Orion Poultry Pellet Mill Die

30,000 - 450,000 Per Piece

1 Piece(s) (MOQ)

KBR Pellet Die Set

4,000 - 4,500 Per Nos

1 Set (MOQ)

Best Deals from Pellet Die

Flat Die Pellet Mill

Get Price Quote

100 Piece (MOQ)

Heading Pellet Dies

Get Price Quote

pellet mill dies

Get Price Quote

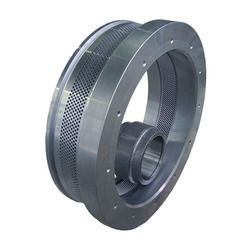

The range of Pellet Mill Dies is installed in mills for better pelleting index which improves the shelf life of the product. Highly accredited in the industry, these are engineered to process a meal, fiber and small granules into pellet. Before final dispatch, these are rigorously checked on parameters of efficiency, performance and robustness. Widely appreciated for their sturdy construction, negligible maintenance and hassle free installation, these are broadly demanded in poultry, livestock, and food and agriculture industry.

Bullet Forming Dies

Get Price Quote

With the help of our experienced team members, we have been able to offer a wide range of Bullet Forming Dies. Engineered under the strict supervision of expert quality controllers, these dies are widely acclaimed for their robust construction, optimum quality, corrosion resistance and optimum performance. Our dies are available in various standard sizes and technical specifications as per the exact requirements of clients.

Pellet die

6,599 Per Piece

pellet mill dies

1,200,000 - 2,500,000 Per Set

1 Set (MOQ)

pilger die

75,000 - 500,000 Per Piece

1 Set(s) (MOQ)

Ambar Steel Industries is the leading Indian supplier of pilger mills Tools, to meet the specific demands of out tube manufacturing customers. Ambar Steel Industries provides custom designed solutions for tube reduction emphasizing cold pilger mills. Pilger mill production can deliver high yields at lower cost compared to drawing processing. Area reductions of greater than 70% are achievable in one reduction with pilger processing of tubes depending on the alloy. This process can also produce tighter tolerances and better surface finish on both outer and inner surfaces. AMABR STEEL INDUSTRIES also provides equipment upgrades of existing pilger mills to increase efficiency and productivity. By replacing old, antiquated, mechanical gearboxes with 21st century technology, and introducing automated feed & turn systems, down time of existing mills can be reduced substantially. With the 18 years of experience of Rajesh Thakor & Teem built into Ambar Steel Industries, we can help improve your tube production return on your INVESTMENTS. We pride ourselves in offering solid engineering solutions to your tube manufacturing process with a commitment to customer satisfaction.

Flat Die Pellet Mill

Get Price Quote

We are offering electric flat die feed pellet machine. introduction flat die feed pellet mill is a compact and simple design of pelletizing press which is welcome in small,medium poultry farm and light industrial or family use. It is powered by electric engine and works vertically. Flat die pellet mill has two working types: one is stationery die with a set of rotating rollers, the other is stationery rollers with rotating die. According to research and experiment, the stationery rollers with rotating die type is the best to make animal feed. flat die feed pellet mill features and application 1.driven by electric motor is more energy-saving and environmentally friendly. 2.both the rollers and the flat die have passed wear-resistant process. The two sides of the flat die are exchangeable, which extends its service life and lowers cost. 3.compact structure,low consumption, convenient to move and easy to clean. 4.visibility. It is possible to view the material during pelletization as the best way to fix problems. 5.multifunctional. Electric flat die pellet mill is largely applicable to rabbit, small livestock farm and rural individual feeding; also applied to produce biological bacterial manure, organic fertilizer and compound fertilizer, etc.

Pellet Press Dies

7,000 - 32,206 Per Piece

Pellet mill Ring Dies

300,000 Per Piece

All kinds of pellet mill dies which suits to all types of pellet mills.we supply ring dies to that company with high quality to competitive price all over the year. We have never compromised on the quality to the customer. We believe in keeping the customers happy and providing them with products at a very competent price.

Wood Pellet Dies

100,000 - 700,000 Per Piece

1 Piece(s) (MOQ)

pellet mill dies

14,000 Per Piece

pellet mill dies

Get Price Quote

Pellet Mill Die are developed using superior quality material and latest technology as per the international standards and norms. These are widely demanded, who manufacture quality feeds for agricultural usage.

