Wire Flame Spray

Wire Flame Spray uses a single wire that is fed into a jet flame. The temperature is close to 10,000 K, melting the wire. The air stream from the jet atomizes the molten particles, propelling them onto the substrate. The technological parameters, such as feedstock, flame spray gas composition and flow rate, and energy input, play a large role in the relationship between the particles and the substrate. Extension (Coating on internal dia.) Length : 6” / 12” / 24” / 36”Technical Advantages: Less oxides Coatings can be easier to machine due to reduced oxide Economic Advantages: Higher deposit efficiency with low melting point materials such as aluminum and zinc Lower initial equipment cost Operational Advantages: Non-conductive wires can be sprayed Less fine dust created when spraying makes overspray less flammable or explosive More portable for on-site spraying Simple to ignite Easy to operate High spray rate with low gas consumption Low maintenance design reduces operating costs Can be used with both hard and soft wires Extension modules for internal bore applications

...more

WIRE COMBUSTION SPRAY

Lead Time : 3 DAYS

Place of Origin : Rajasthan, India

Warranty : 1 Year

Condition : New

Color : GOLDEN

...more

WIRE ARC SPRAY SYSTEM

1. SPRAY GUN2. POWER SOURCE3. SPOOL STAND 4. GUN STAND5. HOSES & CABLE6. SAFETY EQUIPMENTSOPTIONAL ITEMS :-1. EXTENSION NOZZLE FOR INTERNAL SPRAY

...more

Wire Arc Spray Equipment

Color : Grey

Warranty : 1 Year

Condition : New

Voltage : 220-460V

Weight : 250

...more

Wire Arc Spray

1. SPRAY GUN2. POWER SOURCE3. SPOOL STAND 4. GUN STAND5. HOSES & CABLE6. SAFETY EQUIPMENTS OPTIONAL ITEMS :-1. EXTENSION NOZZLE FOR INTERNAL SPRAY

...more

TWIN WIRE ARC SPRAY PUSH TYPE

This twin wire arc spray system is very easy to handle & most suitable for manual as well as machine mounted metal spray coating works. System consists of following articles:- Spray Gun Air Hose & Cables Twin Wire Feeder Power Source Wire Conduit Set Recommended Spares Set Personal Protective Equipment Safety interlocks

...more

TWIN WIRE ARC SPRAY PUSH TYPE

PUSH ARC SPRAY SYSTEM :-This twin wire arc spray system is very easy to handle & most suitable for manual as well as machine mounted metal spray coating works. System consists of following articles:- Spray Gun Air Hose & Cables Twin Wire Feeder Power Source Wire Conduit Set Recommended Spares Set Personal Protective Equipment Safety interlocks

...more

TWIN WIRE ARC SPRAY PUSH TYPE

This twin wire arc spray system is very easy to handle & most suitable for manual as well as machine mounted metal spray coating works. System consists of following articles:- Spray Gun Air Hose & Cables Twin Wire Feeder Power Source Wire Conduit Set Recommended Spares Set Personal Protective Equipment Safety interlocks

...more

TUBE MILL COATING PLANT

Parat Technologies offer complete zinc spray coating plant for tube mill application. ERW tubes after welding loose its anti-corrosion property where welding is done on the seam. We offer twin wire arc spray coating system with complete fabrication unit as turnkey coating project:- Twin Wire Arc Spray Coating System 200/400 ampere with Electric Drive Spray Gun Spray Booth Cyclone Dust Collector Required Ducting Pipes Exhaust Unit Filter Unit – Bag Type/Cartridge Type (Options available)

...more

thermal spray wire

Brand Name : parat

thermal spray spare parts

Parat Technologies supply Thermal Spray Ceramic Rods with standard diameters. These rods are suitable for applying coating with Rokide Rod spray type coating equipment.

...more

Thermal Spray Coating Machine

Coating : Thermal Spray

Brand Name : Parat

Condition : New

...more

Pure Garnet Abrasive

We have variety of Garnet which is naturally available in vast quantities in Southern india, Western india and River Basins. The Garnet we provide is natural, inert, hard and low dust, Recyclable as its basic properties. It is mined from the southern coasts of india and some river basins which is curved and cubical in shape due to the wave action of thousand years. Where as, the rock garnet is made from grinding and crushing of Raw Garnet rocks available in some parts of Rajasthan also having sharp edges suitable for blast cleaning and surface preparation prior to its treatment or painting or coating. Applications• Water jet cutting• Sand blasting/blast cleaning• Denim blasting• Filtration etc

...more

PORTABLE GRIT BLASTING MACHINE

OPERATOR SAFETY WEARS:-• Air Fed Blasting Helmet• Helmet Hose• Helmet Air Conditioner• Air Breather• Gum Boot• Hand Gloves• Operator’s Suit

...more

High Velocity Oxy Fuel

High Velocity Oxy Fuel (HVOF) devices are a subset of flame spray. There are two distinct differences between conventional flame spray and HVOF. HVOF utilizes confined combustion and an extended nozzle to heat and accelerate the powdered coating material. Typical HVOF devices operate at hypersonic gas velocities, i.e. greater than MACH 5. The extreme velocities provide kinetic energy which help produce coatings that are very dense and very well adhered in the as-sprayed condition. BENEFITS :- Low porosity (10000 psi) Uniform repeatability Low operating cost Higher particle velocities Stable deposition rate Controlled coating thickness Safety interlocks

...more

Garnet Sand

Material : garnet

Electric arc spray equipment

Condition : New

Brand Name : Parat

After-Sales Service Provided : Engineers available to service machinery overseas

...more

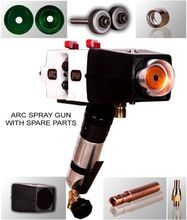

Arc Spray Gun

Warranty : 1 Year

Color : BLACK

Weight : 3.6 kg

...more

Aluminium Arc Spray

Certification : CE ISO9001

Brand Name : Parat

Voltage : 28-36

Supply Ability : 1 Unit/Units per Month

Place of Origin : Rajasthan, India

Warranty : 12 Months

Condition : New

Lead Time : 3 days

Coating : Aluminium Spray Metallizing

...more

Abrasive Grit Media

Flame Spray Coatings

Wire Arc Spray Coatings

hvof coating services

HVOF Coating Service

High Velocity Oxy Fuel (HVOF) devices are a subset of flame spray. There are two distinct differences between conventional flame spray and HVOF. HVOF utilizes confined combustion and an extended nozzle to heat and accelerate the powdered coating material. Typical HVOF devices operate at hypersonic gas velocities, i.e. greater than MACH 5. The extreme velocities provide kinetic energy which help produce coatings that are very dense and very well adhered in the as-sprayed condition.BENEFITS :- Low porosity (10000 psi) Uniform repeatability Low operating cost Higher particle velocities Stable deposition rate Controlled coating thickness Safety interlocks TYPICAL HVOF APPLICATIONS :- Hydro Power – Pelton, Seat, Runner, Francis turbine etc. Thermal Power – Boiler tube, ID Fan, Barrel etc. Aerospace – Landing gear Paper Industry – Rolls General – Shafts, Bearing, Rollers, Rings, Valves – Ball Valve, Gate Valve etc.

Type : HVOF Coating Service

...moreBe first to Rate

Rate This