Machine

300,000 - 600,000 Per Set

portable abrasive blaster

Get Price Quote

Portable Abrasive Blaster The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving,

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include Deburring, descaling, peening, polishing, stress relieving

Paper Napkin Making Machine

Get Price Quote

Paper Napkin Making Machine, Hydraulic Pump, hydraulic spare parts, Tractor

portable abrasive blasting machine

Get Price Quote

This is small abrasive portable blaster. This is required for repairing & maintenance purpose. In this system Abrasive storage capacity is up to 42 liters. In this model we use 5 mm tungsten carbide Nozzle & Blasting hose of 19 mm. Cleaning Rate of this model is Approx 3 – 4 Sq. meter.

portable abrasive blaster

Get Price Quote

The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. The operation is performed on metals, glass, ceramics, plastic and stone.The machine works on pressure blasting principle, consist of a blast generator. The abrasives are filled at the top of machine when machine is not working and blast generator is not pressurized. At the top, a vibrating sieve is provided to sieve the abrasive filled. The oversize abrasive and debris are retained on the screen, thus prevent the choking of blast line. When mushroom valve is opened the abrasive will get transferred to blast generator for blasting. The mushroom valve gets closed when compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. The Blast Generator is fabricated from MS Steel plate of thickness not less than 6 mm as per IS-2825 and hydraulically tested for 250 psi.

guar gum machinery

Get Price Quote

Please follow the link of our Group companies: SHREE VIJAYLAXMI INDUSTRIES - (India largest Manufacturer & Exporter of Guar Gum Equipments)Please follow the link of our Group companies: SHREE VIJAYLAXMI INDUSTRIES - (India largest Manufacturer & Exporter of Guar Gum Equipments)

suction blaster

Get Price Quote

We are offering suction blaster. The suction blaster is work on induction-suction principle of abrasive delivery. It is mainly useful for fine and medium matte finish on soft and plastic material in wide range of heat treatment shops, too, die and mould makers and shot peening of light metal components etc.

pressure blasting machine

Get Price Quote

offers an environment friendly cabinet type abrasive blasting machine for generating anchor pattern on components that can be handled in a cabinet enclosure and operator maneuver the blasting nozzle from hand holes provided at the front of cabinet. To view the blasting operation, a vision window is provided at front side. Works on Injection Suction principle of blasting. Uses the venturi principle to draw abrasive from a non-pressurized hopper to the blast gun where it is combined with the compressed air stream and propelled against the work surface. Suction blast machines are most easily distinguished by having two hoses (one for air and one for abrasive) running to the blast gun. Works on Injection Suction principle of blasting. Uses a slurry pump to draw the wet slurry of very fine abrasive and water to the blast gun where it is combined with the compressed air stream and propelled against the work surface

portable abrasive blaster

Get Price Quote

The abrasive blasting as a finishing process has been successfully utilized on metal, glass, and ceramics, plastic and stone. Its functions include deburring, descaling, peening, polishing, stress relieving

Industrial Airless Shot Blasting Machine

Get Price Quote

Industrial Airless Shot Blasting Machine, Aluminium Oxide, DF Grit

Abrasive Blasting Machine

Get Price Quote

Abrasive Blasting Machine

Abrasive Blast Cleaning Machine

Get Price Quote

We are offering best Abrasive Blast Cleaning Machine

Gypsum Board Machine

Get Price Quote

Gypsum Board Machine, Reversible Concrete Mixer

portable sand blasting machines

Get Price Quote

portable sand blasting machines, Sand Blasting Machine

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, HVOF Thermal Spray Gun, plasma spray system

Air Bubble Machine

Get Price Quote

Air Bubble Machine

Sand Blasting Machine

Get Price Quote

Sand Blasting Machine, sand blasters, Sand Blasting Machine

Sand Blasting Machine

Get Price Quote

Sand Blasting Machine, GARNET ABRASIVE MEDIA, Shot blasting media