Heading Pellet Dies

Get Price Quote

Pellet Making Die

8,000 Per Piece

pellet mill dies

Get Price Quote

After successful launch and acceptance of D-Chrome™ world wide RK has launched a value added product D-CARB. These are the dies used mainly for Cattle feed and for high roughage woodBio-Fuel Pelleting. These dies are available with hole dia 4- 12mm.

pellet mill die

15,000 Per Piece

pellet mill dies

30,000 Per Piece

TC carbide Bullet Forming Dies

Get Price Quote

We are one of the most reputed Bullet Forming Dies for domestic as well as export market. Our carbide Bullet Forming Dies do not deform under high compressive force. The range of Bullet Forming Dies is commonly used in various defense industries. The company is also counted among the most renewed Bullet Forming Dies manufacturers in the business

pellet mill dies

Get Price Quote

Various pelleting application include Poultry Cattle feed Pellets, Organic Fertilizers Pellets Plastic Waste Pellets, Manure Pellets, Gypsum Pellets, Micro Nutrient Pellets, Kaolin Pellets, biomass fuel pellets etc. We offer pellet mills which are capable of producing pellets of diameters ranging from 1mm die to 20mm die.

pellet mill dies

Get Price Quote

PMI Dies Buy superior die to ensure saving in electrical power, more tonnage per hour, sound of pellets less down time of pelleting press. Dies are exclusively manufacture to customer specification production and services are standard though knowledge of raw material and innovative technology are entirely pressed in to service of the client who feels himself fully supported by the first rate technical assistance. Dies are guaranteed to result in trouble free production high quality pellets, Dies are produced in a variety of alloy material and in different grades of alloy steels, It is produced as per specification a good type of materials and hardening process to ensure optimum die life. Have right manufacturing process as with die material PMI has to it's disposal a number of manufacturing process to the customer’s specific application Quality Control: to assure the strictest adherence to quality standard of all die machining, drilling, Heat Treating and polishing operation are conducted in house providing leadership in today's die technology in INDIA

Pellet Ring Die

20,000 Per Piece

pellet mill die

35,000 Per unit

pellet dies

6,599 Per Piece

pilger die

Get Price Quote

The main function of this machine is to grind the groove of pilgar dies which are used in the cold pilgar mills for producing pipes. The machine is so designed that the complete groove will be generated automatically on the die with the specially designed motorized spindle. The machine is designed to The machine is fully automatic with four Axes CNC high end controller which is the top of line controller in the market. This machine is solely designed and manufactured to improve the quality of pipes and tool life in cold pilgar mills. The appropriate use of the machine may reduce the problems faced on the shop floor like tool breakage, reconditioning etc and save costs. The machine can be custom made to handle any sizes of dies ranging from 100mm to 650 mm of diameter and the width of dies from 80 mm to 180 mm. the groove diameter can be from 10 mm to 90 mm. the dies can be reground to a different size after using it on to the mills. Special features of the machine includes motorized spindle, probe for inline measurement and advanced automization to contribute to time and cost savings. This machine has proven to be an import substitute for the Indian market as well as cost effective for the global market in every aspect of technological advancements, accuracies, tool room costs and quality of the pipes.

pellet mill dies

30,000 Per unit

pellet mill dies

Get Price Quote

we are a leading manufacturer of poultry and cattle feed machines in india. To cater the growing needs of pellet mill spares, particularly dies, we have imported a cnc gun drilling machine from germany in the year 2009 and have been manufacturing and supplying high chrome dies in stainless steel for the last one and half years. We have already become a preferred vender of many feed manufacturing companies in india and abroad. At present, we are supplying these pellet mill dies to more than 60 companies all over india & abroad, including suguna , japfa , uttra , venkys, shrawasthi feeds etc. as far as quality of die is concerned, we can guarantee for our product in material of steel, hole finish, hardness, heat treatment etc. At par with any brand globally. We can provide you testimonials for the same of those who are using these dies. just give our pellet mill dies a try, and we assure you that you will find its performance at par or better than any other brand in world over in total tonnage or product quality. If you are using conventional dies with simple drilling, please go through the details in product brochure for the advantages you will get using our pellet mill dies. For any more information, please contact the under-signed.

Pellets Dies

2,000 Per Piece