Zirconium Silicate Beads

Crafted under the strict vigilance of experts. Our Zirconium Silicate Beads are comprehensively in demand. We are a renowned Manufacturer, Exporter and Supplier of Zirconium Silicate Beads in India. The Zirconium Silicate Beads that we deal in are widely in demand due to their exquisite finishing. With us, one can choose from a number of colors. The Zirconium Silicate Beads find their usage in making jewelries. Features : Smooth finish Optimum quality Light weight Other Details : SZS-40 Medium Beads SZS beads are manufactured from word-class premium zircon (ZrSiO4) mineral in a special high temperature sintering process because of the high temperature sintering process because of the high breakage resistance, and the advantageous price, this medium density bead is particularly suitable for use in large-volume industrial-scale agitated bead mills.

Color : Off white

Purity : 99.9%

...more

Zirconia Alumina Composite Beads

We have carved a niche for ourselves as a well-known Manufacturer, Exporter and Supplier of Zirconia Alumina Composite Beads in India. The Zirconia Alumina Composite Beads are designed and produced by our professionals keeping in mind the prevailing trends of the market. Offered by us in different colors, the Beads are perfectly polished. They are widely used for decoration and making jewelry. Order big or small, timely execution of the order is assured! Other Details : ZAL beads have unique formula The patented formulations combine the good properties of these two ceramic materials (ZrO2 & Al2O3), bringing the beads excellent toughness as well as high breakage resistance The smooth surface offers extremely low wear to the mill internal components Proven to be suitable for use in both vertical and horizontal high speed bead mills for many griding applications The advantageous prices enable the beads to be good replacement of any other low-medium density products like glass and alumina beads

Hardness : Minimum 1150 HV1

...more

Zircon Sand

Our fast transit facilities make us able to easily meet the expected delivery deadlines of the clients. With stern quality examinations on varied stages of deigning and manufacturing, even the raw inputs used are completely examined by the professionals. This helps us in delivering the finest array of products with complete precision.

Material : Zicron

...more

Zinc Cut Wire Shots for Shot Blasting

Zinc Cut Wire Shot is an ideal abrasive for blasting corrosion resistant steels and non ferrous products, where the risk of ferrous contamination to the surface is not acceptable. SyncZinc™ Shot is manufactured from virtually pure zinc. This enables it to be used in applications where there is a high risk of explosion if an aluminum shot were to be used. This risk is typically manifested when deflashing aluminum components with aluminum shots. The dust generated can lead to an explosive atmosphere as the Aluminum shots are about 10 times more explosive than Zinc Shot, therefore the use of Zinc Shot greatly reduces the risk of explosion. Also,SyncZinc™ Shot is about 2.5 times denser than aluminum shot making it a far superior media for deflashing or deburring of components that would ordinarily not be deflashed or deburred adequately with aluminum shots. Its high density enables it to remove burrs up to 40% in size of the shot’s diameter. Zinc Shot removes burrs 0.5mm thick, whilst an equivalently sized aluminum shot will remove a burr only 0.3 mm thick.

...more

zinc cut wire shots

Material : Zinc

Diameter : 0-10mm

Thickness : 0-5mm

Application : Industrial Use

Color : Metallic

Surface Finishing : Polished

...more

Yttrium Stabilized Zirconium Oxide Beads

We have a strong foothold as an efficient Manufacturer, Exporter and Supplier of Yttrium Stabilized Zirconium Oxide Beads in India. The Yttrium Stabilized Zirconium Oxide Beads that we offer are famous and acknowledged for their super fine finishing and excellent shining. The Yttrium Stabilized Zirconium Oxide Beads are offered by us in several colors and sizes. They are most commonly used to design jewelry. Buyers can place even the bulk orders of the beads with us. Features : Long lasting finish Exclusive designs Light in weight

Hardness : 1250 HV

Bulk Density : More than 3.6 kg/L

...more

Wire Cut Machine

Voltage : 220V

Automatic Grade : Automatic

Driven : Electric

...more

Vibro Finishing Beads

It is all about quality and so we never sacrifice it! We are a trustworthy Manufacturer, Exporter and Supplier of Vibro Finishing Beads in India. The Vibro Finishing Beads, which we offer are available in ample of specifications and shapes. They are widely praised for their superb finishing and precise designing. You can get the Beads from us at the market-leading prices. Order retail or bulk, punctual deliveries are executed. Features : Optimum finish Less maintenance Light weight

Size : 12mm

Type : Beads

Pattern : Printed

Finishing : Polished

Packaging Type : Plastic Box

Feature : Dustproof, Eco Friendly, Light Weight

...more

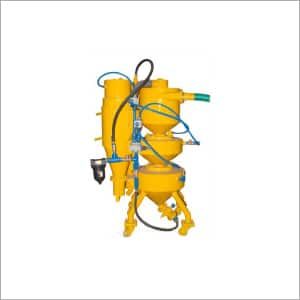

Vacuum Blasting Machine

Features: Noise less operation Power efficient Rugged construction Easy to operate Vacuum Blast Equipment Specifications:Restrictive environmental legislation and a greater awareness of health hazards were the main reasons for development of vacuum blasting equipment. The advantages of the equipment are not limited to preventing environmental and health problems, in many applications it is also a fully justified method of surface preparation on an economic basis. Disposal costs of hazardous waste is minimal by the use of recyclable abrasives, so the amount of abrasives used is much lower than compared with open-blasting. The equipment has many applications. Besides for construction and maintenance of ships, the equipment can also be used for the maintenance of bridges, machinery, power plants or for the renovation of concrete. steel, shipbuilding, offshore and (petro) chemical industries and also for maintenance purpose in the civil works sector such as cleaning bridges , tunnels and buildings etc.The Synco Model : SPBV 08C-1 is a compact and versatile vacuum blasting machine which gives the user flexibility of cleaning components to a depth / height of about 5 mtrs from the machine position. The sturdy construction is designed for rough handling. This model is easy to move to the place of blasting due to its compact size where other machines find difficulty to reach such as submarine holds.

Voltage : 110V

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

Tyre Mould Cleaning Machine

Deposition of foreign material on tyre mold during tyre molding processing is inherent and perpetual problem. After certain number of molding process, these foreign particles need to be removed without affecting the base metal and finish of the mold to obtain consistent quality of tyres. Synco can assist you for development of a blast-cleaning machine for this purpose.

...more

Turbocharger Cleaning Machine

Automobile components like Engine Parts, Turbochargers, Shafts, Fuel System, Bearings, Gears, Pistons, Pulleys, Valves etc. get dirty due to deposition of flue gases, grease, oil, scale and other impurities. These parts are required to be cleaned periodically in order to avoid failure and mal functioning. We supply suction blasting machine for blast cleaning automotive components. In suction blasting machine abrasive is drawn from hopper into the blast gun by a partial vacuum created by high velocity air flow. Induction-suction is suitable for use with light weight abrasives for cleaning of mild corrosion or scale or for achieving fine matte finish. This machine can be operated at a pressure ranging from 4-6 kgf/sq.cm. with light media in order to clean soft metals like Aluminium without dimensional changes. The super blaster ensures continuous working and no interruption in blasting cycle. Major Components of this machine are blasting cabinet, media recycling system, dust collector and control panel.

...more

Tumble Batch Deflashing Machine

Voltage : 220V

Power : 1-3kw

Warranty : 1year

...more

tumblast shot blasting machines

450,000 - 1,500,000 Per piece

1 piece (MOQ)

Special Features : Specially designed Blast Wheel for longer life and efficient blasting Automatic Loading and Unloading arrangement on request Fabric Bag Type or Cartridge Type Dust Collector as desired Machine to be PLC controlled if desired for precised / efficient control Applications of Tumblast Machine : Batch cleaning of metal parts Removal of rust, scale, heat scale and carbon build up from metals Extract residual sand and scale from castings, forgings Deflashing of metal parts

Driven Type : Mechanical, Electric

Color : Blue

Condition : New

Automatic Grade : Semi Automatic, Fully Automatic, Automatic

Power : 1-3kw

Certification : ISO 9001:2008 Certified

Voltage : 220V

Weight : 100-1000kg

Warranty : 1year

...more

Syncut Wire Shots

Diameter : 0-10mm

Thickness : 0-5mm

Color : Metallic

Surface Finishing : Polished

Feature : High Quality, High Tensile

...more

Syncshot Caste Steel Shots

This type of abrasive is a globular product, made of hypereutectoid steel. It corresponds with the international standards and undergoes a fully controlled thermal treatment in the conditions of achieving the optimal resilience and fatigue capacity of the metal. Steel shot is used to achieve the bulk and the maximum kick effect and is mostly applied for shot casting and shot blasting of castings, forgings and rolled products, for surface hardening of the machine building parts, for rolls' ragging and for other technological purposes. SyncShotsTM can be used with Synco make compressed air assisted airless impact blasting machines.

...more

Synco Wet Blasting Machine

The abrasive particles are suspended in liquid, generally water, and pumped to the nozzle in slurry form. The compressed air stream is supplied in the nozzle to increase the velocity and positive pressure when it comes in contact with abrasive slurry. The pressure pump is made up of wear resistant material. Use of wet blaster is recommended for surface finishing operations and light mark. It is also useful in cleaning, deburing holes and precision cutting tools which are inaccessible by any other method. With use of fine abrasive, a surface can be super finished with wet blasting. Please contact us at trideep@synco.co.in for more information.

...more

Synco Paint Spray Rooms

We deal in Paint Spray Rooms to help improve painting quality and maintain a pollution free environment. Vacuum is created with the help of Axial Flow fan and thus air is sucked from outside of the paint room. Air enters through Inlet Filters and so air is filtered and dust and other foreign particles are filtered enabling us to prevent deposition of impurities on job being painted. The air flowing downwards takes the over sprayed paint and passes through paint trap filters where paint particles are filtered and clean air is discharged outside paint room. Paint Trap filters can be replaced periodically.

...more

Synco Glass Beads for Shot Blasting

Glass Beads are an established blasting media for air assisted blasting applications using pressure induction, suction and wet blasting principles and is used for cleaning, conditioning or peening metallic surfaces. SyncoLite™ is manufactured from high‐grade crushed and sized glass cullet, which is melted to a spherical shape and annealed for uniform and controlled internal stresses and superior fracture resistance.These transparent spheres which are non abrasive in nature function without any damage to or dimensional change in the surface of the object embedment, contamination or pick‐up. Depending on the selection of size and operating parameters, SyncoLite™ achieves desired surface finish and texture from fine matte to bright satin. Decorative and special effects are achieved by using masking stencils and blasting exposed surfaces with SyncoLite™. Critically tolerant objects, dies, moulds, component etc. can be cleaned, deburred, textured without removing any base metal, ensuring the sanctity of the critical tolerances due to the intrinsic quality of Syncolite glass beads. In addition, the inherent strength of glass beads allows it to survive multiple impacts, making it extremely suitable for use in closed cycle blasting equipment fitted with recycling facilities. Being chemically inert, and non‐toxic, SyncoLite™ Glass Beads do not leave any unwanted or ferrous residue on blasted surfaces. Spent media which is not contaminated is environmentally harmless.

...more

Synco Flame Spray Gun

In the Flame spray process, the raw material in the form of a single wire, cord or powder, is melted in an oxygen-fuel gas flame. This molten material is atomized by a cone of compressed air and propelled towards the workpiece.

...more

Synco Cut Wire Shots

Cut Wire Shot is a popular alternative to cast steel abrasives, and finds specific applications where cast materials do not offer adequate performance. This is specifically so for peening applications where a higher level of abrasive hardness and uniformity of size is desirable or when components to be peened have a high level of inherent hardness. In order to achieve repeatable peening results, the ideal peening media should contain particles of identical size, shape, hardness and density. Syncut™ are manufactured from wire strand, cut to lengths equal to its diameter virtually identical particles in size, shape, hardness and density and thus a media ideally suited for peening purposes. Syncut™ Carbon Steel and Cut Wire Stainless Steel are supplied in 3 forms depending on the requirements of the application i.e. (A) As Cut (cylindrical with sharp edges), (B) Partially Conditioned (corners rounded off) (C) Fully Conditioned (spherical). Syncut™ in Stainless Steel work hardens with use, resulting in to an extremely long abrasive life span. The almost uniform size range of the Syncut™ particles ensures consistent and repeatable results are achieved when used for surface finishing and treatment of metallic materials. Syncut™ Carbon Steel shots are very versatile and durable when compared to cast steel abrasives, due to virtually no internal flaws, i.e. porosity, shrinkage, cracks etc.

...more

Synco Arc Spray Gun

In the Arc Spray process, the raw material in the form of a pair of metallic wires is melted by means of an electric arc. The molten material is atomised by compressed air and propelled towards the workpiece. This gun is the result of our strenuous R&D Activities which we continually endeavor upon.The combination of the proven, rugged drive mechanism with the high volume air flow capability, together with a new improved nozzle design, truly makes this gun a state-of-the-art arc spray gun.

...more

Syncgrit Chilled Iron Grit for Shot Blasting

SYNCOGRIT CHILLED IRON GRIT is a sharp, hard, angular, metallic impact abrasive media ideally suited for extremely fast impact blast cleaning of steel and iron objects. Its friability makes it break down during recycling to form smaller particles, inheriting the same sharp, angular properties and shape as the original particles. This unique feature of SyncogritTM results in faster cleaning rates and high productivity. As the particle shape is constantly maintained the abrasive is highly suitable when repeatable, consistent surface profile and finish is desired. Syncogrit™ is ideally suited for compressed air blasting application especially when is high production rate is required. It can be appropriately used in SYNCO compressed air dry blasting machines working on pressure induction suction, and pressure vacuum blasting principles. Being lower in cost it is an economical alternative for steel abrasives. It also offers a viable alternative to copper slag or other expendable abrasive media as it can be recycled up to 50 times.

...more

Syncgrit Chilled Iron Grit

We Offer Syncgrit Chilled Iron Grit. Chilled Iron Grit/ CI Grit for shot blasting and sand blasting applications.

...more

Swing Table Blasting Machine

Features: Impeccable performance Easy operation No maintenance Longer service life Swing Table Type Blasting Machine:Previously cleaning with chisel, hammer, wire bushes and screw drivers and other tools for cleaning and removing sand, rust was taking long time, with wheel type shot blasting machine surface finish is achieved in 10 to 15 minutes. Some of the foundries are shot blasting 30 to 40 tones of castings in 12 hours. Shot blasting Improves quality, reduce rejection, saves power and cutting tool cost and adds to the profitability of foundry, forging shops and auto component manufactures. Many small scale units doing job work on this type of machines. Swing Table Type Machines are available with Single Door or Double Door. In this type of machine casting, forging or cylinder heads etc. Must be positioned on table and repositioned to assure complete cleaning of full surface. Component like electric motor body, clutch housing, water pump casing and other components which are fragile, which cannot be tumbled can be successfully shot blasted in swing table machine.

Voltage : 220V

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

Weigt : 100-1000kg

...moreOpening Hours